Single-station mandate forces Gulfstream to adopt unusual design

Design of Station 100 for the Gulfstream Natural Gas System incorporated several features not normally found in a traditional natural gas transmission system compressor station.

These features were necessary to allow movement of 1,130 MMscfd of natural gas from supply sources in southern Alabama and Mississippi across the eastern Gulf of Mexico to delivery points in central Florida (Fig. 1) using the single compressor station and to prevent liquid condensation in the cold gulf pipeline segment.

The station design was also based on the fundamental concept of providing for the highest on-line reliability and incorporates the latest technology in both equipment and controls.

During the conceptual stage, Gulfstream decided for both economic and environmental reasons to install one compressor station, Station 100. This article provides background information and describes special features in the design of Station 100.

Gulfstream is owned by affiliates of Duke Energy Corp. and Williams Gas Pipeline, part of Williams Cos. Inc.

Project development

Florida's rapid population growth and ensuing need for additional electrical power prompted development of the Gulfstream Natural Gas System. Based on the 2001 10-year site plan filed by Florida's generation utilities, incremental power-generation estimates for the end of 2005 will be near 11,000 Mw.

Clean-burning natural gas is preferred for new electric-power generators for both environmental and economical reasons. To meet the projected demand for power generation alone, the natural gas supply into Florida must increase by more than 2 bcfd.

The US Federal Energy Regulatory Commission (FERC) approved the 753-mile Gulfstream system originating with Station 100 and consisting of 437 miles of 36-in. offshore pipeline and 316 miles of 36, 30, 24, 16, and 8-in. of onshore pipelines with 17 meter stations. Three additional meter stations (including two interconnects with FGT) were added in subsequent filings.

The initial build out of the system includes the offshore pipelines, 163.5 miles of the onshore system (upstream receipt lines in Mississippi and Alabama plus 159 miles in Florida) and 18 meter stations. The remaining Florida facilities will be constructed when required by market conditions.

Gulfstream chose Willbros Engineers Inc. in March 1999 to provide overall project management including the necessary engineering services to assist the company in preparing the FERC application and to perform detail design engineering for the entire project.

Willbros in turn selected ABB Randall to assist in the conceptual design of the gas-treatment facilities at Station 100. Gulfstream also selected ENSR Corp., an environmental contractor, to assist in preparing the project environmental assessments and any Station 100 environmental construction permits.

From its inception, the project has been on a fast track. Gulfstream reasoned that if it could be the first to place its pipeline system in service, it would have a distinct advantage with potential shippers over other competitors. Consequently, the company developed an aggressive schedule to achieve an in-service date of June 1, 2002, well ahead of the competition.

Gulfstream's efforts to "fast track" the project were successful: It was the first to have a FERC application accepted and the first to receive a FERC certificate. Key to this process was an approach called Team Permitting used by the various regulatory agencies in Florida with the Florida Department of Environmental Protection (FDEP) as the lead agency. This approach was the first time the process was used on a pipeline project in Florida.

Environmental impacts on design

Before submitting the FERC application, Gulfstream perceived two environmental issues concerning operation of the initial station in Florida (Station 200) that could present major roadblocks to obtaining approval for its project. These issues, which affected the design of Station 100 in Alabama, consisted of the disposal of any liquids received in Florida and the emissions, noise, and aesthetic appearance of any gas treating or compression facilities.

Consequently, Gulfstream adopted the policy that no liquids would be transported into Florida, thus eliminating the need for gas treating and liquid handling facilities there. Implementing this policy required that gas-treating facilities be added to Station 100 to reduce the hydrocarbon and water dew points of the transported gas to temperatures cooler than the coldest expected environmental temperature in the Gulf of Mexico subsea pipeline segment.

An added benefit of this policy was that an operational spill-prevention plan was not required by the US Department of Interior's Minerals Management Service for the offshore portion of the pipeline into Florida.

Elimination of compression facilities at Station 200 required an unusually high station discharge pressure of 2,180 psig at Station 100 in order to transport the gas to all sales points in Florida.

