Construction costs erratic in first-half 2020

Pritesh Patel

IHS Markit

Houston

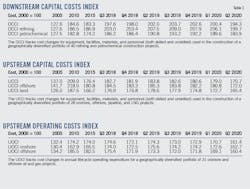

IHS Markit indices are proprietary measures of cost changes similar in concept to the Consumer Price Index (CPI) and draw upon proprietary IHS Markit tools to provide a benchmark for comparing construction costs around the world. Construction costs are tracked on a quarterly basis and then reported as an index value to show how upstream and downstream project cost have changed.

The base year is 2000 (2000=100). Therefore, an index of 203.7 indicates construction costs have increased 103.7% since the year 2000.

In first-half 2020, the IHS Markit Downstream Capital Costs Index (DCCI) decreased 4.1% from 202.6 in fourth-quarter 2019 to 194.3 in second-quarter 2020. The figure of 194 marks the lowest point since fourth-quarter 2017. Project activity has returned to a new normal. Construction projects that are financially viable have continued. Quarantine and social distancing practices have delayed completion timelines. Future construction projects have either been delayed or cancelled outright. Waning demand figures and issues securing capital have been the nail in the coffin for downstream projects. Material prices have come down in 2020 due to lower demand. The time to complete installations, however, has increased due to quarantine and social distancing measures. Vendors are coming under financial pressure due to the lack of future projects. To control cost upticks, operators have cut billable hours for subcontractors. Overtime hours have been cancelled and work weeks have been reduced to 35 hours. This will strain vendors financially; it is still unknown how many will be left standing in the end. Identifying vendors that are financially stable and have secure supply chains is critical. Allowing additional time during the contracting phase is wise. With limited capital available, selecting the most secure vendor is key.

The DCCI refining index decreased by 4% during the first half of 2020, from 207.9 in fourth-quarter 2019 to 199.7 in second-quarter 2020. A heavy turnaround season was observed in the second quarter, amplified by overfilling storage tanks and COVID-19 related weak demand. Pandemic related social distancing norms, staffing issues, and other restrictions forced actual maintenance work at refineries to extend. On the contrary, some refiners, such as Shell owned Pernis refinery (Netherlands)—Europe’s largest—preponed their maintenance. The third quarter is likely to be lower than normal amid rising demand, albeit fragmented. Equipment and labor are the two biggest line items in our refining cost estimates. Both markets experienced minimal declines during the quarter. Steel experienced the largest declines at 6% but its market weighting is 11.5%.

The DCCI petrochemical index decreased by 4.3% during first-half 2020. The petrochemical index experienced a greater decline in project costs due to higher weightings for equipment and steel. Equipment costs for petrochemical facilities declined 1.5% during first-quarter 2020. Projects in the Asia Pacific and Middle East represent a large bulk of the petrochemical project portfolio; during the quarter, equipment costs declined 1.8% and 1.3%, respectively, in those regions. Steel costs declined 5% during the quarter. Social distancing measures implemented to curb the spread of COVID-19 are the biggest concern for petrochemical projects in 2020. Project schedules are vulnerable if there is an outbreak at a construction site.

The IHS Markit Upstream Capital Costs Index (UCCI), which tracks the costs associated with the development of oil and gas fields, fell by 5.5% between the ends of fourth-quarter 2019 and second-quarter 2020, down to a value of 170.7. While some markets increased in the first quarter, all markets posted declines in the second quarter, driven either by low oil prices or the economic slowdown.

The largest declines were in the offshore rig market and engineering and project management (EPM), both declining 8%. For the offshore rig market, an oversupply of rigs coupled with falling demand led to the falling rates. Offshore rig contracts are being renegotiated, and several contracts have been suspended, canceled, or deferred. EPM charge-out rates are on the decline, but much of the decline was due to foreign exchange effects, only declining by 1-3% in local currency. The same can be said for the construction labor market, which declined by 4-6% in the US dollar index and just 1-2% in local currency. Bulk materials posted declines as well, global bulk material prices weakened in the second quarter as April was one of the worst months for economic growth in over a century. Demand for materials was weak as countries were under lockdown protocols and oil prices bottomed out.

The UCCI’s counterpart, the IHS Markit Upstream Operating Costs Index (UOCI), which measures the operating costs for those projects and their facilities, fell by 6.6 in first-half 2020, to an index value of 161.4. The decreases in UOCI have been driven by the oil price collapse and COVID-19 upheaval evident in industry actions. Operators have cut both capex and opex budgets and cancelled all but essential work, and service companies and some operators have been forced into survival mode with job losses already in the hundreds of thousands. No sector of the industry has been unaffected. The onshore UOCI fell by 6.6% in first-half 2020, and the offshore index also fell by 6.6%, propped up by the vessels indexes, which—already operating at such low day rates—had little room to fall. The impact of exposure to local currencies has been clear in second-quarter 2020, with a 6.6% depreciation overall across the portfolio; removing the impact of foreign exchange, the global portfolio fell by just 2%.

Capital and operating costs fell jointly during first-half 2020, however operating costs are forecasted to recover in 2021 while capital costs are not expected to recover to 2022, as spending in the industry is not expected to recover until the end of 2021 as uncertainly and low demand plague the industry.