CO2 use could boost Egypt's Western Desert oil recovery

Mahmoud Abu El Ela

Helmy Sayyouh

El Sayed El-Tayeb

Cairo University

Egypt

The main objective of this study was to develop a strategy that maximizes use of CO2 emissions from the Egyptian Western Desert. The study evaluates ways to capture these emissions for enhanced oil recovery (EOR) and assesses the applicability of CO2 injection in candidate fields.

Egypt has a single successful thermal EOR project, but no operator has tried even a pilot to test the feasibility and economics of CO2 miscible injection, which is the most widely applied EOR process worldwide (OGJ, Oct. 1, 2012, p. 84; Apr. 2, 2012, p. 57).1

The authors of this article, members of the Petroleum and Petrochemical Consultation Group, are trying to push a CO2 pilot in Egypt. They have discussed the concept with the last two ministers of petroleum and chairmen of Egyptian General Petroleum Corp. (EGPC), all of whom expressed support.

The political situation in Egypt during the last 3 years, however, has made it necessary to present the information to new officials.

Egypt's oil consumption exceeds its production, and reserves replacement has declined steadily the last few decades, shifting much of the focus to redeveloping and improving oil recovery from existing oil reservoirs.

Concept

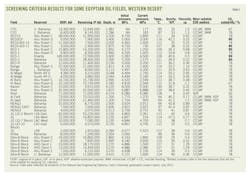

The first activity in this project was to screen 37 reservoirs to identify those most suitable for CO2 injection. The screening was carried out with specialized software (EOR Graphical User Interface-EORgui). Results of the screening indicated five reservoirs as candidates.

These lie in three Badr El-Din Petroleum Co. (Bapetco) oil fields: the Abu Roash G formation in Badr El Din (BED) 3C9 field, the Abu Roash C formation in BED 3-6/3-11 field, and Abu Roash C, Kharita, and Bahariya formations in BED 1 field.

The results indicate 76.2 billion std. cu ft (bscf) of CO2 to be required for injection. Injection of CO2 is expected to increase the incremental oil recovery by 7.62 million stock-tank bbl (stb), or 10% of the original oil in place (OOIP).

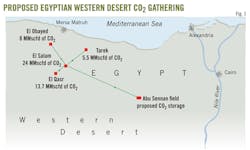

The study clarifies that the main sources of CO2 in the Western Desert are gas processing plants. Currently, 51.2 MMscfd of CO2-rich gas (about 70% CO2) can be recovered as byproduct from four main gas processing plants: Obayed, El Salam, Tarek, and El Qasr.

The CO2-rich gas streams can be gathered from the four plants to a central point in the El Salam area, then transported via 130-mile, 16-in. pipeline to Abu Sennan field to be stored in order to fulfill the EOR project's needs (Fig. 1).

This project can contribute to the improvement of Egyptian security of supply by increasing oil production and assisting in the reduction of greenhouse emissions.

Candidate oil reservoirs

Egypt's Western Desert is one of the country's largest oil producing areas. It is being developed with new discoveries that include some of the largest producing oil and gas fields in Egypt.

The main exploration and production operating companies in the Western Desert are Khalda Petroleum Co., a joint venture of Apache Corp. and Egyptian General Petroleum Corp.; Badr El Din Petroleum Co., a joint venture between Shell Egypt NV and EGPC; General Petroleum Co. (GPC) of Egypt; Agiba Petroleum Co., a joint venture between IEOC BV and EGPC; and Qarun Petroleum Co., another Apache-EGPC JV.

Recent production rates from the Western Desert are about 305,000 b/d of oil and 1.4 bscfd of gas.

The main Western Desert producing formations are Abu Roash C, Abu Roash D, and Bahariya. Abu Roash C and Bahariya are mainly sandstone, and Abu Roash D is mainly limestone.

In the current work, 24 oil fields containing 37 depleted reservoirs were selected for study. The depths of the studied reservoirs range between 900 m and 3,400 m. The initial reservoir pressure range is 1,750-5,000 psi; however, the current reservoir pressure range is 1,250-3,500 psi. Reservoir temperatures are 92-127° F. The oil is 35-40° gravity. Table 1 summarizes the main data of the selected oil reservoirs.2

Screening of the fields was carried out with specialized software (EOR Graphical User Interface – EORgui). Through the use of the EORgui software, the oil fields and reservoirs were screened and the potential of applying CO2 techniques was identified.

Table 1 presents the results of the preliminary screening for the studied reservoirs. The data indicate that the most appropriate EOR methods for the studied oil fields appear to be CO2 injection, immiscible gas injection, and alkaline-surfactant-polymer/polymer-surfactant injection.

Based on the history of successful EOR project results, CO2 miscible flooding seems to be the most appropriate method, and results indicate that the five reservoirs in the three fields are the most suitable for applying it (these reservoirs having a better match percentage with respect to the screening criteria).

