Case-specific designs improve drill bit performance

Drilling performance can improve dramatically with the use of case-specific bit selection and optimized drilling parameters.

These performance improvements require in-depth analysis and an understanding of complex factors that include rock strength, drilling system, circulating medium, and the entire downhole environment.1

This bit-selection process is more critical for wells with a deviated path or where maintaining hole integrity is a concern.

Bit selection

Historically, operators have used offset well records for selecting bits that will have acceptable drilling performance. These records list the specific bit type used in each zone and provide an insight into optimal weight on bit and rotational speeds.

From this information one also can infer bit life expectancy and footage capabilities of a specific bit.

This approach has proven that it produces highly predictable and repeatable drilling performance. It generates, therefore, a comfortable status quo method for reducing the perceived risk of drilling subsequent wells and has resulted in bit selection being perceived as a commodity in many areas.

This approach, however, does not produce better results. In today's environment of steeper production decline curves, operators face drilling more wells to maintain the same production level. The increased number of wells provides a strong motivation for reducing overall costs that can stretch drilling budgets as far as possible.

This cannot be achieved without challenging the status quo.

In the complex environment for drilling oil and gas wells, it takes more than just a better mouse trap to generate improved drilling efficiency. This is especially true when it comes to drill bits.

Better bits are required along with better bit selection and optimized drilling parameter recommendations.

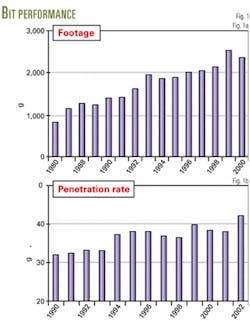

Drill bit manufacturers have a large investment in research programs working to improve drill bit technology and performance. These research and development programs have made step improvements in drilling performance, as reflected in Fig. 1. The figure shows the average improvement in ROP for the past 10 years and the average bit-life improvement of all drill bits for the past 20 years.

The main change in recent years is that bit development, bit selection, and operating parameters have become more customized to a specific application.

This customized solution requires a cooperative effort between research, design engineering, field engineering, technical marketing, and the customer.

In Hughes Christensen Co., this customization is done by the design, application, and research teams (DART). Each functional area within the DART provides input to guarantee the success of the final solution.

Research has at its disposal facilities that include a high-pressure drilling simulator in which bit features can be tested in realistic downhole conditions in the lab before being tested on a full-scale drilling rig at Baker Hughes's experimental test area near Tulsa.

In addition, the research engineers have the benefit of years of research and feature testing experience under diverse operating conditions and environments.

Design engineering has a suite of computerized design evaluation tools that include tools to optimize cutting structure design and layout, evaluate dynamic bit stability, and analyze fluid flow and nozzle placement to optimize bit-cleaning characteristics.

These tools are then applied to a specific drilling situation described by the customer and the local technical marketing representative. The solution includes the bit selected or designed for a specific application, as well as a specific drilling assembly and recommended operating parameters for the application.

New PDC design

As one example of the benefits of new bits designs, an application in Stephens and Garvin counties, Oklahoma, required a new polycrystalline-diamond compact (PDC) design.

Wells in this area in the 1990s were drilled with roller-cone bits, exclusively. A typical well included a 121/4-in. surface hole drilled to about 3,500 ft with IADC Type 116-117 steel-tooth bits. Then between eight and twelve 83/4-in. IADC 427-747 tungsten-carbide insert (TCI) type roller cone bits drilled the hole to TD at about 14,000 ft in the Viola or Bromide (Ordovician) pay-zone.

Penetration rates varied from 15 to 80 fph in the shallower formations with drilling slowing to 2-12 fph in the harder formations at the bottom of the hole.

Drilling time for a typical well averaged 53 days.

In early 2000, operators began drilling the wells in the area with PDC bits.

Initially in these two counties, PDCs drilled only the relatively soft sections below surface down to the Tonkawa formation at 5,500-6,100 ft. One 83/4-in. PDC replaced two to three steel tooth or TCI bits in the faster drilling roller-cone sections. This reduced drilling time by about 2 days.

Following the PDC bit run were three to four IADC Type 427-537 TCI bits that drilled to about 8,900 ft, reaching the Woodford formation which contains hard shale and chert. Harder formation IADC Type 537-747 TCI bits then drilled to TD, typically in Viola limestone at about 14,000 ft.

Some wells continued down into the Bromide formation that contains a combination of hard shale, sand, and limestone. Impregnated diamond bits or hard formation TCI bits, historically, drilled this section.

