Mineralogy-based acid design restores sandstone productivity

The selection process of candidate wells for acidizing treatments in sandstones must identify relevant damage mechanisms and mineralogy-driven remediation options. A combination of production logging and geophysical analyses, coupled with reservoir simulation, is insufficient for selecting the candidate wells, as shown by results from wells in the South China Sea,

In these wells, sandstone formations with an average 20% carbonate content are not good candidates for treatments that include hydrofluoric (HF) acid because the acid may cause severe secondary and tertiary precipitation that can reduce productivity.

Treatments with a nonhydrofluric acid, however, proved effective for restoring productivity.

South China Sea oil fields

The XJG 1, XJG 2, and XJG 3 oil fields in the South China Sea are 130 km southeast of Hong Kong.1 Commercial oil production from the fields, discovered in 1984, started in 1994 after installation of two platforms.

The fields produce 26-40º gravity oil from unconsolidated sandstones with an average 25% porosity and permeability measured in darcies. The formation is prone to produce sand, and the typical initial wells included internal gravel packs inside 95/8-in. casing. Recent wells, however, are completed with expandable sand screens in an open hole, making water control difficult.

In the wells, downhole electric submersible pumps (ESPs) improve productivity and handle high water volumes.

The combination of highly permeable formation streaks and an active aquifer accelerates water breakthrough in perforated zones, increasing the field's average water cut. The fields currently produce at an 84% average water cut. Total oil production is about 85,000 b/d, while total fluid production is approaching the 550,000 b/d capacity of the surface treating and water-disposal facilities.

For controlling water, the operator routinely uses production logging to monitor the fluid contributed by each zone, while external packers and sliding side-door (SSD) valves isolate reservoir zones.

Closing the SSDs in the high water-cut zones controls water, but it is difficult to know the source of the water or the amount of remaining hydrocarbons in the zone.

If a well still produces hydrocarbons, the operator considers a well workover as premature even with many closed SSDs. Also the multiple external packers in the wellbore make workovers expensive and risky.

Acid treatments can improve zone productivity without the need for a workover, but the selection of acidizing candidates is complicated. Complicating factors include multiple producing zones and the fact that each zone is isolated with separate sand screens and SSDs.

The SSDs allow for easier control of high water-producing zones and for selecting zones for acidizing, but the SSDs also present challenges for covering the entire zone with acid.

Furthermore, production improvements must take into account the processing capacity bottleneck, so that zones acidized must be those that produce less water.

Once the operator corrects the fluid processing bottleneck, acid treatments also may be considered for zones that produce greater amounts of formation water.

XJG-3 field

The XJG-3 field has 24 wells, producing from multiple commingled zones. The wells have downhole ESPs, and a strong water drive affects production. Total produced water cut ranges from 80 to 90%.

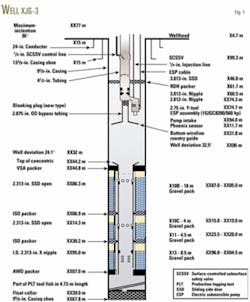

In the field, Well XB9, drilled in 1995, has four producing zones completed with gravel packs and SSDs (Fig. 1). In early 2001, the well was logged to determine the source for its high water production.

Zones X10C and X11 share the same gravel pack and SSD, so that production from these zones could not be differentiated, but the logs indicated that the zones produced at a 56% water cut, as expected.

The logs determined that Zone X10B contributed 74% of the total fluid production and had an 80% water-cut.

Zone X13, however, was underperforming and had an apparent total skin of 140.

The zone is at 10,150 ft measured depth (MD) and has a bottomhole static temperature (BHST) of 240° F., a 21% porosity, and an average 1,240 md permeability.

In February 2001, Zone X10B contributed 85% of the water and 49% of the oil, but the apparently damaged Zone X13 contributed only 2% of the total water production and 28% of the total oil production. In early 2001, the water cut from the X13 zone was about 14%.

