Scale formation hinders gas injection wells in Iran's Kupal, Maroun oil fields

Maryam Asemani

Fateh Sanat Kimla Co.

Shiraz, Iran

Feridun Esmaeilzadeh

Dariush Mowla

Shiraz University

Shiraz, Iran

Damoon Ranjbar

University of British Columbia

Vancouver, BC

Vahid Khorshidi

Polytechnic University of Milan

Milan, Italy

Scale formation is a critical problem for gas injection-well operators in southern Iranian oil fields. Scale precipitation can restrict gas injection, resulting in complete injection blockage.

Gas injection wells maintain reservoir pressure and provide enhanced oil recovery in Kupal and Maroun oil fields where the authors studied scale composition, scale sources, and the mechanics of scale formation.

Analysis revealed sodium chloride (NaCl) was the major contributor to precipitates caused by unwanted water in gas-injection wells, the formation water's high salinity creating a strong tendency for salt precipitation. Petrophysical data and temperature profiles for Kupal and Maroun study wells confirmed most of the unwanted water came from the Gachsaran formation.

Scale deposition in gas injection wells typically caused problems within months of the injection wells starting operation. Cost-effective remediation used X-ray diffraction (XRD) and X-ray fluorescence (XRF) to locate and characterize scale deposit compositions.

Cement-bond logs (CBL), variable density logs (VDL), and temperature profiles for wells in Kupal and Maroun oil fields showed a poor cement-casing bond in wells with precipitation inside the tubing.

Maroun, Kupal fields

Maroun oil field in Khuzestan province contains estimated reserves of 22 billion bbl and produces 520,000 b/d, making it the sixth biggest onshore field worldwide as well as Iran's second most prolific field. National Iranian Oil Co. (NIOC) owns the field, discovered in 1963, and National Iranian South Oil Co. (NISOC) operates it.

NIOC discovered Koupal oil field in Khuzestan Province, 60 km east of Ahvaz City, in 1965. The company estimates proved reserves at 10 billion bbl. The field is 60 km long, 1.5 km wide, and includes Asmari and Bangestan reservoirs.

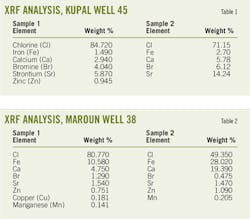

Field observations of salt precipatates in gas wells proved salt can accumulate in the wellbore, perforation zone, and reservoir. XRF determined the precipitation composition, analyzing a wide range of specimens in solid, powder, and liquid states. The elements distinguished ranged from silicon to uranium.

Quantitative XRF analysis required comparing measured radiation intensities with the concentration of the elements found. The process acknowledged relationships between the sample's source intensity, concentration, overall composition, and absorption properties.

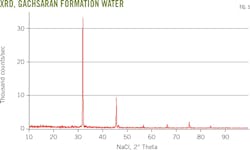

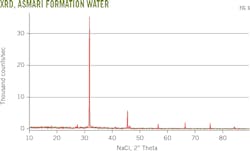

XRD analyses determined the mineral composition of the raw material components and performed qualitative and quantitative phase analysis of the multiphase mixtures.

Researchers used K-alpha electron spectroscopy with a graphite secondary monochromator and a scintillation-counter detector. They put a powdered sample of precipitates on a flat plastic plate, rotated at 30 rpm. Researchers ran scans at 25° C. in steps of 0.04° timed 2 sec apart.

Software helped identify the samples' mineral compounds. Scanning electron microscopy (SEM) determined the size distribution and morphology of salt crystals. Testers dried sample fragments at room temperature and coated them with gold for the SEM process.

The cross-sections were embedded in epoxy resin before being cut and polished using sandpaper and successive diamond pastes of 1, 3, and 6-μm diameter.

Immersion in alcohol prepped the cross-section surfaces for ultrasonic cleaning. Researchers observed sample surfaces and cross-sections using an accelerating-voltage microscope.

