Two-phase flowing material balance accurately models high WOR

Based on Lim, S., Muralidharan, M., Esmail, S., and McKone, S., “Improving Analytical Flowing Material Balance Workflow Considering Formation Water Production,” URTeC 3722261, Unconventional Resources Technology Conference, Houston, Tex., June 20-22, 2022.

Single-phase flowing material balance (FMB) typically overestimates fracture-stimulated reservoir volume (SRV) oil in place (OIP). To correct SRV-OIP for water saturation, Occidental Petroleum Corp. developed a two-phase transient model and applied it to Delaware basin (DB) production data. History matching showed that the two-phase model accurately matched SRV-OIP in DB wells with high water-oil ratio (WOR).

Multiphase model

Log-log plots of flow-differential pressure (q/DP) vs. time and Cartesian plots of DP/q vs. square-root of time identify when multi-fractured horizontal wells enter formation-transient linear flow as fluid flows from the formation towards fractures. In this flow regime, the log-log plot slope is -½, and the square-root of time plot yields a straight line. End of linear flow, when transient pressure from offsetting fractures interferes with each other, is identified by a change in slope on the log-log plot or by offset from the early-time straight line portion on the square-root of time plot. SRV hydrocarbons in place derive from the normalized rate at this transition time in a flowing material balance (FMB) q/DP vs. normalized cumulative production plot.

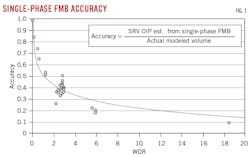

FMB is evaluated in either single or multiphase flow, with a pseudo-pressure approach used for multiphase analysis. Single phase typically overestimates original oil in place (OOIP). An integrated reservoir study correlating water production to predicted SRV volumes through numerical simulation of synthetic wells with typical Permian-well rock properties, PVT properties, pressures, and rates shows larger SRV-OIP than derived from single-phase FMB plots, especially for high WOR.

The single-phase model assumes all fluids are oil, however Permian formations contain relatively high mobile-water saturations. A larger tank is required for an undersaturated two-phase reservoir (above bubble point) to deliver the same amount of oil as from a single-phase reservoir subject to the same pressure drop with similar compressibility.

A two-phase transient model corrected for water saturation was applied to DB Wolfcamp A, 2nd Bone Spring, and 3rd Bone Spring production data. Median WOR ranged from 2-4 bw/bo during the first 3-6 month’s production to more than 10 bw/bo during subsequent production for some areas in Wolfcamp A.

The developed FMB equation combined the material balance equation with Darcy’s pseudo-steady state inflow equation. The original single-phase oil FMB equation assumed undersaturated conditions with no gas cap, no continuous water influx, and negligible water production. These assumptions are not correct for Permian wells and the equation was modified to include water production. Fracture water flowback is not included as most of it flows back during early-time production (within 30 days). After that, WOR stabilizes.

Equation 1 shows the original single-phase oil flow equation. Equation 2 shows the Occidental water-corrected FMB equation. Occidental’s paper includes detailed equation derivation.

The water-corrected FMB equation is like single-phase equations except for an additional 1+WOR/Boi term to account for formation-water production. WOR derives from stabilized formation-water production rates, after initial fracture-water flowback but before water encroachment from potential offset frac hits.

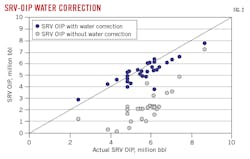

Occidental calculated SRV-OIP with the water-corrected model using the same synthetic dataset that revealed poor correlation between calculated SRV-OIP and actual formation volume using the single-phase model. The water-corrected model significantly improved predicted formation volumes (Fig. 2).

The model was validated with three fully developed DB sections using wells with similar spacing, landing strategies, and completion designs. WOR varied among the examples; Section A had lowest WOR (1.1 bw/bo), Section B had an average WOR (2.5 bw/bo) and Section C had highest WOR (4.8 bw/bo).

Rate transient analysis of pressure and rate data allowed derivation of SRV for each well. Fig. 3 shows 5-year total liquid production with single-phase and water-corrected model SRV estimates. The water-corrected model produced strong correlation between SRV prediction and total produced liquids without well bias whereas the single-phase model yielded little overall correlation and separate trends for each well.

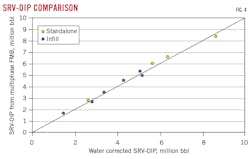

Multiphase FMB SRV-OIP calculated for ten randomly selected standalone and infill wells in DB were compared with the water-corrected model SRV-OIP. WOR was 1.2-3.0 bw/bo. Calculated volumes from both methods closely agreed (Fig. 4). The water-corrected SRV-OIP model is more practical to implement than the multiphase FMB model with pseudo-pressure and requires less engineering judgement to history match multiphase FMB. The water-corrected model required only two variables, WOR and Boi, which are readily obtainable from production data.

The model is also limited to reservoirs producing above bubble-point pressure during the linear-flow period. Wells in DB generally have a flat GOR profile before the end of linear flow, indicating that this assumption is broadly applicable in DB. For a volatile oil reservoir or tightly spaced development where early-time rising GOR is observed, additional adjustment may be needed to compensate for increasing compressibility under reservoir pressure decline.

About the Author

Alex Procyk

Upstream Editor

Alex Procyk is Upstream Editor at Oil & Gas Journal. He has also served as a principal technical professional at Halliburton and as a completion engineer at ConocoPhillips. He holds a BS in chemistry (1987) from Kent State University and a PhD in chemistry (1992) from Carnegie Mellon University. He is a member of the Society of Petroleum Engineers (SPE).