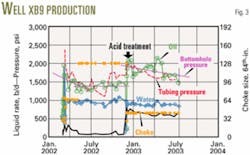

From early 1998 through mid-2001, production from the well gradually declined to 400 b/d from about 550 b/d (Fig. 2).

In early 2002, the operator increased the choke size on the well to 68/64-in. from 30/64-in. It was assumed that each zone produced at the same water cut and the proportion of production from each zone would remain the same, thereby essentially doubling the production from Zone 13.

But the increased drawdown rendered the assumption invalid.

The March 2002 increase in choke size restored production to 1,900 b/d, about the same as in the previous year, but water production doubled. Production continued to decline, and 2 months later, the operator increased the choke size to 128/64-in. Oil production stabilized at about 1,400 b/d, while water production remained nearly constant during the same period at about 9,000 b/d.

Evaluation of the data suggested that Zone X13 produced more water because of the higher drawdown. This raised the possibility of damage from fines-migration plugging the near wellbore or carbonate scaling.

By mid-2002, there was evidence that the oil contribution from Zone X13 had declined to about 90 b/d at a skin of 140.

Damage mechanisms

Damage during drilling may account for the underperformance of Zone X13. A possible damage mechanism was clay swelling caused by the invasion into the zone by water-based mud filtrate. Also during the completion, overbalanced perforating may have led to an ineffective perforation clean out. After the gravel pack, flow from the zone would neither remove the mud filtrate nor the perforation debris.

Determination of the composition of shale and sandstone formation composition was a useful starting place in identifying possible production damage mechanisms. But this information proved insufficient for identifying damage mechanisms and limitations for fluid selection.

In offset Well X2x, X-ray analysis showed the zone had an average mineralogy content of 48% quartz, 11% potassium-feldspar, 2% kaolinite, 15% illite-smectite, 11% calcium, and 7% dolomite. This was assumed also to be representative of the zone in Well XB9.

Kaolinite, a migrating clay, varied in abundance from 0 to 13%. Gravel-pack screens can control sand production, but do not address fines migration. Illite-smectite, a mixed layer clay, can swell in freshwater and brines less than 6% NaCl.2 3 Calcite and dolomite did not present a damage mechanism, although they did limit treatment options.

The mineralogy suggested fines migration and clay swelling as possible damage mechanisms for Zone X13.

Well XB9 did have a water analysis of the commingled water from the four zones. A scaling tendency calculation indicated a very slight barium sulfate scaling tendency, but this was not considered a likely damage mechanism.

A likely damage mechanism was the strong scaling tendency predicted for calcium carbonate at a pH of 6.8 and 240° F. The increased drawdown of the well in early 2002 may have triggered an increase in both water production and carbonate scaling.

The water analysis did not clarify the role of clay swelling in the reservoir. Smectite requires at least 6% NaCl to prevent swelling, and the analysis indicated the well produced water with about 3% NaCl.

The possibilities were that:

- The clays were swelled partially.

- The calcium in the water was preventing clay swelling.

- The illite-smectite clays were swollen but also were located in layers that did not affect production.

Mineralogy-driven options

Drilling damage, fines migration, clay swelling, and carbonate scaling were the four possible damage mechanisms affecting production from Zone X13.

Historically, the procedure was to select acid systems for attacking these problems based on the type of damage with minimal consideration to formation mineralogy. But this study made clear that the acid and rock interactions are more complex than previously thought and must be considered. These interactions readily explained why previous treatments did not improve, or may have further damaged, production.

While HF acidizing systems can remove drilling damage and fines migration, the carbonate content made HF acid a poor choice for this operation.

Acid could remove carbonate scale, but treatment must take into consideration the clay content and BHST in selecting the acid.

Clays are known to be unstable in hydrochloric (HCl) acid, depending on their composition and the temperature. Pumping strong HCl into a sandstone formation above the stability temperature of the clays can damage the matrix permeability during pumping.4

Also HCl and acetic acids, by themselves, will not remove fines-migration damage, and acetic acid used alone can cause clay swelling.5

The presence of illite-smectite indicates the possibility of clay swelling; therefore, the fluid selected was a mixture of acetic acid and ammonium chloride. This acid system could:

- Remove matrix carbonate and thereby remove drilling damage.

