Numerous studies analyze CO2 sequestration options

Starting in the 1990s, various government, academic, and industry organizations have initiated studies to determine the best methods for mitigating the excess carbon dioxide entering the atmosphere from human-made (anthropogenic) sources.

Excess CO2 in the atmosphere contributes to a greenhouse effect that increases global temperature, which potentially can harm all life on earth.

Fig. 1 illustrates the expansion in the number of projects that focus on geologic sequestration of CO2. Besides geological sequestration, studies also have concentrated on determining the best and most economic technology for removing CO2 from emissions at such industrial sites as power, fertilizer, cement, chemical, refining, and natural gas plants. Once separated, the CO2 would then be transported to appropriate sites for injection.

Most of the world’s experience with CO2 injection relates to enhanced oil recovery (EOR) projects such as the large ones in the Permian basin of West Texas and New Mexico. These projects mostly use natural CO2 from geologic formations and involve an extensive infrastructure that includes wells for producing CO2, pipelines to transport CO2 to the oil fields, wells to inject CO2, and facilities either for separating and reclaiming the produced CO2 before it is reinjected or for reinjecting the entire produced gas stream without separating out the CO2.

Even with this experience, the heterogeneous nature of subsurface geology makes the numerous additional studies necessary, especially from the viewpoint of governments and the general public with its “Not in my backyard” mentality.

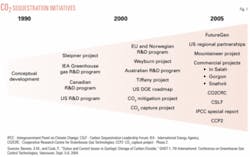

As Fig. 2 shows, CO2 injection does have potential risks. These include CO2 leaks into ground-water layers, lakes, topographic depressions, building basements, or to the atmosphere. CO2 is not a poisonous substance, but it will displace oxygen from a confined or low area.

Injection of human-made CO2 into oil fields to improve oil recovery is one of the more economic attractive options, but costs are high even taking into account the studies that estimate that many millions of bbl of additional oil could be recovered. For instance the Gulf Coast Carbon Center, operated by the University of Texas Bureau of Economic Geology, estimates that outside of the Permian basin area, CO2 injection in Texas could recover an additional 5.7 billion bbl of oil and lead to the storage of 0.7 billion tonnes of CO2. Also Advanced Resources International (ARI), Arlington, Va., has estimated that CO2 EOR in the US could potentially recover 43 billion bbl of oil of additional oil.

CO2 injection of about 1.2 bcfd in the Permian basin is currently recovering about 180,000 bo/d and one estimate is that companies producing in the basin have recovered an additional 1 billion bbl of oil because of CO2 injection.

But in either the case of human-made CO2 being injected into oil fields or other geologic formation, these operations will require some government incentives and probably a new industry for building the costly infrastructure to recover, transport, and inject the CO2, as well as to provide long-term monitoring of the injected CO2.

ARI estimates that the global sequestration capacity in depleted oil and gas fields is 923 billion tonnes, which equates to 125 years of current worldwide CO2 emissions from fossil fuel-fired power plants. Norway has said recently that CO2 injection for improving oil recovery from its offshore fields would not start in the near term, if at all. A study by the Norwegian Petroleum Directorate (NPD) determined that EOR with CO2 off Norway was too expensive and risky (OGJ, Aug. 8, 2005, p. 37). This assessment said that the main impediments were the expense of building a network for delivering CO2 to the fields and the high estimated $30-33/bbl cost of the oil recovered.

Carbon dioxide

Measurements indicate that CO2 from the burning of fossil fuel has continued to increase because the natural global carbon cycle is not removing all of the CO2 being emitted to the atmosphere.

In the carbon cycle, green plants remove or sequester carbon from the atmosphere through photosynthesis. This process separates the carbon atom in CO2 from oxygen atoms, returning oxygen to the atmosphere and transforming carbon into biomass such as roots, stems, and foliage.

Convenient conversion factors are:

• 3.67 tonnes of CO2 equals 1 tonne of carbon.

• 19 Mscf of CO2 equal 1 tonne of CO2.

