Special Report: Sustainability reports address oil spills and GHG emissions

Safety improvements aimed at better protecting both the environment and employees were key topics for major oil companies that issued 2007 sustainability reports or corporate social responsibility reports.

The lengthy, nonfinancial disclosures focus on what the companies call responsible energy development while the world faces increasingly difficult energy choices and concerns about climate change.

In these reports, companies outlined both achievements and disappointments. Content of the reports vary considerably among companies and also among countries. The following summaries show the variety of information oil companies reported.

StatoilHydro: spill unacceptable

Statoil ASA and Hydro ASA formally merged as scheduled on Oct. 1, 2007, and the resulting company said its goal is “to remain a competitive and sustainable group.”

Noting “high ambitions in the environmental area,” StatoilHydro said a December 2007 oil spill into the Norwegian North Sea from the Statfjord A platform was unacceptable. It was the largest oil spill so far on the Norwegian continental shelf.

Some 27,500 bbl (4,400 cu m) of crude oil leaked from the Statfjord A platform while a shuttle tanker was loading from the platform. The company’s sustainability report said 2007 oil spills tallied 4,989 cu m total, up from 181 cu m in 2006.

A subsequent investigation showed the Statfjord oil spill did not cause any obvious harm to the environment. The investigation was carried out by Sintef, the Institute of Marine Research, StatoilHydro, and the Norwegian Institute for Nature Research. The spilled oil began disappearing 3 days later from the sea’s surface.

Norway’s Petroleum Safety Authority (PSA) released a report critical of StatoilHydro’s operations on the Statfjord A platform.

“An investigation reported serious weaknesses and recommended a number of technical, organizational, and management measures,” said StatoilHydro, noting that its goal is a robust, efficient response to oil spills despite harsh, cold conditions.

The company’s 2007 sustainable development report, entitled “Going North,” outlines efforts to expand its international presence. StatoilHydro entered the Canadian oil sands through the acquisition of North American Oil Sands Corp.

“The easily accessible resources are getting ever scarcer,” StatoilHydro said. “Our industry accordingly directed its gaze to the far north in the hunt for tomorrow’s oil and gas. That creates great opportunities, but also poses big demands for sustainable solutions.”

Internal postmerger work continues. StatoilHydro believes the in-house integration process will extend into 2009.

“First comes the design phase, where we describe the new standards we’re going to work to and the operations philosophy of the restructured organization,” Vice-Pres. Mereta Aasheim said. “That’s followed by planning the implementation, and finally by the actual implementation. This is a far-reaching job.”

Petrobras and biodiversity

Brazil’s Petroleo Brasileiro SA (Petrobras) created sustainable development guidelines for its exploration and production efforts in the Amazon. Scientists and regional agencies helped prepare the guidelines aimed at protecting the region’s biodiversity.

“Preserving the Amazon rainforest is a strategic priority for the company,” said Petrobras Chief Executive Officer Sergio Gabrielli. Last year, the company launched the Petrobras Center of Environmental Excellence in the Amazon.

Petrobras spent years negotiating a development plan and an environmental management plan for Ecuador’s Block 31, which includes territory in Ecuador’s Yasuni National Park, a UNESCO Biosphere Reserve (see map, OGJ, July 10, 1995, p. 32).

The Ecuadorian government recently announced that Petrobras agreed to transfer the block license to the state. Petrobras received the license in August 2004 but never started production. Environmental groups protested exploration and production in the park.

In September 2008, Ecuador officials announced an agreement with Petrobras to transfer the Block 31 license to the state and Petroecuador. Officials suggest Block 31 probably will be operated by Petroamazonas SA, a unit of Petroecuador.

Elsewhere in the Amazon, Petrobras created a nursery for seedlings of native rainforest species used to restore forest clearings and provided an orchidarium where orchid and bromeliad species are studied and preserved to be reintroduced to reforested areas.

The company said it confers with the International Union for the Conservation of Nature and Nature Resources regarding the IUCN red list of endangered species for information about species inhabiting areas where Petrobras has operations.

“Although it is not yet possible to list all endangered species found around company facilities, efforts are made to increase scientific learning in Brazil and to conserve endangered and other species and ecosystems,” Petrobras said in its Social and Environmental Report 2007.

The company said it also works with the Brazilian Ministry of the Environmental to help protect amphibians, reptiles, birds, and mammals. Last year, Petrobras joined the World Business Council for Sustainable Development, a business initiative focusing on sustainable development.

BP monitors safety

BP PLC’s executive team continues monitoring safety performance closely in the aftermath of the 2005 explosion at its Texas City, Tex., refinery.

“Since 1999 after the BP-Amoco merger, our safety performance has improved by approximately two-thirds, which over the past 2 years has been our best [record] ever,” BP Chief Executive Tony Hayward wrote in the BP Sustainability Report 2007.

The company’s ultimate goal is having no accidents, no harm to people, and no damage to the environment, said Hayward, who directs a group operations risk committee. A separate safety, ethics, and environmental assurance committee reports to BP’s board.

BP invested $6 billion in 2007 to review its assets and minimize the risk of major incidents. It also worked to strengthen its process safety management and to enhance the skills of operational staffers from executives to plant employees, the report said.