- Dissolve carbonate scale without destroying formation clays.

- Contact smectite clays without causing swelling.

Additional additives could reduce emulsion tendencies, improve water-wetting contact with the damage, and prevent corrosion of the tubulars.

The treatments also may have an issue with acid and oil compatibility. Acids can create sludges and emulsions when contacting oils.

HCl-based systems have good dissolving power but can require extra additives for maintaining good compatibility between the acid and oil.

Organic acids are milder and less likely to cause sludging problems when contacting black oils.

Treatment

The improved acid design addressed the issues raised by the review of previous acid treatments and the formation mineralogy.

The well apparently had scale buildup problems, and therefore the acidizing job included a small acid treatment to clean the tubing across the zone of interest. The procedure included closing the SSD and then pumping through a coiled tubing string 2,000 gal of 10% acetic acid for removing carbonate scale from the pipe. The treatment was circulated to surface with 13,000 gal of filtered seawater fortified with 3% KCl.

When the returns cleared, the next step included circulating into the wellbore with 12,000 gal of 5% ammonium chloride (NH4Cl). This left a fluid in the wellbore that would not cause clay swelling before or after ion exchange in the formation.

After the coiled tubing was pulled from the hole, the next step bullheaded the main treatment into the formation. The job included a preflush of 1,000 gal of 5% NH4Cl (with 500 scf/bbl of nitrogen) followed by the main treatment, consisting of 5,600 gal (120 gal/ft) of 10% acetic acid containing 5% NH4Cl, 0.2% penetrating surfactant, and 0.5% fines suspending-foaming agent.

This was followed by overdisplacement of the acid into the formation with 2,000 gal of 5% NH4Cl, and then displacement of the wellbore with 10,000 gal of filtered seawater fortified with 3% KCl.

These fluids contained at least 35,000-ppm chlorides and would not cause clay swelling before or after ion exchange in the matrix.

All fluids used included 500 scf/bbl of N2 to provide continual diversion and energy assist for fluid flowback.

The pump rate was 4 bbl/min at 2,500 psi during the first 80 min of bullheading the fluid into the formation. The tubing pressure quickly rose as the nitrified preflush reached the formation, reducing the pump rate to 2 bbl/min. The pressure broke back somewhat when the acid stage reached the formation, but the nitrified acid kept the treating pressure high.

It was necessary to reduce the pumping rate to 1.25 bbl/min to keep the tubing pressure below design criteria. The pressure decline during the 1.5-2 hr time period was caused in part by the lower injection rate and some damage removal.

The higher treating pressure provided by the nitrified fluids improved zonal coverage, or diversion, behind the SSD in the X13 zone. In addition, the 1.25-bbl/min pump rate gave nearly four times the contact time for the acid to react on the carbonate scales within the gravel pack and perforations, as compared to the 4 bbl/min pump rate.

The overflush stage reached the formation after 3 hr of pumping and showed a higher treating pressure. The higher nitrogen quality in the last stage probably caused this response.

Production results

The acid treatment immediately improved production to 600 b/d, even on a smaller 42/64-in. choke and at 700-psi wellhead pressure, which was 600 psi higher than during the previous 6 months.

The production increased without additional water production. The immediate post-acid treatment water cut for the well was 81%.

The process of assigning production contributions to various zones in a complex reservoir with complex completions was a challenge in this operation because production logging tools were unavailable.

Some assumptions provide some limiting cases.

The biggest challenge was in understanding the change in water cut that occurred in March 2002 when the well was drawn down harder. The increased water production, without a proportional increase in oil production, indicates that the water cut for each zone had increased.

On an historical basis, the water cut for Well XB9 had increased from 70% in February 2001 to 86% in March 2002. If the water in each zone increased proportionally and held constant to the same oil contribution, then the water cut for each zone had increased from 80%, 56%, and 14% to 91%, 77%, and 30% for X10B, X10C/X11, and X13, respectively.

