ICD-packer completion reduces water in China's Jidong oil field

Bailin Pei

China University of Petroleum

Beijing

Wu Long Bo Chen

Northwest Bureau of Sinopec

Urumqi, China

Songmei Zhang Jianwei Di

Anton Bailin Oilfield Technology Co. Ltd.

Beijing

Inflow control devices (ICDs) paired with oil-swellable packers often perform water control during well completions in unconsolidated reservoirs, but ICD-packer systems offer effective zonal isolation for only about 90 days.

Field studies demonstrate acceptable produced water volumes upon initial production of horizontal wells in China's Jidong oil field, but the water cut increased rapidly after 3 months while oil production decreased. Pressure-distribution analysis during laboratory simulations of water-control techniques in unconsolidated sands showed that pressure differences between the ends of a packer contributed to channeling.

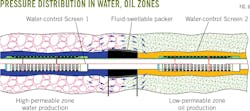

A horizontal well completed with an ICD-packer system provides several isolated flow units. Water entering a producing wellbore causes different flow pressures between oil and water units outside the ICD.

The differential pressure drives water into the adjacent oil unit through the unconsolidated sandstone outside the swellable packers. Unconsolidated sandstone will channel with time, rendering swellable packers inefficient for water control.

This article outlines how experimental simulation can forecast water breakthrough in a producing oil well.

Reservoir modeling can determine the critical pressure gradient that forms channeling in unconsolidated sand. Crucial differential pressure was evaluated to determine if ICDs and packers offer a feasible solution. A laboratory experiment resulted in a water-cut trend forecast that proved consistent with well-production data.

Jidong horizontal wells

Horizontal wells in various reservoir types commonly include ICD open-hole well completions and oil-swellable packers. Little long-term information exists on production after an ICD-packer completion.

Operators since 2004 have drilled horizontal wells in Jidong oil field in Hebei Province. Some wells were shut in within 1 year because of high water cuts.

Jidong operators started using ICD and oil-swellable packers in 2006, but water or gas early breakthrough remains a problem. Horizontal wells in homogeneous formations feature a heel-toe effect that causes unequal inflow, leading to water breakthrough at the heel. This occurs more commonly in heterogeneous reservoirs.

A horizontal well produces oil from stratum layers having different permeabilities (Fig 1). Viscosity differences between water and oil increase fluid influx unbalance, resulting in early water breakthrough.

ICDs can delay water breakthrough while oil-swellable packers create isolated zones and prevent fluid from flowing across them (Fig. 2). The ICD-packer combination can create a dependable fluid rate with a manageable pressure drop. The combination offsets tubing friction loss and other variables.

The onshore study well lies on Block G104-5 of Jidong oil field on the northeastern China coast. Jidong field covers 6,300 sq km, extending from the southern foot of Yanshan Mountain to the north to 1.5 km offshore into Bohai Bay.

Jidong's exploration and development area includes 3,600 sq km of land and 2,700 sq km of shallow sea. Block G104-5 mainly is composed of anticlinal and unconsolidated sandstone reservoirs.

The reservoir lithology consists primarily of fine and medium-grained sandstone, including part anisometric, pebbly sandstones and part sandy conglomerate. Quartz accounts for 41-56% of the reservoir. Feldspar is secondary.

Clay dominates cements in the reservoir. Carbonate is the subordinate cement mineral. Cement content is 5-20%. The reservoir has high porosity (~31%) and permeability (0.1-8,956 md), but also great heterogeneity.

The hydrocarbon viscosity of the reservoir is about 300 cp.

The operator started using the ICD-packers technique in 2009 to control water on two wells from Block G104-5. Results were very similar so this article only outlines details from one of those wells.

The swellable-packer isolating design addressed the well's 100-m horizontal production length. Three isolated production units were created using two oil-swellable packers.

The distance between each unit was about 30 m. Fig. 3 shows the well configuration with ICD-packers.

The ICD specification and model are the same in each flow unit. A 7-in. ICD screen (OD 210 mm) was installed in the 95⁄8-in. open bore hole (ID 241.33 mm). A 15.6-mm gap exists between the ICD screen and open hole.