Gas quality control

Gas shipped through the Gulfstream system originates from various production in Alabama and Mississippi (Fig. 1). Relevant portions of the gas-quality tariff specifications at each receipt point follow:

- Heat content not greater than 1,075 btu/std. cu ft nor less than 1,000 btu/std. cu ft.

- Hydrocarbon dewpoint less than 25° F. at 800 psig.

- No free water nor more than 7 lb/MMscf of water vapor.

- Not contain more than 4 ppm (0.25 grains/100 cu ft) of hydrogen sulfide.

- Not contain more than 10 grains/100 cu ft of total sulfur.

Should any gas tendered for shipment fail to conform to the tariff specifications, Gulfstream must notify the supply source and may, at its option, suspend receipt of all or a portion of the tendered gas. Because the burden of responsibility for determining out-of-specification gas is upon Gulfstream, several types of analyzers are at each Gulfstream receipt meter station to monitor gas quality. Specifically, the following analyzers provide information to the gas control center for quality control of the inlet gas to Station 100: gas chromatograph, moisture (water), hydrocarbon dew point, and hydrogen sulfide.

Gas delivered to users in Florida must by contract meet the same tariff requirements previously noted for the inlet gas.

Because of Gulfstream's policy that no liquids be transported into Florida, however, the station discharge gas-quality specification for water content must be limited to 5 lb/MMscfd and the hydrocarbon dew point to 20° F. at 800 psig, which is less than the tariff requirements.

Analyzers of the same type used at the receipt meter stations are also installed at strategic locations within Station 100 to monitor operation of the gas-treating equipment and to ensure that the discharge gas meets the gas-quality specifications. In the event that the gas stream at the station discharge is not within specification, a recycle loop will be employed to route the gas stream from the station discharge back to the station inlet to be reprocessed, thus guaranteeing no out-of-specification gas enters the discharge pipeline.

The station discharge also includes a total sulfur analyzer, installed at the request of the MMS, which can also automatically cause gas to be recycled to the station inlet for reprocessing should the tariff requirements be exceeded.

All analyzers are designed to alarm before the control system automatically takes any corrective action at levels exceeding the discharge gas-quality specification. Upon receipt of an alarm condition, the operator at the gas control center may review the composition of the various gas supply streams, identify possible malfunctions of equipment, and take corrective action to prevent the station from going into recycle mode.

Station facilities

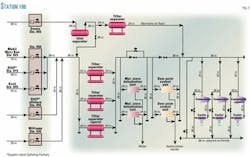

Station 100 consists of three major operating units to compress and treat the transported gas plus all necessary ancillary equipment and support facilities (Fig. 2).

To achieve the highest on-line reliability and maximum flexibility, the station equipment configuration consists of two 50% capacity gas-treating trains and two operating compressors plus one standby compressor.

The dehydration unit consists of two parallel molecular sieve trains and a bypass designed to treat a portion of the total station throughput and then blend the dehydrated gas with the bypassed gas. The amount of gas bypassed is automatically controlled based on the moisture content of the commingled stream downstream of the dehydration equipment and is designed to range from 0% to 25%, depending on the inlet gas composition.

Water content of the gas stream from the dehydration unit is controlled at a set point of 2 lb/MMscf water vapor to prevent hydrates from forming in the hydrocarbon dew point control unit. At 2 lb/MMscf, the water content of the transported gas is significantly less than the 5 lb/MMscfd required for transmission through the Gulf of Mexico pipeline segment and 7 lb/MMscfd required by the tariff, resulting in an added benefit to Gulfstream's Florida customers.

The hydrocarbon dew point control unit consists of two parallel processing trains to cool the inlet gas to a temperature sufficient to condense the desired fraction of heavier hydrocarbon components.

Each processing train consists of a gas-gas exchanger, chiller, and cold separator designed to produce a hydrocarbon dew point of 20° F. at 800 psig, also less than required by the tariff. The two trains share a common propane refrigeration system with three 50% capacity propane compressors for reliability.

Liquid hydrocarbons removed in the hydrocarbon dew point control unit are stabilized to remove the lighter hydrocarbon components and then transported to another facility. Initially, the produced hydrocarbon product is being removed via truck loading but it is anticipated that a pipeline will convey future shipments.

The compression units consist of three 37,900-hp ISO gas-turbine-driven centrifugal compressors.