Precipitate analysis

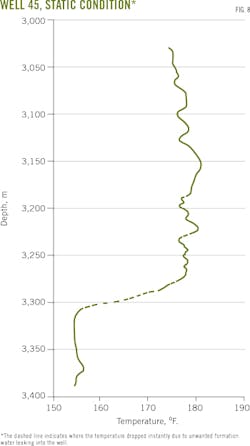

XRF determined precipitate composition. Table 1 shows the results of XRF analysis performed on scale samples from Kupal gas injection wells. Chloride quantities were large compared with trace amounts of other elements.

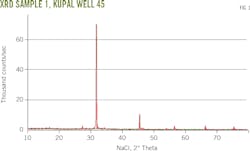

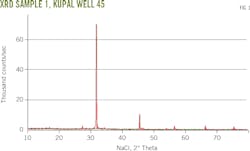

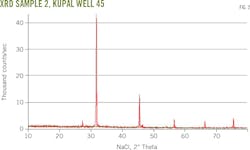

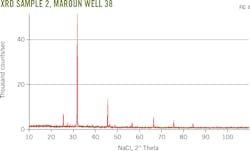

Figs. 1-4 show XRD analysis for well samples from Kupal and Maroun oil fields. The authors used software to analyze X-ray diffraction data both quantitatively and qualitatively, comparing the raw intensity data of an XRD pattern with diffraction results from numerical computation of each mineralogical phase in the sample.

Assessing the typical sequence of line profiles and relative intensities created fingerprints for each substance, validating the mineralogical phase.

XRD analysis confirmed NaCl as the main compound found in the samples. SEM results show different sizes and morphologies of sample crystals (Figs. 5-6).

Unwanted water from Gachsaran or Asmari formations contributed to most precipitation in the gas injection wells. Dry gas injected into the wells vaporized wellbore water, resulting in precipitates. Researchers compared water analysis with precipitate analysis.

Chemical analysis of field water was pivotal in understanding gas injection well scaling problems. Researchers filtered water samples using ashless filter papers.

Water from Gachsaran and Asmari formations had identical mineral composition and nearly identical concentrations (Tables 1-2). Formation water from both Gachsaran and Asmari had high chlorine concentrations.

NaCl concentrations in Gachsaran formation water were slightly higher than in Asmari formation water. Researchers could not determine scale sources from chemical analysis of the water, but XRF spectrometry confirmed NaCl constituted much of the scale.

Researchers also used temperature profiles to evaluate injection wells in Kupal and Maroun fields. Poor mechanical casing integrity enabled water entry. Corrosion caused casing holes. Casing flaws, excessive pressure, and formation deformation caused wear and splits that also allowed entry of unwanted reservoir fluids.

Most casing leaks occurred above the cement. Knowledge of precipitation depth was essential to scale-removal.

Sonic-bond tools or cement-bond tools transmitted a signal to casing and formation. Researchers measured the magnitude and time of the refracted signals. The strength and transit time of the refracted signals provided information about the casing-cement bond, cement density, and cement-formation bond.

Wells with a good cement-casing bond displayed attenuated sonic waves. But returning signals showed little attenuation in wells with a poor cement-to-casing bond.

VDL data supplemented information from CBL, using a full-wave display of the 5-ft receiver signal. CBL data provided an amplitude curve and demonstrated the quality of the casing-cement bond.

VDL logs provided a wave train of received signals, indicating the quality of the casing-cement bond as well as the quality of the cement-formation bond. Signals passing directly through casing showed up as parallel straight lines to the left of the VDL plot. Wavy lines to the right of the VDL plot indicated a good casing-cement and cement-formation bond. Wavy lines represented signals that passed through the formation, reflecting from the cement and casing to the receiver. Experiments investigated well integrity, cement quality, and the cement-casing bond.