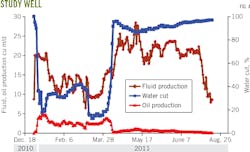

The study well initially showed relatively stable production. The water cut slowly rose to 40% from 20% before surging to 90% where it remained after 3 months (Fig. 4).

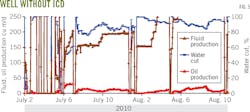

A separate well near the study well used traditional screen completion without an ICD. Fig. 5 shows its production performance. The water cut increased rapidly to more than 80% and remained high.

Two swellable packers divided the well bore into three isolated flow units from heel to toe. The first unit produced water with high permeability. The adjacent one produced oil with low permeability.

Pressure dropped greatly in the ICD of the water unit upon water breakthrough because flow accelerated. The oil-production unit exhibited a smaller pressure drop in its ICD.

The packer maintained differential pressure between the two units, with the pressure drop smaller than the production differential pressure (Fig. 6).

The pressure difference between the ends of the oil-swellable packer drove the water flow from the water unit to the oil unit. Water flow caused a collapse in the unconsolidated sand outside the packer to the annulus.

Channeling formed in the unconsolidated sand, making packer isolation inefficient. Once the isolation zones failed, water production increased quickly.

Pressure increased outside the oil unit's ICD screen. Formation pressure dropped, reducing oil production as the water cut accelerated.

Experiment logistics

Researchers designed this experiment to simulate differential pressure conditions that cause channeling in unconsolidated sands during oil production. The results can help an operator forecast pressure and decide if an ICD-packer combination should be used in a horizontal well.

The lab experimental device includes a water pump, packer, formation sand, and sand container. A 51⁄2-in. casing (ID 150 mm) served as a sand-filling tube to simulate the well hole.

The experiment's water-swellable packer (OD 102 mm, length 300 mm) models the performance of an actual well's 7-in. oil-swellable packer (OD 210 mm, length 6 m).

Retaining collars sealed the experimental packer ends. Fluid was allowed to flow through the unconsolidated sand when the swollen packer had a differential pressure.

The fluid used to trigger swelling differs in oil vs. water packers. Researchers used a water-swellable packer, which had no effect on the experiment's final results.

They filled the annulus between the packer and experimental well wall with sand from the field-study well. Researchers calculated particle-size distribution of formation sand in the experiment.

The experiment used sand particles with a 24-mm gap vs. the actual well's 15.6 mm. Water injection into the sand tube ensured the water-swellable packer filled and isolated sufficiently. The packer compacted surrounding sand tightly against the well wall.

A water pump provided high pressure to the inlet packer end, which simulated the well bore's differential pressure and flow. Two holes allowed sand and water to flow out of the experimental device, which modeled sand collapsing in the well bore.

Researchers sought to create the same 0.67-MPa/m pressure gradient as in the actual reservoir. The packer length in the actual well bore is 6 m, so the differential pressure between packer ends was 4 MPa.

Researchers concluded 0.2 MPa was the required differential pressure from the pump.

They placed a packer in the middle of the sand-filling tube. The gap between packer and sand-filling tube was filled and compacted with sand from the field-study well. Water filled the pores in the sand-filling tube.

The experimental device stood for 12 days to allow the water-swellable packer to isolate sufficiently. Researchers injected water from the inlet under 0.2-MPa pump pressure to model the flow process caused by the differential pressure between the two ends of the packer.

They observed and recorded the water and sand's outflow values. Initial inlet pressure was 0.2 MPa and the flow rate 0.1 l./min.

This status lasted 94 hr until the pressure suddenly dropped to 0 and the flow rate jumped to 12 l./min. Researchers found irregular flow channeling in the sand outside the packer upon opening the experimental device.

The pressure gradient of fluid flow in the unconsolidated sand was the same as with the experimental well bore. The time to form the channeling was directly proportional to the axial length of the unconsolidated sand outside of packer.

Fig. 8 shows the forecast and actual well water cuts. The water cut increased rapidly in a consistent, predictable trend in both the lab and the field.

The water cut rose suddenly in the experiment 2.5 months after initial production. The field study's water cut increased suddenly after 3 months, about 20% later than the forecast.

Water breakthrough in the actual well took longer than forecast because the sandstone in the field study increased flow resistance and delayed channeling. Sand compaction in the reservoir also was stronger than the experimental condition.