But it is more likely that the water cut for X13 had increased to 50%. Using these modified water cuts and assuming that production for the top three zones after March 2002 was unchanged, one can estimate the decline in oil production associated with increasing damage in the X13 zone.

The analysis provides two possible limiting cases for the Zone X13 acid treatment in December 2002. Pretreatment production may have been the last value of 518 b/d in February 2001 or it may have been as low as 55 b/d as implied in November 2002.

In one case, the acid treatment provided a two-fold increase in production by removing old damage, probably from drilling damage and fines migration. In the other case, the acid treatment provided more than a ten-fold increase in production by removing recently caused damage, probably from carbonate scaling.

The decline slope for Well XB9 since the treatment suggests continued production-induced damage (Fig. 3). It is possible the damage mechanism continues to be carbonate scaling, though the decline slope is not as steep as in early 2002.

Acidizing can remove but not prevent carbonate scale. The well may require another acid treatment soon, but a scale inhibitor squeeze should follow the acid treatment.

The procedure should include returning the acid treatment to surface before performing the squeeze treatment so as to remove any released debris and diversion effects.

Acknowledgments

In addition to Halliburton and ConocoPhillips China Inc. for permission to present this work, thanks are also extended to Tuan Ma, Conoco- Phillips, principle reservoir engineer, for reviewing the paper and providing comments. The authors also acknowledge the Shell Group and their codeveloped STIM2001 software used during this project.

References

1. Luo D., et al., "Optimizing Oil Recovery of XJG Fields in South China Sea," Paper No. SPE 84861, International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Oct. 20-21, 2003.

2. Hower, W.F., "Influence of Clays on the Production of Hydrocarbons," Paper No. SPE 4785, AIME Symposium on Formation Damage Control, New Orleans, Feb. 7-8, 1974.

3. Gdanski, R., "Right KCl Mix Prevents Clay Swelling," American Oil and Gas Reporter, April 2000, pp. 131-33.

4. Gdanski, R., "A Model of HF Reactivity and Damage Removal," NIF 10th International Oil Field Chemicals Symposium, Fagernes, Norway, Feb. 28-Mar. 3, 1999.

5. Gdanski, R., "Fractional Pore Volume Acidizing Flow Experiments," Paper No. SPE 30100, European Formation Damage Symposium, The Hague, Netherlands, May 15-16, 1995.

Based on a presentation to the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, La., Feb. 18-20, 2004.

The authors

Zhizhuang Jiang (jason.jiang @conocophillips.com) is a production engineer for ConocoPhillips, Shekou, China. He graduated from Xi'an Petroleum Institute.

Donghong Luo (donghong.luo @conocophillips.com) is the reservoir manager for ConocoPhillips, China. He previous was a reservoir engineering project manager at China Offshore Oil Nanhai East Corp. Luo earned his MS in engineering from the Petroleum University Beijing. He is a member of SPE.

Zhiyun Deng (Zhiyun.Deng@ Conocophillips.com) is general manager of Xijiang operations for ConocoPhillips, Shekou, China. He previously was operation manager of CCLS (CNOOC China Ltd. Shenzhen Branch) and vice-president of the CACT operations group. Deng is a graduate of Guangzhou Petroleum College. He is a member of China Petroleum Institute and SPE.

King Kwee Chong (KK.Chong @Halliburton.com) is PSL country operations manager – Far East & South East Asia for Halliburton in Kuala Lumpur. He has 27 years of industry experience in hydraulic fracturing; acidizing; nitrogen service, coil tubing, and cementing. Chong has a BS in industrial computing from University of Southern Queensland, Australia. He is a member of SPE.

Rick Gdanski is a scientific advisor in the production-enhancement section at Halliburton's Duncan, Okla. technology center. His responsibilities include research, teaching, and treatment design in the areas of sandstone acidizing and carbonate acidizing. Gdanski holds a BS in chemistry from Southwestern Oklahoma State University and a PhD in physical organic chemistry from the University of Illinois.