Seismic stimulation advances EOR technology

Bill Wooden

Applied Seismic Research Corp.

McKinney, Tex.

Sergey Kostrov

Applied Seismic Research Corp.

Frisco, Tex.

Seismic stimulation can arrest oil production decline rates in mature fields. The method has proved effective on diatomite, sandstone, and carbonate reservoirs. It holds promise as an alternative to refracturing in shale plays.

Operators frequently use gas injection, chemical injection, and thermal techniques for enhanced oil recovery (EOR). But these methods, including waterflooding, often prove too costly for smaller fields and ineffective in highly heterogeneous reservoirs.

Seismic stimulation for EOR works best in reservoirs featuring barriers to flow, creating pockets of bypassed oil. The immobile oil droplets are dislodged when downhole elastic waves propagate horizontally and vertically.

Los Alamos Laboratory studies found a pressure change as small as 0.01 psi can move an oil droplet.1 Shockwaves exit the stimulation tool at a wavefront pressure-amplitude of 3,500 psig. The waves travel at 1.5 miles/sec, reaching distances of 1.5 miles in carbonates and more than 1 mile in sandstones.

Seismic stimulation is unique compared with other EOR methods because the created elastic waves have no barriers, either in the vertical or horizontal plane.

Fault blocks, stratification, and changes in phase do not stop the stimulation as they would conventional, fluid-based EOR methods. A single seismic tool can stimulate large areas of a field that is either highly faulted or contains a series of pay zones.

This article examines how operators have used seismic stimulation for EOR in various settings.

Seismic stimulation

Reports of low-frequency, high-energy elastic waves mobilizing oil first emerged in the early 1950s when earthquakes were shown to increase production by up to 45%. The first manmade low-frequency, high-energy oil mobilization used Russian surface vibroseis stimulation.

Russian researchers discussed cyclic application of elastic waves as yielding optimal results and how application of elastic waves at various frequencies enhanced results.2-3-4

A conventional pumping unit powered the tool used in this study, which crews can install in abandoned wells at 700-10,000-ft depths.

Tool transport occurs in a 1 × 2 × 25-ft container, holding three preassembled sections. Joining the sections on location takes about 2 hr. Tool operation requires no major maintenance.

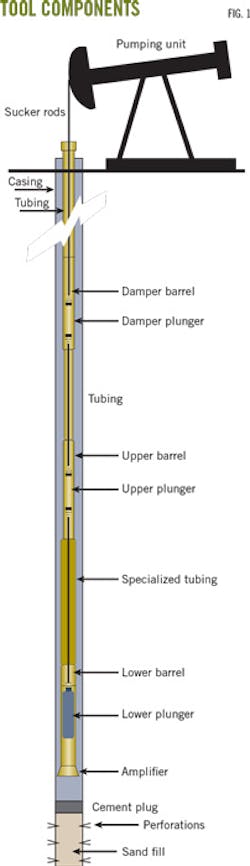

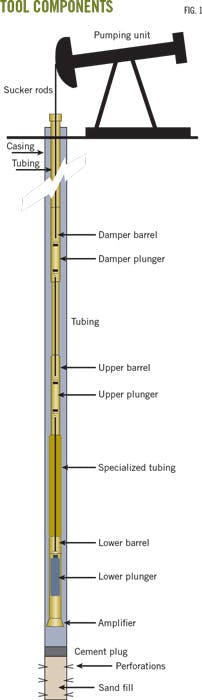

Fig. 1 shows the tool's components. Sand fill is in the well from its bottom to above perforations. Above the sand fill, a cement plug stops gas from entering the wellbore and tool.

Gas in the tool's compression chamber prevents creation of elastic waves. The tool is installed into the wellbore, connected to the rod string, and then to a pumping unit.

The pumping unit drives movement of three plungers within the tool in unison. The lowest plunger contains a traveling valve to bring in fluids. When the plunger reaches the top of its stroke, it exits the lower barrel to release highly compressed fluids, creating the shockwaves.

Fluids, compressed between the lower plunger and the middle plunger, are released in milliseconds. Specialized tubing acts as a compression chamber. The upper assembly acts as a damper to decelerate the upward velocity the system experiences on firing.