Acknowledgments

The authors thank Guojiang Feng, who conducted the experiment.

Bibliography

Al-Alyan, E.M. and Al-Mutairi, S.M., "Enhancing production performance of horizontal wells in naturally fractured carbonate reservoirs using Inflow Control Devices," Society of Petroleum Engineers Annual Technical Conference and Exhibition, Houston, Sept. 28-30, 2015.

El-Fattah, M.A., Gottumukkala, V., Ahmed, Sadah, A.A., Mohamed, T.I., and Nufaili, S.A., "Application of nozzle-based Inflow Control Devices (ICDs) in Al-Khafji field," International Petroleum Technology Conference, Beijing, Mar. 26-28, 2013.

Ellis, T., Erkal, A., Jokela, T., Kvernstuen, S., Leung, E., Moen, T., Porturas, F., Skillingstad, T., Vorkinn, P.B., and Raffn, A.N., "Inflow control devices-raising profiles," Schlumberger Ltd. Oilfield Review, Vol. 21, No. 4, Winter 2009.

Gomez, M., Anaya, A.F., Araujo, Y.E., Moreno, W.P., Bolanos, V., and Landaeta, L., "Passive Inflow Control Device (ICDs) application in horizontal well completions in the Rubiales area heavy-oil reservoir," SPE Heavy and Extra Heavy Oil Conference Latin America, Medellin, Colombia, Sept. 24-26, 2014.

Iqbal, F. and Iskandar, R., "Autonomous Inflow Control Device-A case study of first successful field trial in GCC for water conformance," Abu Dhabi International Petroleum Exhibition and Conference, Nov. 9-12, 2015.

Least, B., Greci, S., Konopczynski, M., and Thornton, K., "Inflow Control Devices improve production in heavy oil wells," SPE Middle East Intelligent Energy Conference and Exhibition, Dubai, Oct. 28-30, 2013.

Madan, M.A., and Aramco, S., "Milestones, Lessons Learned and Best Practices in the designing, deployment and installation of ICDs in Saudi Arabia," SPE Middle East Intelligent Oil & Gas Conference & Exhibition, Abu Dhabi, Sept. 15-16, 2015.

Madsen, T., "The Troll Oil Development: 1 billion barrels of oil reserves created through advanced well technology," World Petroleum Congress, Beijing, Oct. 12-17, 1997.

Youl, K.S., Harkomoyo, Suhana, W., Regulacion, R., and Jorgensen, T., "Passive Inflow Control Device and swellable packers control water production in fractured carbonate reservoir: a comparison with slotted linear completion," SPE/IADC Drilling Conference and Exhibition, Amsterdam, Mar. 1-3, 2011.

Zorbalas, K.I., Alyateem, K.S., and Elfattah, M.A., "Utilizing production logging measurement model matching to improve Inflow Control Device (ICD) completion design in offshore horizontal wells," SPE Annual Technical Conference and Exhibition, New Orleans, Sept. 30-Oct. 2, 2013.

The authors

Bailin Pei ([email protected] ) is an associate professor in the Petroleum Engineering Department at China University of Petroleum in Beijing. He holds a BS and MS in petroleum engineering from Southwest Petroleum University and a PhD in hydromechanics from the University of Science and Technology of China, Hefei. His research covers horizontal well water control, sand prevention, and inflow control devices.

Wu Long ([email protected]) is a senior petroleum engineer at Northwest Bureau of Sinopec. He graduated from China University of Petroleum in Shandong with an MS in geoscience. His research focuses on well completion and oil testing.

Bo Chen ([email protected]) is a senior reservoir engineer working in Sinopec's Northwest Bureau. He graduated from China University of Petroleum in Shandong with a BS (1993) in reservoir engineering. He specializes in field development and management.

Songmei Zhang ([email protected]) is a senior reservoir engineer at Anton Bailin Oilfield Technology specializing in water-control issues and sand prevention. Zhang graduated from China University of Petroleum in Beijing with an MS (2004) in petroleum engineering.

Jianwei Di ([email protected]) is a petroleum engineer with Anton Bailin Oilfield Technology. He specializes in reservoir characterization in tight formations and water control in horizontal wells. He holds a BS (2012) from China University of Petroleum in Beijing and an MS (2015) in petroleum engineering from the University of Calgary.