Experience from worldwide operations has demonstrated that use of CO2-EOR can increase oil recovery by 5-15% beyond what is achievable from conventional recovery methods (OGJ, July 13, 1981, p. 43).3-6 The exact increased recovery fraction depends on the injection method used and the characteristics of each reservoir and its crude oil. Therefore, injection of CO2 to the selected reservoirs is likely to increase incremental oil recovery by an average of 7.62 million bbl, or 10% of OOIP (Table 2).

The total CO2 required for injection is expected to be 76.2 bscf, considering that 10 Mcf of oil of solvent is required for each barrel oil produced.6 7

The classification of fields as potentially being suited to miscible or immiscible CO2 displacement is very preliminary. More detailed field evaluation would be required for a more definitive assessment of the most appropriate technique to be deployed in a specific field.

CO2 sources, pipelines, storage

Table 3 shows the main characteristics of the gas processing plants that represent the main source of CO2 in the Western Desert. Together the plants discharge about 51.2 MMscfd of CO2-rich gas (70% CO2).

The study is extended to determine the optimum design considerations of the CO2 network that connects different CO2 source plants to the sites of storage and utilization.

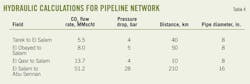

The available CO2 is initially planned to be gathered in the El Salam area. Then it is to be transported to Abu Sennan field for storage in order to fulfill the needs of the CO2 EOR projects (Fig. 1). Table 4 presents the results of the hydraulic calculations for the pipeline network.

The pipelines would be protected against corrosion by insulating joints, internal coating, and corrosion inhibitors. The doses and the type of corrosion inhibitors should be identified by a chemical treatment company during the detailed engineering phase

The designs and hydraulic calculations are to be carried out with several constraints. These include maintaining reasonable velocity in the pipelines, maintaining reasonable pressure drop across the pipelines, avoiding hydrate formation, and optimizing pipeline size to reduce project cost.

The shortest possible route would be followed to minimize the pipeline length, compression requirements, and the number of crossings, taking into account construction accessibility.

The pipelines are to be buried for security, piggable, and fitted with external coating and cathodic protection. Tie-in points are recommended every 20 km to accommodate future expansion from other sources.

The ability to store CO2 in a depleted reservoir in the Western Desert is also studied. The general requirements for the geological storage of CO2 include the following:

• Storage capacity is large enough.

• The storage reservoir has sealing layers top and bottom.

• The reservoir has adequate geological characteristics such as porosity, thickness, and permeability.

The study indicates that Abu Sennan field, which belongs to GPC, is the best option for CO2 storage in the Western Desert. The field includes three depleted reservoirs: Khoman, Abu Roash B, and Bahariya. Table 5 presents the main characteristics of the three Abu Sennan reservoirs.

Technical considerations, recommendations

The most critical parameter with respect to miscible CO2 flooding is the minimum miscibility pressure (MMP). The MMP is required so that CO2 becomes fully miscible with oil.

The MMP depends on the composition of crude oil, the purity of CO2, and reservoir pressure and temperature. Hence, a miscible CO2-dispacement technique can only be implemented when CO2 can be injected at a pressure higher than the MMP, which in turn must be lower than the reservoir fracture pressure.

Preferably, the injection pressure at the start of a CO2 flood should be at least 14 bar above MMP to achieve miscibility of CO2 and reservoir oil. This means that the ratio between reservoir pressure and minimum miscible pressure (P/MMP) normally should be greater than 1.0, but CO2 flood EOR is still possible for P/MMP greater than 0.9.8

Because of the uncertainties of both calculation of MMP and measured pressure data, reservoirs with P/MMP greater than 0.9 are regarded as suitable for CO2 floods by this screening if the reservoir pressure is lower than the original reservoir pressure at the start of CO2 injection. The MMP can today be measured experimentally or predicted with empirical equations and thermodynamic modeling with good accuracy (OGJ, Jan. 7, 2013, p. 74).

The utilization factors of solvent range between 6 and 10 Mcf/incremental barrel of oil recovered.6 7

Data from 10 miscible displacement projects in the Texas-New Mexico Permian basin indicate that the net injection of CO2 into an oil field (i.e. the difference between total CO2 injection and the recycled CO2) is on average 164 cu m/bbl (6,000 cu ft) of incremental oil (about equivalent to 330 kg/bbl). This value has shown to vary between 270 kg/bbl in Rocky Mountain projects to 400 kg/bbl in the US Midwest.

On average, oil recovery has been 10.9% of original oil in place in the Permian basin.13 The net volume of CO2 injected is 10-45% of the volume occupied by the hydrocarbons in the reservoir.9

Because of differences in density and viscosity between the injected fluid and the reservoir fluids, the miscible process often suffers from poor mobility. Viscous fingering and gravity override frequently occur. The simultaneous injection of a miscible agent and brine is suggested in order to take advantage of the high microscopic displacement efficiency of the miscible process and the high macroscopic displacement efficiency of a waterflood.