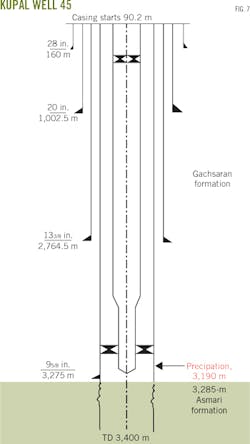

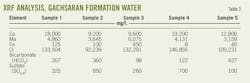

Fig. 7 shows a schematic of Kupal Well 45. The well's interval at 3,285-3,400 m is Asmari formation.

Fig. 8 shows the temperature profile and the depth of precipated samples taken from Kupak Well 45. Temperature profiles helped locate unwanted water leaks into the well. Temperature decreased in the lower Gachsaran formation (3,260 m), indicating where water entered the well.

CBL-VDL logs show salt precipitate inside tubing at 3,150-3,200 m. Cement quality and the cement-casing bond were determined to be poor because the signals did not reach the formation. Parallel lines were recorded across the VDL plot. Weak cement allowed reservoir fluid into the well.

Well 38 of Maroun oil field involved both formations: the Gachsaran formation down to 2,484 m and the Asmari formation below that.

Temperature profiles also helped locate water leaks in Well 38.

CBL-VDL logs obtained from 2,350-2,425 m show poor cement quality and a poor cement-casing bond, contributing to reservoir fluid leakage.

Acknowledgments

The authors are grateful to the Shiraz University and National Iranian South Oil Co. for supporting this research.

Bibliography

Cosultchi, A., Garciafigueroa, E., Mar, B., Garcia-Borquez, A., Lara, V.H., and Bosch P., "Contribution of organic and mineral compound to the formation of deposits inside petroleum wells," Fuel, Vol. 81, No. 4, March 2002, pp. 413-421.

El-Said, M., Ramzi, M., and Abdel-Moghny, T., "Analysis of oilfield waters by ion chromatography to determine the composition of scale deposition," Desalination, Vol. 249, No. 2, Dec. 15, 2009, pp. 748-756.

Kamath, J., and Laroche, C., "Laboratory-based evaluation of gas well deliverability loss due to waterblocking," Society of Petroleum Engineers Annual Technical Conference and Exhibition, Dallas, Tex., Oct. 1-4, 2000.

Kleinitz, W., Koehler, M., and Dietzsch, G., "The Precipitation of Salt in Gas Producing Wells," SPE European Formation Damage Conference, The Hague, Netherlands, May 21-22, 2001.

Kodel, K.A., Andrade, P.F., Valenca, J.V.B., and Souza, D.N., "Study on the composition of mineral scales in oil wells," Journal of Petroleum Science and Engineering, Vol. 81, January 2012, pp. 1-6.

Mahadevan, J., and Sharma, M. "Clean-up of water blocks in low permeability formations," SPE Annual Technical Conference and Exhibition, Denver, Oct. 5-8, 2003.

Nieuwland, H.F., and Collins, I.R., "Groet 1 Scale Study: Analysis, Diagnosis & Solution Implementation," SPE International Symposium on Oilfield Scale, Aberdeen, May 26-27, 2003.

Place M.C., and Smith, J.T., "An Unusual Case of Salt Plugging in a High-Pressure Sour Gas Well," SPE Annual Technical Conference and Exhibition, Houston, Sept. 16-19, 1984.

Tang R., and Etzion, Y., "Comparative studies on the water evaporation rate from a wetted surface and that from a free-water surface," Building and Environment, Vol. 39, No. 1, January 2004, pp. 77-86.

Tucker, M.E., "Sedimentary Petrology: An Introduction to the Origin of Sedimentary Rocks," 3rd Ed., Wiley-Blackwell, Hoboken, NJ, 2001, pp. 166-181.

Zuluaga, E., and Monsalve, J.C., "Water Vaporization in Gas Reservoirs," SPE Eastern Regional Meeting, Pittsburgh, Pa., Sept. 6-10, 2003.

The authors