The company is making “substantial progress” in changing culture, becoming less bureaucratic, reducing complexity, and simplifying activities, concluded L. Duane Wilson, an independent expert hired to monitor BP’s progress on implementing recommendations to improve its process safety standards (OGJ, Sept. 8, 2008, p. 20).

Regarding midstream and upstream operational integrity, BP spent more than $250 million in Alaska to upgrade or replace pipelines, increase corrosion inspection and monitoring, conduct preventative maintenance and repairs, as well as to expand capacity and improve efficiency.

BP replaced sections of oil transit lines in Prudhoe Bay field during 2007-08, and the company expected to finish that work during 2008.

About 340 oil spill incidents involving 1 bbl or more were reported company-wide in 2007 compared with 417 incidents during 2006. The volume of oil spilled in 2007 was 1.05 million l. compared with 2.2 million l. in 2006, 4.3 million l. in 2005, and 5.7 million l. in 2004.

BP also seeks to influence HSE standards at joint ventures where it does not hold a controlling interest, particularly at the Russian JV, TNK-BP.

“In 2007, the board of TNK-BP established an HSE committee,” BP said. “Areas of focus where BP interacts with TNK-BP include occupational, process and driving safety and advice and technical support on TNK-BP’s environmental agenda.”

TNK-BP records its safety performance using international metrics aligned with the US Occupational Safety and Health Administration. TNK-BP is reports this through the International Association of Oil and Gas Producers, BP said.

ExxonMobil cuts emissions

In its 2007 Corporate Citizenship Report, ExxonMobil discussed its continuing efforts to reduce greenhouse gas (GHG) emissions in its operations and to develop new technologies that enable more-efficient energy use.

The company reported a 23% reduction during 2004-07 in combined emissions of volatile organic compounds, nitrogen oxides, and sulfur dioxide from operations. In 2007, ExxonMobil reported 141 million tonnes of GHG, down about 5 million tonnes from the previous year.

ExxonMobil conducts internal research and also works with universities and other companies to develop technologies aimed at cutting GHG emissions for the long term. Technologies include gasification, biofuels, and carbon capture and storage.

High environmental standards are a goal, particularly when operating in areas without local standards. ExxonMobil Development Co. developed standards for nitrogen oxides emissions, offshore drill cuttings discharges, and flare and venting reductions.

Reduction of hydrocarbon flaring is a priority.

ExxonMobil–a member of the World Bank’s Global Gas Flaring Reduction Partnership–flared 8.1 million tonnes total worldwide last year, up from 7.7 million tonnes in 2006.

“Our operations in Nigeria continue to be the largest source of flaring among our operations globally,” ExxonMobil said. “To eliminate routine gas flaring in Nigeria, we are investing more than $4 billion in gas utilization and commercialization projects.”

Downstream, ExxonMobil’s refineries reduced flaring by 15% in 2007. That reduction stemmed partially from construction of a new light hydrocarbons recovery unit at the 78,000 b/cd Altona refinery near Melbourne, Australia.

Shell promotes CCS

Royal Dutch Shell PLC is promoting carbon capture and storage (CCS) technology to reduce GHG emissions from the power sector and oil industry.

“It is an area where, with our engineering skills and knowledge of underground geology, we hope to make a big contribution to managing CO2,” Shell said on its web site. “We are encouraging governments to move fast to create the incentives and regulations needed to get CCS demonstration plants up and running.”

Shell said it’s determined to help build CCS capabilities in part because the company believes this technology will be important for managing CO2 emissions from Shell’s refineries, chemicals plants, and oil and gas production.

The major joined a broad-based coalition named the European Technology Platform for Zero Emission Fossil Fuel Power Plants (ZEP). ZEP wants to see CCS in commercial use by 2020.

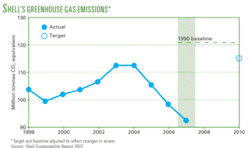

“There is no time to lose,” said the Shell Sustainability Report 2007. “Every year’s delay in the large-scale rollout of CCS adds more than 1 ppm to long-term global levels of CO2 in the atmosphere.” Shell executives urge governments to establish international policies to lower GHG emissions without distorting competition. For itself, Shell set a 2010 target to keep GHG emissions from operations at a level that is at least 5% below 1990 levels.

So far, Shell has reduced GHG emissions by nearly 25% compared with 1990 (see figure, p. 24).

Chevron analyzes projects

Chevron Corp. last year implemented its Environmental, Social, and Health Impact Assessment (ESHIA)–a process applied to new capital projects to identify, analyze, and enhance environmental, social, and health benefits.

Chevron’s Piceance basin natural gas project managers used the ESHIA to assess the project’s environmental footprint in western Colorado. Consequently, the project is using the latest technology in directional drilling rigs to drill multiple wells from one location. The development is on private land so no federal permits are needed and no environmental impact assessment is required.

Nevertheless, Chevron conducted a series of public stakeholder meetings throughout 2007. Chevron plans to develop up to 40,000 acres of natural gas reserves in the Piceance basin.

An ESHIA report outlines a management plan that incorporated social and environmental issues. For the Piceance basin, this resulted in moving a school playground away from a road used by trucks and putting a concrete safety barrier along school property.