The selected units were Dresser-Rand D10P4S centrifugal compressors driven by Rolls Royce Coberra 6562 DLE (dry low-emission combustion system) gas turbines through gearboxes. In order to increase power output and efficiency on hot days, each gas turbine contains an evaporative cooling system in the inlet filter house to cool the combustion air to the gas turbines.

The compressor units were specified to deliver the design throughput with two operating units and the remaining unit in standby.

Each compressor unit has a dedicated gas after-cooler to cool discharge temperatures (which can reach 270° F. at the station design throughput conditions) to normal pipeline transmission temperatures. In addition, dedicated gas after-coolers aid in unit start-up and allow the units to idle for long periods.

Two 6-Mw natural gas fueled standby emergency generators provide sufficient electrical power to operate both gas-treating trains and two gas compressor units if commercial power is lost.

Design issues

The design of Station 100 required that selected equipment and station controls have the flexibility to handle a wider range of operating conditions than are normally found in a traditional gas-treating plant or transmission station.

Other major issues that had to be addressed during detail design included the short delivery time available for high pressure, high-temperature station discharge piping materials, and unusual site design conditions.

The gas entering the station will normally have a low hydrocarbon dew point and water vapor content. Whenever any of the upstream treating plants go off-line, however, either for economic reasons or because of a process upset, the gas-treating facilities must have the flexibility to adjust to changing conditions in order to ensure that the tariff is not violated.

Otherwise, Gulfstream would have to interrupt service, resulting in major consequences to the power plants in Florida. The need to handle these possible variations in inlet-gas composition led to development of three separate design cases that reflected the possible range of volumetric mix and corresponding compositions. The gas-treating facilities were then designed for the richest composition.

For other composition cases, portions of the inlet gas stream would bypass the treatment facilities as described previously. Initially, the gas treating will be operating continuously to ensure that the tariff is met.

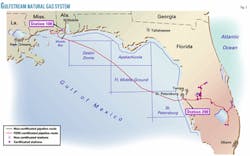

The estimated buildup of transported volumes was based on the projected growth and annual variation of electrical power demand in Florida (Fig. 3). Gulfstream's marketing organization initially estimated the volume buildup would occur over the first 2 to 3 years of operation.

Gulfstream determined that it was neither economically feasible nor desirable from an operations point of view to make frequent compressor wheel changes to meet these changing requirements. Dresser-Rand, however, was able to provide a four stage, high volume, high-head compressor wheel selection with acceptable efficiencies to meet the full range of design conditions.

Piping and equipment design for the compressor discharge conditions was also a major issue due to short-term deliveries required to meet the project schedule.

Station discharge piping was designed for a maximum operating pressure of 2,180 psig, with a maximum compressor discharge temperature of 300° F., and an after-cooler discharge temperature of 120° F.

These operating conditions required Class 1500 flanges on the compressor discharge and Class 900 flanges downstream of the after-coolers. Gulfstream specified heavy-wall pipe and fittings of a grade that would avoid the additional costs associated with field stress relieving of the welds during construction. Gulfstream was able to select vendors with either manufacturing space available or to arrange for expedited delivery in order to meet the project schedule.

With Station 100 located near the Gulf Coast, all structures had to be able to withstand winds up to 155 mph as well as storm-water surge during a hurricane.

Unusual operating features

At low pipeline throughput volumes, the discharge pressure necessary for the station to meet the pipeline flowing conditions may be lower than required for proper operation of the gas-treating facilities.

Consequently, a backpressure regulator in the station's discharge piping may be used to ensure that the operating pressure through the gas-treating plant is within the design range.

Whenever station discharge-pressure requirements are greater than the minimum operating pressure, the backpressure regulator is bypassed and the station discharge flows through a full port, line-size valve.

Another use for the backpressure regulator in the station discharge is to increase the compressor head on cold ambient temperature days. Normally, gas-turbine emissions (NOx and CO2) are controlled by the unit's fuel-management system opening the gas turbine's bleed valves.

On cold days with low compressor loads, however, this procedure may be inadequate for emissions compliance. The backpressure regulator can be used to increase the load on the turbine, thus maintaining emissions compliance.