Several variations of the simultaneous injection scheme are suggested. They typically involve the injection of a miscible agent followed by brine or the alternating of miscible agent-brine injection. The latter variation has been named the WAG (water alternating gas) process and has become the most popular.

A balance between amounts of injected water and gas must be achieved. Too much gas will lead to viscous fingering and gravity override of the gas, whereas too much water could lead to the trapping of reservoir oil by the water. The addition of foam-generating substances to the brine phase has been suggested as a way to aid in reducing the mobility of the gas phase.

The highest oil recovery efficiencies are associated with the implementation of the tapered WAG injection technique where the ratio of injected water to CO2 changes with time, starting with larger CO2 slugs that are progressively reduced in size.10

The main issues in implementing CO2 EOR in Egypt are:

• Corrosion of some infrastructure already in place that was not designed for CO2 use when initially installed.

• Increased capital expenses for modifying the existing infrastructure and purchasing and installing additional equipment such as CO2 compressors.

• Capital and operating expenses for the construction and operation of a CO2 pipeline network.

• Uncertainty surrounding the legal framework for CO2 underground storage.

• Need for coordination and agreement between CO2 source companies and the oil producers for the execution of the EOR projects.

References

1. Alvarado, V., and Manrique, E., "Enhanced oil recovery: An update review," Energies, Aug. 27, 2010, p. 1,529.

2. Natural Gas Engineering Diploma, Graduation Project Reports, Mining Studies & Research Center (MSRC), Cairo University, 2012.

3. Sayyouh, M.H., and Al-Blehed, M., "Screening criteria for enhanced recovery of Saudi crude oils," Energy Sources, Vol. 12, Issue 1, 1990, p. 71.

4. Taber, J.J., Martin, F.D., and Seright, R.S., "EOR screening criteria revisited-Part 1: Introduction to screening criteria and enhanced recovery field projects," Paper No. SPE 35385-PA, SPE Reservoir Engineering Journal, August 1997, p. 189.

5. Donaldson, E.C., Chilingarian, G.V., and Yen, T.F., Enhanced oil recovery: Fundamentals and analysis, New York: Elsevier Science Publishing Co. Inc., 1985.

6. Carcoana, Aurel, Applied Enhanced Oil Recovery, New Jersey: Prentice-Hall Inc., 1992.

7. Cronquist, C., "Carbon dioxide dynamic displacement with light reservoir oils," presented at the 1978 US DOE annual EOR symposium, Tulsa, Aug. 28-30, 1978.

8. Manrique, E.J., Muci, V.E., and Gurfinkel, M.E., "EOR field experiences in carbonate reservoirs in the United States," SPE 100063-PA, SPE Reservoir Evaluation & Engineering Journal, December 2007, p. 667.

9. Tzimas, E., Georgakaki, A., Garcia Cortes, C., and Peteves, S.D., "Enhanced oil recovery using carbon dioxide in the European energy system," Report EUR 21895 EN, European Commission, Directorate General, Joint Research Centre, Institute for Energy, Petten, the Netherlands, December 2005.

10. Schulte, Willem, "Experience for use in CO2 for enhanced oil recovery in the USA," presented to the 2004 CO2 Conference, Norway.

The authors

Mahmoud Abu El Ela ([email protected]) is an associate professor at the Petroleum Engineering Department, Cairo University, and an associate professor in the university's Petroleum and Petrochemicals Engineering Consultants Group (PPEC Group). He is also a manager of projects (acting) at WorleyParsons Engineers Egypt Ltd.

Previously he was a lead process engineer at WorleyParsons, assistant professor at the petroleum engineering department at Cairo University, petroleum process consulting engineer for Khalda Petroleum Co., and a research engineer at Woodside Research Foundation (Curtin University of Technology, Australia). Since 1997, he has been a technical consultant in petroleum engineering for national and international companies. He holds a BSc and MSc in petroleum engineering from Cairo University and a PhD from Curtin University.

Helmy Sayyouh ([email protected]) is a professor in the petroleum engineering department, Cairo University, and a professor in the PPEC Group. Since 1986, he has been a consulting engineer in the areas of petroleum reservoir engineering, enhanced oil recovery, reservoir simulation, and natural gas engineering. He was a consultant in Geisum Oil Co. in 1995-96 and an active member in the Egyptian National Petroleum High Committee in 1995-2000. He holds BSc and MS degrees in petroleum engineering from Cairo University and a PhD from Penn State University.

El Sayed El-Tayeb ([email protected]) is a professor in the petroleum engineering department, Cairo University, and a professor in the PPEC Group. He is the director of the Mining Studies & Research Center (MSRC) at Cairo University. Since 1998, he has been a consulting engineer in petroleum reservoir engineering and enhanced oil recovery. He holds a BSc and MSc in petroleum engineering from Cairo University and a PhD from Laboratories des Sciences du Genie Chimique, ENSIC Nancy University.