The damper maintains a minimum 2,500-lb load on the pumping unit to prevent zero loading.5

The process repeats itself as water is drawn into the tool and released. Seismic stimulation has zero environmental impact. The tool releases 2 gal of fluids and has no hydraulic connection to the reservoir. Only the sound of the pumping unit is heard at the surface. The shockwaves' momentum will not damage the cement bond or wellbore integrity.

Seismic stimulation does not work for all reservoirs. It works best in reservoirs with barriers to flow in the horizontal or vertical plane.

The tool-created elastic waves mobilize the lightest phase first, resulting in less water production and more oil production in a water-oil system. The presence of gas attenuates the waves' amplitude, making them less effective and limiting coverage.

The technology is best applied to fields having gas-oil ratios of less than 2,000 scf/bbl. Thick oil is less inclined to move regardless of the elastic wave strength.

Field trials showed that stimulation is unlikely for oil having gravity lower than 14° API. There is no depth limit, but deeper wells have increased rod stretch and require a larger pumping unit.

Permian basin

Carbonates respond to seismic stimulation with a discrete change in decline for as long as the method is applied. The Permian basin's San Andres, Clearfork, and Glorietta fields have all been good candidates.

Fig. 2 shows seismic stimulation results for a Permian basin North Robinson Clearfork carbonate in Gaines County, Tex. Energen Resources owns the field and has ongoing stimulations in several fields, including a San Andres formation.6

The stimulation affected wells within a radius of 1.25-miles. Decline before stimulation was 21%. It dropped to 10% with seismic stimulation, resulting in an average 60% increase in oil production.

Seismic stimulation is certified by the Texas Railroad Commission as an official EOR process, granting Texas operators a 50% severance tax reduction for 10 years.

Abraxas Petroleum Corp. used seismic stimulation to enhance oil production from a carbonate on its Bishop-Huddleston lease in West Texas (OGJ, Dec. 5, 2011, p. 86).

Response tends to be similar in unconsolidated sandstones as in carbonates. Fig. 3 shows results from a field in Egypt, which experienced nearly 40% increased oil production after seismic stimulation.

Seismic stimulation can be used in different types of formations (Table 1). Increased oil production after stimulation compares favorably with historic trends. All fields' stimulation represents total response of multiple wells within the radius of affection.

Stimulation also works across barriers. The method was helpful in an unconsolidated sandstone field in North Africa that involved a highly layered system. Producing horizons were all squeezed except the target zone, creating a good configuration to explore cross-layer stimulation, with the elastic waves exiting only the bottom set of perforations.

The stimulation resulted in:

• Total production increase of 1,200 b/d.

• Decreased water cuts.

• All wells except one showing significantly increased oil production.

Tubing pump problems during stimulation prevented increased production from Well 112-94. Overall results demonstrate that seismic stimulation works across flow barriers.

Fracturing

Industry's use of extensive hydraulic fracturing and long horizontal wells in US shale plays created a massive network of microperm fractures that adsorb, trap, hold, and otherwise fail to release water and unbroken gel.7

Seismic stimulation helps break down a gelling agent in fracturing fluid, release water, and open pore throats to flow, as well as enhancing already existing flow.

Unconventional oil production can create an extremely rapid shift in oil's relative phase-permeability when pressure drops at the wellbore, resulting in gas coming out of solution exceptionally quickly.

This is often a local phenomenon extending only a few feet into the reservoir above bubble-point. Large oil reserves could be just feet away from the wellbore and seismic stimulation will produce a good response in such cases.

Seismic stimulation also eliminates the need to repeat hydraulic fracturing, greatly improving shale-field economics.

High-energy elastic waves applied during fracturing will increase fracture propagation, accelerate gel breakdown, and boost recovery of fracturing fluids. This enhances oil recovery and potentially decreases the amount of fluids and gels left behind, lessening the induced-stress fields created by fracturing.

Two major operators plan seismic stimulation pilots to their shale fields once oil and gas prices recover. Production from exceptionally low-permeability fields that cannot be waterflooded falls off precipitously. Horizontal wells often are drilled in these fields, but even horizontal-well production plummets after initial results.

Multi-stage fracturing significantly improves initial production rates and extends drainage areas. Refracturing often renews production rates, but is also prohibitively expensive at current oil prices.

Seismic stimulation coupled with long horizontal wells and well-placed perforations might help eliminate both initial fracturing and refracturing in low-permeabililty fields. Operators could save thousands of dollars by eliminating fracturing, potentially altering field economics.