In the event of an upset in the gas-processing facilities, the station's discharge valve is closed and the off-specification gas will be recycled from the gas compressor's discharge back to the inlet of the gas-treating facilities for reprocessing.

Station control system

Station 100 was designed for unattended, remote operation via a supervisory control and data acquisition system using a microwave link from the station control panel (SCP) to the Williams Transco gas control center in Houston.

Operation, monitoring, and control of the station will normally be accomplished from the gas control center. The local station's control panel, however, is also fully capable of complete automatic control of the station facilities in a malfunction of the SCADA system using set points and commands last supplied by either the gas control center or locally input.

The control system uses 23 Allen Bradley programmable logic controllers 11 ControlLogix and 12 SLC 5/05. The PLCs are networked via two plant-wide redundant counter-rotating optical ethernet networks. Monitoring and control is accomplished through two redundant Wonderware HMI servers that communicate to redundant structured-query-language (SQL) servers for historical data logging.

Programming of the PLCs and station control panel was principally performed by Hinz Automation Inc., Minneapolis, with site integration by a consortium of parties. All servers are Compaq Proliant rack mount server-class machines.

Inter-server communications within the control room are accomplished via gigabit (1,000 Mb) ethernet and fast ethernet (100 Mb). The control console is a state-of-the-art Evans console utilizing eight 21-in. LCD flat panel monitors having 1600 x 1200 resolution to maximize display area for process control screens.

Allen-Bradley Flex I/O is used for marshalling the field end-device signals to the station control panel via a redundant counter rotating optical ControlNet.

The station networks are linked via redundant routers to Williams Cos.' intranet. This allows remote monitoring of Station Wonderware via Windows 2000 Terminal Services Client as well as station software maintenance of PLCs and servers. Any computer connected to Williams' network or worldwide internet using virtual private networking (VPN) can accomplish this.

Local unit control panels report to and allow operation of equipment from the station control panel. Operation of the station uses PLCs and microprocessors in local control panels and individual equipment modules. Equipment unit controls also include the capability for local control via the station's ethernet.

A total of four uninterruptible power supply (UPS) systems provide power to critical functions within the control system during the transition period when incoming electric power is lost and the standby generators are on-line.

The UPSs are connected to the station network and utilize simple network management protocol (SNMP) to allow monitoring of the status from any computer on the station network or Williams' intranet via Microsoft Internet Explorer.

The safety system of the station is enhanced by installation of three-color video cameras in the plant area capable of scanning the station yard. The cameras are controlled by two redundant video servers installed on the station network that allow for remote video monitoring of the video feed from any computer on Williams' intranet or worldwide internet using VPN.

Full pan tilt zoom (PTZ) control of each camera is available from the control console or remote computer. This allows operator viewing of all critical areas of the plant from the control room or remotely anywhere on Williams' intranet. The video servers record up to 60 days of video that can be reviewed and archived as needed.

Safety considerations

Design of the station included a three-tier safety shutdown system that provides protection required by any particular emergency situation within the requirements of the US Department of Transportation code. Station 100's emergency shutdown and blowdown system consists of the following types of shutdowns:

- Station emergency shutdown (ESD).

- Station emergency shutdown and blowdown (EBD).

- Unit emergency shutdown and blowdown (BEBD).

Station ESD applies to all equipment and systems within the station limits except certain critical service equipment required for personnel safety and equipment protection.

A station ESD causes a complete stop of all station operations by initiating emergency stops of operating equipment and isolating the facility from all external pipelines.

The station and equipment high-pressure piping remains pressurized. Emergency lighting, post lube-oil pumps, and 24-v (DC) powered station controls and equipment will not be deactivated by a station ESD.

Station EBD consists of the station ESD functions plus de-pressurization of all station piping and selected operating systems in the gas-treating facilities, de-energizing of electrical circuits, and initiation of safety sequences. Blowdown of the compressor station piping is accomplished by separate vent stacks on the station suction piping and station discharge piping. Gas is vented from the gas-treatment facilities through a flare at a controlled rate to prohibit damage to the equipment.