The US Energy Information Agency (EIA) Inventory of Greenhouse Gas Emissions 2003, published in December 2004, shows that CO2 during the 1990s was increasing in the atmosphere by about 11.7 billion tonnes/year. The value is derived from the 770 billion tonnes/year of CO2 from natural sources plus 23.1 billion tonnes/year from human-made CO2 sources less 781.4 billion tonnes/year of CO2 absorbed by the carbon cycle. This imbalance between CO2 absorption from and emissions to the atmosphere is not a recent phenomenon. The report notes that Antarctic ice cores show that the imbalance has persisted for the last 200 years, resulting in a continual increase of CO2 in the atmosphere.

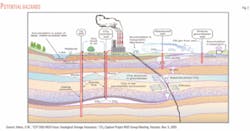

The report estimates that the worldwide human-made CO2 emissions in 2003 were 25.1 billion tonnes/year. Broken down by fuels, the CO2 emissions are as follows (Fig. 3):

• Petroleum: 10.5 billion tonnes/year.

• Natural gas: 5.3 billion tonnes/year.

• Coal: 9.3 billion tonnes/year.

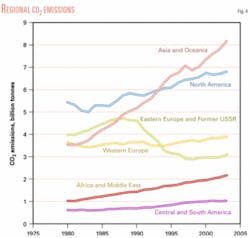

Fig. 4 shows that Asia and the Oceania regions have overtaken North America as the region emitting the greatest amounts of CO2. The three countries in Asia and Oceania regions accounting for the most of these emissions are: China (3.5 billion tonnes/year), Indonesia (1.2 billion tonnes/year), and India (1.0 billion tonnes/year).

The US still is the country that emits the most human-made CO2. EIA’s estimate is that in 2003 the US emitted 5.87 billion tonnes/year of CO2, of which 2.3 billion tonnes/year came from electric generation. Coal-fired electric generating plants emit most of this CO2, about 1.9 billion tonnes/year.

Current CO2 injection

Besides the injection of natural CO2 in EOR projects, a number of projects already inject human-made CO2 either for enhancing oil recovery or for sequestration.

Encana Corp.’s Weyburn EOR project in Saskatchewan injects CO2 supplied in a 204-mile pipeline from the Dakota Gasification Co.’s Buelah, ND, synfuels plant that converts coal to methane gas.

Encana currently injects up to 95 MMcfd of CO2, but Dakota Gasification says that this will increase by 32 MMcfd in July 2006 after it installs a third compressor at its Buelah plant. The added compression will also allow Dakota Gasification to sell 25 MMcfd to Apache Canada Ltd.’s Midale EOR project, also in Saskatchewan. With this expansion, all Dakota Gasification CO2 output essentially will be sold.

Pan West Petroleum Ltd.’s Joffre Viking CO2 flood in Alberta is another EOR project in Canada that uses human-made CO2. The project receives about 3-4 MMcfd of CO2 from the nearby NOVA ethylene-polyethylene plant.

In the US, PetroSource Energy Corp., Midland, Tex. supplies about 75 MMcfd of CO2 to Permian basin CO2 floods through an 82-mile pipeline from the Terrell, Mitchell, Gray Ranch, and the recently tied in Pikes Peak gas plants in the Val Verde basin of southwest Texas.

Anadarko Petroleum Corp.’s Salt Creek and Monell Unit CO2 floods in Wyoming receive vented CO2 from ExxonMobil Corp.’s LaBarge gas processing plant in Wyoming. LaBarge also supplies CO2 to Chevron Inc.’s Rangley CO2 flood in Colorado and Merit Energy Co’s CO2 floods near Baroil, Wyo.

Another US human-made CO2 source that supplies CO2 to EOR projects is a fertilizer plant in Enid, Okla. Its CO2 goes to Chaparrel Energy’s Sho-Vel-Tum flood and Anadarko’s Northeast Purdy and Bradley Unit floods.

BP has targeted the nearly depleted Miller field in the North Sea as the recipient of CO2 generated from the reformer in its planned 350 Mw combined-cycle, gas-turbine power plant, near Peterhead in Scotland, that will covert about 70 MMscfd of natural gas to hydrogen and CO2. The hydrogen will fuel the plant while the CO2 will be piped 240 km to the Miller field for injection to improve oil recovery and CO2 sequestration. BP says it will make a final decision on the 600 million “carbon-free electricity from hydrogen” project in 2006 and expects operations to commence in 2009.

When fully operational, BP expects the project to capture and store about 1.3 million tonnes/year of CO2 with the CO2 EOR in the Miller field recovering about 40 million bbl of oil during 15-20 years of extended life.