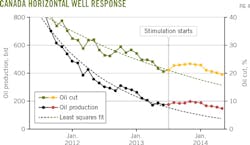

EOG Resources Inc.'s Waskada field in Canada featured a predominantly shale formation with some sand. Permeability tended to be significantly less than 0.1 md. Vertical wells were marginally productive. Horizontal-well production showed a rapid falloff.

A small tool available in a 4½-in. casing and having about 20% the power of the standard tool for 7-in. casing or larger, increased oil cut by 30% and oil production by 90% (Fig. 4).

Brownfield revitalization

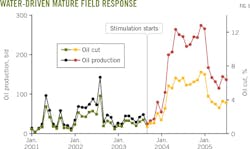

Water production can eclipse oil production in mature fields, making them unviable. A strong water-drive exists in Occidental Petroleum's Elk Hills field, coming down the fault lines to oil-bearing areas in the field's southwestern portion.

Oxy slowed encroachment by adding dewatering wells and producing them at extremely high rates. This provided an opportunity to study seismic stimulation in revitalizing brownfield reservoirs.

After installing the tool in an abandoned well central to the watered-out area of the front, the study monitored six dewatering wells, some running across fault blocks, for changes in oil cut and oil production. The furthest-most dewatering well was 1 mile from the seismic stimulation well. Fig. 5 shows the six dewatering wells' response. Initial response was negligible, making it appear that the watered-out region would not respond. Other areas of the same field had experienced early success with non-watered out wells. The reservoir was highly faulted, unconsolidated sand that held considerable bypassed oil.

Both oil cut and oil production began to improve during the third month of stimulation, the latter reaching 240 b/d from 35 b/d for the six monitored wells. Fluid production remained the same at around 3,500 b/d.

Oil cut increased from less than 1% to more than 7%. Both oil production and oil cut immediately dropped when stimulation stopped, although production and oil cut levels stayed higher than before stimulation, indicating new oil was mobilized.

References

1. Roberts, P.M., Sharma, A., Uddameri, V., Monagle, M., Dale, D.E., and Steck, L.K., "Enhanced DNAPL Transport in a Sand Core during Dynamic Stress Stimulation," Environmental Engineering Science, Vol. 18, No. 2, July 6, 2004, pp. 67-79.

2. Kurlenya, M.V. and Sergyukov, S.V., "Reaction of Fluids of an Oil Producing Stratum to the Low Intensity Vibro-Seismic Action," Journal of Mining Science, Vol. 35, No. 2, April 1999, pp. 113-19.

3. Nikolavevskiy, V.N., "Mechanism of Vibroaction for Oil Recovery from Reservoir and Domain Frequencies," Transactions (Koklady), USSR Academy of Sciences, Vol. 307, No. 3, 1989, pp. 570-55.

4. Nikolaevskiy, V.N., Lopukhov G.P., Yizhu, L., Economides, M.J., "Residual Oil Reservoir Recovery with Seismic Vibrations," SPE Production and Facilities, No. 5, May 1996, pp. 89-96.

5. Kostrov, S.A. and Wooden, W.O., "Method and Apparatus for Dampening Shock Waves in the Borehole of cont'd from pg. 51 Wells," US Patent No. 7,980,301, July 19, 2011.

6. Adams, R. and Wooden, W.O., "Seismic Stimulation," Permian Basin Oil and Gas Magazine, (PBOG) May 2016, p. 18.

7. Kostrov, S.A. and Wooden, W.O., "Method and Apparatus for Enhancement of Fracture Fluid Clean-up with Periodic Shock Waves," US Patent No. 8,684,076, Apr. 1, 2014.

The authors

William O. Wooden ([email protected]) is vice-president of Applied Seismic Research in McKinney, Tex. He has a background in sales and marketing of emerging technology. Wooden has BS degrees in math, chemistry (1977), and petroleum engineering (1980) from the University of Oklahoma.

Sergey A. Kostrov is Applied Seismic Research technical director in Frisco, Tex. He has been involved with theoretical and experimental investigations into the effect of elastic waves on mass-transfer processes in multiphase media. Kostrov holds an MS in mechanics of high-speed processes (1979) from Moscow State Technical University and a PhD in fluid mechanics (1982) from the Mechanical Research Institute of the Russian Academy of Sciences, Moscow.