The station EBD system consists of separate ESD and EBD pilot-gas pressurized headers routed throughout the station. Loss of pressure in either header indicates an unsafe operating condition and the appropriate actions are initiated. Depressurization of the headers may only be initiated by manual actuation of valves at strategic locations or by an electrical pull-button in the station control room.

Station operations are returned to a normal operating state only after a manual reset of the emergency shutdown and blowdown system.

A unit BEBD causes an emergency stop of all equipment within the operating unit, isolation of the unit piping from the station piping, and depressurization of the equipment and piping depending on the type of equipment. The BEBD affects only the individual equipment unit and associated ancillary equipment. All other facility operations remain normal.

Fire and gas detectors are installed in the gas compressor buildings and propane refrigerant compressor building.

The fire-detection system for these buildings automatically trips the unit's emergency-stop logic. The gas-detection system will automatically cause the building's forced-ventilation system to start upon reaching the 20% lower explosive limit (LEL) and at 40% LEL to initiate a unit emergency stop, unit isolation, and blowdown.

Fire and gas detectors are also in the station yard but will alarm only and not cause the shutdown of any equipment. A voting logic will be included for all yard detectors.

Logic for the fire and gas detectors is performed in a dedicated fire and gas PLC. Separate fire and gas panels are provided for each compressor building, the gas-treating facilities, and the station control room. The fire and gas detector system will not automatically initiate a station ESD or EBD.

Shared risks

The project team recognized early that the project's fast-track schedule would not allow the traditional method of selecting a site-construction contractor.

Traditionally, major equipment and materials are procured, detail design drawings completed using vendor-supplied data, and proposals are requested from construction contractors.

Instead, Willbros recommended that site-construction proposals be based on a partially completed design, material delivery schedules, estimated work quantities, scheduled in-service date, and contractor's experience.

The bid proposals would provide unit prices for the estimated work quantities. The proposals allowed Gulfstream to evaluate the contractor's approach and its potential for successful completion.

Gulfstream negotiated a contract that allowed the owner and contractor to share the risks on the project and provide incentive to the contractor for on-time completion. The final contract was a fixed fee/reimbursable cost agreement.

Gulfstream awarded the contract to Harmony Corp., Baton Rouge. The fixed fee/reimbursable cost agreement allowed Gulfstream to advance the project critical path by proceeding with on-site construction while the design was being completed. The gas-treatment facility was supplied under a separate design, procure, and fabricate contract that was awarded to Pro-Quip Corp., Tulsa, a Linde Co. The site construction contractor was responsible for erecting the gas-treatment facility as the components, skids, and interconnecting piping were shipped to the site by Pro Quip and the facility's scope of work was incorporated into the bid proposals.

Gulfstream had the site construction contractor work from both the Willbros and the Pro Quip construction drawings.

Willbros provided all of the foundation designs, coordinated all of the interface points between the gas-treatment facility and the station, as well as oversaw the Pro Quip work to ensure there were no gaps in the design.

On May 23, 2002, FERC approved the Gulfstream Natural Gas System for operation ahead of the scheduled in-service date of June 1, 2002, established in 1999.

Acknowledgments

In developing this article, the author acknowledges the support from Gulfstream, in particular Paul Grosskopf of Duke Energy, and from Willbros Engineers Inc., in particular David Hairston, Tom Alexander, Ken Nicholas, Jack Wiser, Mark Biesemeyer, Mike O'Brien, Tom Roach, Chris Fletcher, and Don Moyer.

The author

Lannie McNeill is a senior project design engineer at Willbros Engineers Inc., Tulsa, with more than 27 years' experience at Willbros primarily in engineering design and project management of oil and gas pipeline facilities. For the past 12 years, he has specialized in the design of gas turbine-driven compressor unit additions and major capital expenditure projects in gas compressor stations. He served as the lead mechanical engineer for the design of Station 100 on the Gulfstream Pipeline Project. McNeill earned (1969) a mechanical engineering degree from Oklahoma State University, Stillwater.

Correction

Fig. 3 in "Fed data show solid 2001 for US pipeline companies, more gas capacity planned" (OGJ, Sept. 16, 2002, p. 52) contains an error in the "Offshore" chart. The correct portion for the labor component is 45.19%.