Miller began production in 1992 and is in 100 m of water. Production peaked in 1995 at 150,000 bo/d and 220 MMcfd of gas and the field currently produces 10,000 bo/d and 15 MMcfd of gas.

Other CO2 sequestration projects in the world include Statoil ASA’s project that removes CO2 from the produced gas on the Sleipner West platform off Norway and reinjects it for storage in an aquifer. Sleipner’s produced gas contains about 10% CO2, and Statoil has to remove much of the CO2 to meet the 2.5% CO2 sales specification.

For CO2 removal, Statoil uses an amine solvent to absorb the excess CO2 before injecting the CO2 into an aquifer at about a 3,000-ft depth. It sequesters about 1 million tonnes/year of CO2.

Statoil also has plans to reinject into an aquifer the CO2 removed from gas produced from its Barents sea, Snøhvit development (OGJ, Nov. 25, 2002, p. 38). It expects Snøhvit to produce gas containing 5-8% CO2. Separation of the CO2 will take place onshore and before it is piped back to the Snøhvit subsea development for injection into a 45-75 m thick sandstone at about 2,600 m below the seabed. Statoil expects to inject about 700,000 tonnes/year of CO2 into the sandstone.

Another project in which Statoil is a participant along with the operator BP PLC and partner Sonatrach, Algeria’s state-owned oil company, is CO2 injection in the Salah field in Algeria. The project will store about 1 million tonnes/years of CO2 in a gas reservoir.

Sequestering CO2 in deep saline formations is another possibility. The DOE estimates that deep saline formations in the US could potentially store up to 500 billion tonnes of CO2.

Besides EOR and storage in aquifers, some natural gas plants, especially in Canada, are sequestering in geologic formations low-pressure CO2 with H2S primarily because sulfur recovery from the produced gas has little value. This acid gas is first compressed before being injected into a suitable underground zone, similar to produced water disposal.

Studies

Various studies including pilot projects have assessed the potential of CO2 injection. The Allison Unit and Tiffany projects in the San Juan basin of Arizona provided information on the potential for recovering additional gas from coalbeds with CO2 and nitrogen injection (OGJ, July 14, 2003, p. 49). The studies were part of a multiyear government-industry research and development (R&D) collaboration, the Coal-Seq project, launched in October 2000 by the US Department of Energy (DOE) through its contractor ARI.

Burlington Resources Inc. operates the Allison Unit while BP America Inc. operates the Tiffany Unit.

Scott Reeves of ARI says that coalbeds have a limited potential for CO2 sequestration but the studies, such as Coal-Seq II, are continuing and will assess the potential for recovering with CO2 injection additional gas from the coalbeds in the San Juan basin as well as in the Antrim shale of Michigan and the coalbeds in the Appalachia.

Research also is ongoing into disposing of CO2 in the deep ocean, although this option is less likely to provide longer-term storage compared with some geologic formations in which CO2 might reside for millions of years.

The length of time CO2 can remain in a geologic formation is still under study. In one study, ARI is examining field geology and production operations at three producing natural CO2 deposits in the US. It says these sites (McElmo Dome, St. Johns Dome, and Jackson Dome) provide excellent natural analogs for verifying that CO2 can remain in formations for millions of years.

In another study, an international group of organizations with the University of Regina, Saskatchewan is using such technology as 4D seismic to examine the cap rock integrity to verify that CO2 will remain in the reservoirs in Encana Corp.’s Weyburn CO2 flood.

The Gulf Coast Carbon Center (GCCC) is starting the second phase of its tests of carbon sequestration in a Frio well in Liberty Co., Tex. GCCC estimates that the Gulf Coast region emits about 1 billion tonnes/year of CO2, about 3.9% of the world total.

Another project entering its second phase is the BP-led CO2 capture project (CCP). Charles Christopher of BP said that during the first phase of the project, studies determined that geological sequestration of CO2 was feasible and the second phase would validate these conclusions with several field trials.

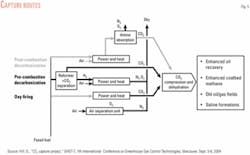

One aspect of the CCP project analyzed the most effective way to capture CO2 power-plant emissions. The three capture routes are post-combustion decarbonization, precombustion decarbonization, and oxy firing (Fig. 5).

