Geosteering horizontal wells enhances production in Middle East field

Joint Operations, Saudi Arabian Texaco-Kuwait Oil Co., used geosteering to drill two wells in the South Umm Gudair (SUG) field for the first time in 2004.

Geosteering and horizontal well technology have been effectively used elsewhere to produce hydrocarbons from thin reservoirs to enhance recovery and restrict water-coning problems. Recent advancements in well placement by geosteering allow successful targeting of low-permeability reservoirs with great precision, resulting in more drainage exposure and reducing the long, transient production periods in the target pay zones.

In the SUG field, measurement while drilling (MWD), logging while drilling (LWD), and StrataSteer 3D services of Halliburton/Sperry-Sun were used. This article reviews the success of geosteering in two horizontal wells at the SUG field, targeting low permeability reservoirs, completed in July 2004.

Reservoir

The SUG field has produced from a Lower Cretaceous oolitic limestone reservoir with active water drive since 1966. The field development includes 63 active oil wells, of which 23 are horizontal wells. The lower zones are relatively homogeneous with permeability ranges from 300 to 400 md. They appear to be sufficiently drained over a period of time through vertical and horizontal wells.

The upper part of the reservoir is heterogeneous with lower permeability in the range of 50-150 md. This interval is relatively unswept and is now a target for new horizontal and horizontal sidetrack wells.

Joint Operations drilled two horizontal wells in the SUG field using geosteering techniques and used openhole logs of the pilot hole and offset wells to reference reservoir characteristics prior to drilling. Fig. 1 shows structural cross-sections depicting reservoir layers.

Inside the target layer is a possible barrier, evinced by a low porosity streak in the openhole logs. Modular dynamic tester (MDT) and repeat formation tester (RFT) pressure data from a few wells in the field show the presence of this low porosity zone. The asset management team believes this zone may impede, and possibly seal, vertical movement of water. Gross pay of this reservoir, above the barrier for geosteering purposes, is about 20 ft.

The main challenge of horizontal drilling in these two wells was to place the lateral section in the best porosity and stay above the barrier.

Geosteering model

The team optimized the predrill well plan using forward modeling after finalizing the actual well path, based on current structural and stratigraphic frameworks of the target area. Geosteering engineers loaded surface coordinates and deviation surveys of proposed and pilot offset wells, grid surfaces of reservoir layers, and open hole log data of pilot and offset wells into Sperry-Sun's StrataSteer 3D software to build the model.

This INSITE-based software integrated geological and petrophysical parameters around the target along the proposed well path, taking into account structural and stratigraphic variations and anisotropy with reference to the pilot and offset well log data. Before the geosteering program processed multiple data curves of pilot and offset wells, the data were despiked and filtered using log-squaring algorithms.

Petrophysical log signatures in horizontal and vertical wells for the same geologic unit are not identical because of different structural geometry with respect to the well bore. Adjusting the modeling algorithm took into account several parameters, including apparent dip, stratigraphic position, electrical anisotropy, polarization, and shoulder bed boundary. Iterated model adjustments produced the best fit of modeled log response, vs. actual log data. The final modeling generated the expected log response along the proposed well trajectory.

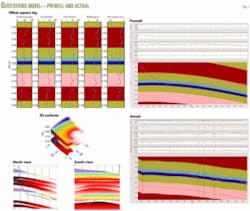

The prewell model (Fig. 2) shows various parameters used in the program, including a 3D view of grid surfaces, plan view of the proposed direction, pilot and offset well log data, and plot of the modelled log responses over the planned horizontal trajectory.

Drilling horizontal sections

The geosteering technique is a very dynamic, interactive, and intuitive process. Using mud pulse telemetry, the downhole tool continuously transmits real time data. The StrataSteer 3D program uses the data to steer the well into the reservoir following an optimized well path that avoids crossing undesired bed boundaries or fluid contacts. The program also analyzes reservoir properties in an attempt to maximize the productive interval.

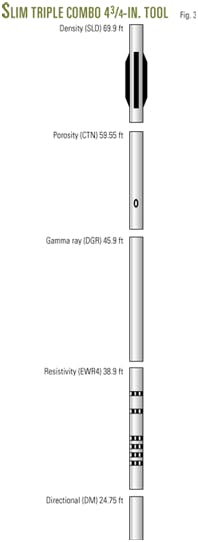

The downhole tools used in the MWD/LWD bottomhole assembly (BHA) to drill 61/8-in. horizontal sections in two wells include:

- Dual gamma ray (DGR).

- Electromagnetic wave resistivity (EWR4).

- Stabilized litho density (SLD).

- Compensated thermal neutron porosity (CTN).

- Direction module (DM).

Fig. 3 depicts the Slim Triple Combo 43/4-in. tool string used on these wells, including sensor offsets to bit.

Asset management teams chose a ±3 ft tolerance for the true vertical depth (TVD) window to place the lateral inside a reservoir about 20 ft thick. Geosteering guidelines based on prewell models, taking into account offset and pilot well logs, were combinations of values of gamma ray, resistivity, and neutron-density.

The operations team planned horizontal drain holes along the strike of the formation with negligible dip, but did not rule out structural and stratigraphical uncertainty. The characteristics of log data in the target reservoir were very distinct. The neutron-density porosity and gamma ray measurements were very sensitive and reflected immediate change with respect to variation from the planned model. Among all the log data, the team considered neutron-porosity to be the optimal geosteering guideline in order to stay within the ±3 ft window.