Later in 2000, engineers reexamined earlier findings to determine the possibility of further drilling performance improvements.

The first step analyzed the formations and the demands required from a bit design. In general, the lithology included interbedded limestone and sandstone stringers with compressive strengths up to 40,000 psi.

The analysis indicated that a PDC bit could be specifically designed for drilling the Tonkawa formation, at 5,500-6,100 ft, faster than the current bits in use. Also the new design could continue to drill to 7,100-7,700 ft at penetration rates comparable to TCI bit rates.

The design-application team had the final goal of designing a single bit that could drill to the top of the Woodford (8,600-9,000 ft) faster than insert-type bits in the same interval.

This objective required a paradigm shift in bit application philosophy and drilling techniques in the area. A new benchmark was established in the area by focusing on application-specific requirements, applying the DART team approach, and introducing new technologies.

The eventual solution was a new 83/4-in. HC606 PDC bit (Genesis). This bit (Fig.2) is a fairly heavy-set, six blade, six-nozzle design that provides excellent durability and is a good match for the hydraulic capabilities of the rigs in the area.

The capability of drilling from under the surface hole to the top of the Woodford with one PDC bit decreased the drilling time from the 53 days required in the 1990s to 23 days or less (Fig. 3).

In Stephens and Garvin counties, consistent use of the design-application process, coupled with new PDC designs have reduced bits per well and drilling days to TD by more than 40% and increased the average footage drilled/bit from 729 ft with TCI bits in 1990 to 4,815 ft by PDC bits in 2002.

In some cases, a single run is drilling the entire interval from under the surface hole to the top of the Woodford. The record to date is 8,343 ft in Garvin County at a rate of penetration (ROP) of 40.4 fph.

Impregnated diamond bits

In another example, impregnated diamond bits, historically, have had a narrow application range. Drilling typically limited these bits to deep intervals of reasonably homogeneous hard and abrasive sandstone.

null

Bit-balling issues resulted in formations with interbedded sections of soft, nonabrasive rocks (shale) being drilled with roller-cone bits.

The inability of impregnated bits efficiently to drill soft rock stringers was a major limiting factor for running the bits in areas where otherwise they would be the most economical option.

Recognizing these limiting issues, Hughes Christensen's research and development department tested various concepts to overcome the problem. This work eventually led to a new bit that greatly expanded the application range of impregnated bit technology.2

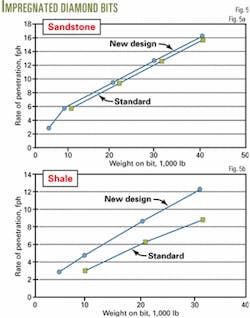

A number of controlled drilling tests run under identical conditions and with identical rock in a full-scale drilling simulator in The Woodlands, Tex., highlighted the significance of this new impregnated technology (HedgeHog).3 Fig. 4 shows the bit and Fig. 5 compares the performance of the new style bits and the traditional impregnated bit.

When drilling sandstone, the new impregnated HH design showed increased ROP of 5-10% when compared to the best conventional impregnated design. But the true value of this new technology is its ability to drill 30% faster than conventional impregnated designs in problematic shale formations.

The real test, however, would be in the Hassi Massaoud field in Algeria for Sonatrach-Forag.

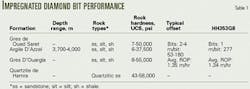

The Grés de Oued Saret and Grés D'Ouargla formations in this area have unconfined compressive strengths up to 58,000 psi interbedded with soft, nonabrasive shale sections.

After thoroughly evaluating the application, the engineers modified a 6-in. HH353G8 for this application. Because of the higher rock strength, they replaced the PDC cutters normally placed in the cone with ridge-set thermally stable synthetic diamonds (TSP).

This innovative cutting structure, along with a new hydraulic design and advanced matrix types contributed to the success in this application. Table 1 compares this run against the best offsets in the field.

The 6-in. HH352G8 drilled from 3,741 to 4,018 m, a distance of 277 m from the top of the Grés de Oued Saret through the Argile D'Azzel, the Grés D'Ouargla, and 23 m into the Quartiztes de Hamra at a cumulative ROP of 1.34 m/hr.

On the first run, the bit produced the longest 6-in. bit run through the Grés de Oued Saret to Quartzites de Hamra formations in the Hassi Massaoud field, drilling 97 m farther than the best offset run and replacing the two planned bit runs through this interval.

This was a major shift in performance that has been repeated several times dramatically to reduce drilling costs in Hassi Massaoud field.