The Global Climate and Energy Project (GCEP) is another large project, initiated at Stanford University in 2002 by ExxonMobil Corp., GE Corp., Schlumberger Ltd., and Toyota Corp. The $225-million project during a 10-year period aims to develop commercially viable technologies for reducing global emissions of greenhouse gases. Its research activities are wide-ranging and include geologic sequestration of CO2.

US regional partnerships

The US Department of Energy is providing funding to seven regional partnerships to further develop carbon sequestration technologies as part of its strategy to reduce by 18% greenhouse gas intensity by 2020.

The seven partnerships involve public and private sector consortia of businesses, state agencies, and universities that were initially established in 2002 to research carbon sequestration.

During 2004-08, these partnerships are field testing and validating carbon sequestration technologies that are best suited to their respective regions, and are involved in conducting public outreach, satisfying permitting requirements, and identifying best-management practices for future deployment, according to DOE.

DOE says that the network of regional partnerships includes more than 240 organizations in 40 US states, three Indian nations, and four Canadian provinces. An information gateway called NATCARB, developed by the University of Kansas, will collect the data generated by the partnerships.

DOE sees these projects as also critical to its FutureGen power plant design, which is a highly efficient and technologically sophisticated coal-fired power plant that will produce both hydrogen and electricity without emissions.

Table 1 lists the seven partnerships, and a brief summary of their goals is as follows:

1. Big Sky Regional Carbon-Sequestration Partnership will demonstrate long-term CO2 geologic storage in mafic and basalt rock formations. DOE estimates the Columbia River basalt area could store about 30 years of CO2 from all US coal-fired power plants. Montana State University heads the partnership that has at cost of $17.9 million, with 79.5% provided by DOE.

2. Midwest Geological Sequestration Consortium-Illinois Basin aims to evaluate the safety and capacity of storing CO2 in deep coal seams, mature oil fields, deep saline reservoir formations, and organic-rich shales of the Illinois basin.

The University of Illinois and Illinois State Geological Survey head the consortium and plan to conduct six small-scale sequestration field tests in depleted oil and gas fields, saline reservoirs, and unmineable coal seams to assess whether these sites can store a portion of the 276 million tons/year of CO2 emitted from fixed sources in the Illinois basin. DOE will fund 82.1% of the $19.8 million cost of the project.

3. Midwest Regional Carbon Sequestration Partnership plans to conduct at least three small-scale CO2 injection field tests in deep geologic reservoirs having more than 200 years of storage capacity. The partnership will also conduct small-scale terrestrial sequestration field tests to demonstrate measurement techniques associated with carbon storage and will monitor how carbon credits can be traded in voluntary greenhouse gas markets.

Battelle Memorial Institute heads the partnership. DOE will fund 79.1% of the $18.1 million project cost.

4. Southeast Regional Carbon-Sequestration Partnership will define the potential for storing CO2 in three field sequestration validation tests in three target geologic formations: enhanced oil recovery stacked reservoirs, coal seams, and saline reservoirs. Southern States Energy Board, Norcross, Ga., heads the partnership. Project cost is $20 million, of which DOE will fund 71.6%.

5. Southwest Regional Partnership for carbon sequestration will conduct five field tests (three geologic, two terrestrial) to validate carbon-sequestration technologies and infrastructure concepts. The tests represent a variety of carbon-sink targets, including deep saline sequestration, enhanced oil recovery and sequestration, enhanced coalbed methane production, and geologic sequestration tests combined with terrestrial tests.

New Mexico Institute of Mining and Technology heads the partnership. DOE will fund 80% of the $17.9 million project cost.

6. Plains CO2 Reduction Partnership will conduct four technology validation field trials and two investigations of sequestration concepts. The field trials will involve CO2 storage, comprehensive monitoring, and mitigation in depleted oil and gas reservoirs, unmineable coal seams, and restoration of wetlands.

The University of North Dakota Energy & Environmental Research Center heads the project. Project cost is $21.5 million, of which DOE will fund 62.7%.

7. West Coast Regional Carbon Sequestration Partnership will conduct two CO2 tests in California and one in Arizona to assess CO2 storage in depleting gas reservoirs and saline formations as well as two other formations. The California Energy Commission heads the projects. DOE will fund 47.8% of the $30 million project. ✦