Correlating the real time logging sensor measurements determined the stratigraphic position. In order to derive the relative position of the well bore with respect to the reservoir layers, the well path generated by the directional survey tool was linked to the geological cross-section. After landing, the team compared the expected log response values, to the actual readings and found an apparent variation in the structural dip.

The drillers observed a tendency of the drilling assembly to build while rotating along some portion of the lateral hole. The driller corrected the drift by sliding the drilling assembly to maintain the well bore TVD.

The geosteering application program displayed data in a simple interpreted format that facilitated the speed and quality of real time decision-making. As the operator shifted the target points inside the geological model, the software reoriented the trajectory and dynamically recomputed the well plan. With real time data acquisition, the geosteering software performed quick adjustments inside the geological model to determine the structural and stratigraphic framework of the well path to remain within the optimum reservoir zone.

The dogleg limit to yield curvature constrained the projected well path for each target with reference to the BHA capable of achieving it. The interactive and dynamic functionality of the steering application allowed tracking the well path and making the appropriate changes, for optimum placement of the lateral in the desired sweet spot. Fig. 2 illustrates the actual model within StrataSteer 3D.

Operations observed some structural and stratigraphic variation from the modeled framework due to the minor dip changes along the target boreholes. In response, geosteering engineers applied real time geomodifications to align the borehole in the best porosity interval. Most of the lateral hole was drilled in rotary mode with minimal sliding to correct for the desired TVD. Both wells were drilled to the final target within the planned ±3 ft TVD window.

Based on resistivity, gamma ray, and neutron-density data, the laterals were optimally placed. Fig. 4 depicts the horizontal display of logs and the actual well paths.

Field test, results

After drilling was completed, the laterals were stimulated with acid to remove filter cake from the drilling fluid. Testing of Joint Operation's first geosteered horizontal well, in the low permeability reservoir of the SUG field, yielded very good results.

The first well produced 2,611 bo/d with 1.4% water cut. The second well produced 3,444 bo/d with 1.6% water cut. These results are very encouraging when compared to production of vertical wells in the same reservoir, which average 300-500 bo/d with about 50% water cut. The success of these two horizontal wells is due to the placement of the horizontal drain hole in the desired porosity/permeability interval using geosteering.

Excellent teamwork between Joint Operations and the Sperry-Sun personnel contributed to the successful geosteering for the two horizontal wells in South Umm Gudair field. The team achieved optimum lateral placement within the ±3 ft true vertical depth reservoir window, evidenced by resistivity, gamma ray, and neutron-density data. The improvement in well productivity of these two horizontal wells led to a development plan with additional horizontal drilling locations to recover unswept oil reserves from the low permeability reservoir section in the SUG field.

Acknowledgment

The authors thank the management of Joint Operations (Saudi Arabian Texaco-Kuwait Oil Co.) and Halliburton /Sperry-Sun for their permission to publish this article. We extend thanks to Khalid Al-Ali and David Barge of Joint Operations for supporting the need of geosteering and their suggestions in preparation of the article.

Reference

1. Ian C. Phillips, Martin D. Paulk, and Anne Constant. "Real Real-time Geosteering," SPE paper no. 65141, European Petroleum Conference, Paris, Oct. 24-25, 2000.

The Ratawi oolite is geologically equivalent to the Minagish oolite. In the joint operations field, in the Neutral Zone between Kuwait and Saudi Arabia, this formation has historically been called the Ratawi oolite. In Kuwait, Kuwait Oil Co. calls it the Minagish oolite.

The authors

Madan Jha ([email protected]) currently works as asset management team geologist for joint operations, Saudi Arabian Texaco-Kuwait Oil Co. Madan has 19 years' industry experience, the initial 14 with Oil India Ltd., formerly Burmah Oil Co. UK, as senior geologist, before joining KOC joint operations in 1999. He holds an MS degree in applied geology from the Indian Institute of Technology, IIT Roorkee. Jha is a member of the Petroleum Exploration Society of Australia and the Society of Petroleum Engineers.

Thanh Tran ([email protected]) currently works as asset management team leader and senior petroleum engineer for joint operations, Saudi Arabian Texaco-Kuwait Oil Co. Tran has 23 years' industry experience in production operations, reservoir management, horizontal drilling, and geosteering, in the US Gulf coast, Sumatra, and PNZ-Kuwait. Before joining Saudi Arabian Texaco, he worked for Getty Oil Co., Texaco Inc., and Caltex Petroleum Corp. Tran holds a BS degree in petroleum engineering from the University of Tulsa and is a member of the Society of Petroleum Engineers.

Don Hawkins ([email protected]) works as principal geosteering and LWD technical professional for Halliburton/Sperry-Sun. He has worked in the drilling technology industry for more than 28 years beginning in 1975 as a surface data-logging supervisor with Stratagraph Inc. Hawkins began his MWD/LWD career as a drilling dynamics and formation evaluation engineer with Teleco-Sonat, in 1986. In 1992, he joined Sperry-Sun Drilling Services. Prior to his current position, Hawkins worked as formation evaluation and MWD technical support advisor for Sperry-Sun. He is a member of the Society of Petroleum Engineers.