Roller-cone bits

The rate at which new drill bit technologies have been introduced in recent years has increased dramatically. Improved research tools and investment are part of the reason, but another major contributing factor is reduced cycle time required to manufacture new roller-cone bit designs.

Cycle time can be measured in two ways. One includes the time required to design, manufacture, and ship a new bit to location. The second only looks at manufacturing time.

About 20 years ago, total cycle time to design and produce a new roller-cone bit averaged about 9 months. Manufacturing time was about 6 months.

It was apparent that bit companies needed to optimize retooling of the manufacturing equipment to expedite delivery of new bits to the field.

They took several steps to reduce the cycle time.

First, they introduced new numerically controlled (NC) production equipment and processes that dramatically reduced the number of required set-up steps, improving component quality at the same time.

The new processes were optimized by using software programming that produced real-time data that enabled engineers to optimize component flow through the factory.

Ongoing analysis of the data further reduced queue time for low-count to multiple-quantity orders by decreasing set-up and flow constraints. In the process, an elaborate alphabetical sequence system is implemented for each component outlining the order the part is to be processed, including day and shift.

A cycle timeline with gates and latches also targets each area's individual cycle time and on-time delivery. Progress reports are daily.

Communication, teamwork, and flexibility are the keys for keeping component parts on schedule. Engineers also have new bit design tools that produce machine-ready drawings as a direct output of the design process.

These major improvements have reduced overall cycle time and improved product quality. Today, total cycle time rarely exceeds 1 month and manufacturing cycle time has been reduced to 10 days or less.

The first step in an effective product-development effort is correctly to identify the problem. This information is generally fed to R&D from field personnel and establishes the specific performance expectations needed by the operator.

A team effort is then initiated to design a new drilling solution that will produce the desired performance.

After the design concept is complete, the next step requires the cooperative efforts of marketing, materials, engineering, processing, and manufacturing to deliver the new bit to the customer in the agreed time frame without compromising quality.

This process was used to produce a series of bit-design iterations dramatically to improve drilling performance in hard-rock applications in East Texas for Devon Energy Corp.4

The normal delivery time for a bit design iteration would be 1 month. But because of the operator's requirements, Hughes Christensen designed, manufactured, and shipped two 77/8-in. HR-88DX bits in just 8 days.

The actual manufacturing cycle time was a record 2.8 days. Even more impressive, the 77/8-in. HR-P88DX set a single-run footage record of 1,537 ft in Freestone County in September 2002.

In the area, this footage is more than other 77/8-in. bits with a IADC code of 637 or higher,.

Cycle-time reduction has streamlined the time frame from design concept to the delivering new cost-cutting technology to the rig floor. It also has improved bit quality by allowing better initial designs because of the closer communication between the operator, engineering, research, and manufacturing.

Cycle-time improvements never end. Manufacturing and engineering departments continue to incorporate process improvements to shorten queue and cycle times.

References

1. Turner, E.C., "Field Specific Analysis Reinforces Role of Bit Technology in Improving Overall Drilling Economics," Paper No. SPE/IADC 37642, SPE/IADC Drilling Conference, Amsterdam, Netherlands, Mar. 4-6, 1997.

2. Brackin, V., et al., "Expanding the Range of Impregnated Technology: New Performance Benchmark Set in Middle East," Paper No. SPE 74524, IADC/SPE Drilling Conference, Dallas, Feb. 26-28, 2002.

3. Isbell, M.R., and Berzas, S., "Re-Engineered Drilling Laboratory is a Premium Tool Advancing Drilling Technology by Simulating Downhole Environments," Paper No. ETCE 99-6653, Energy Sources Technology Conference and Exhibition, Houston, February 1999.M

4. Martin, D., and Jacobsen, J., "New Hard Rock Roller Cone Bit Technology/Operational Excellence Improves Economics in Mature East Texas Gas Fields," Paper No. SPE 74527, IADC/ SPE Drilling Conference, Dallas, Feb. 26-28, 2002.

The authors

Shelly Cory is tricone product application engineer for Hughes Christensen Co., The Woodlands, Tex. Prior to Hughes Christensen, she worked as an ASME code designer inspector and marketing manager. Cory has a BS in mechanical engineering from Texas A&M University. She is an ASME and SPE member.

Evan Turner is director, marketing services for Hughes Christensen Co., The Woodlands, Tex. He has worked previously as an oil company economist, product manager, and district and region operations manager. Turner holds a BA and an MS in economics from Brigham Young University. He is an SPE member.