Study assesses CO2 EOR potential by pore structure in China's Changqing field

Yibing Yu

Moh'd Amro

Freiberg University of Technology

Freiberg, Germany

Foppe Visser

Wintershall Holding AG

Kassel, Germany

Fulong Ning

Rui Li

China University of Geosciences

Wuhan, China

Recent studies investigated how pore structures influenced enhanced oil recovery (EOR) in China's Changqing field, where CO2 pilots are under way despite recovery efficiency methods having not yet been optimized.

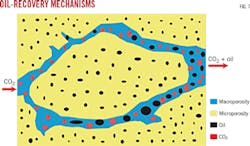

Carbonate reservoirs are complex, largely because of dual-porosity pore systems. Macroporosity regions feature pores enabling effective fluid flow and oil production. Microporosity regions provide limited permeability, resulting in oil entrapment.

Tests on core samples from the US states of Indiana and Wisconsin found similar porosity and permeability to Changqing. The samples showed dual-porosity, classified into micro and macro types with a 1 μm pore-size serving as the threshold.

Dominant gas flow changed from Darcy flow to diffusion when pore diameters changed from macro to micro. CO2 flows through the macropores and produces oil by Darcy flow. Micropores yield oil mainly by diffusion in lower-permeability samples. Researchers evaluated the efficiency of CO2 diffusion for oil extraction from different porosity core samples.

PetroChina Co. Ltd. operates Changqing field in the Ordos basin. Baker Hughes Inc. has characterized Changqing as having low permeability, low pressure, and low-yield sands (OGJ, June 14, 2010, p. 10).

Heterogeneity

The complex heterogeneous pore-structure inside carbonates is closely linked with permeability and fluid movement. Heterogeneity can contribute to low recovery.

Literature shows earlier pore-dimension studies used mercury injection capillary pressure (MICP), nuclear magnetic resonance (NMR), scanning electron micrograph (SEM), gas adsorption, computed tomography, and digital-image analysis.1-2

Carbonate reservoirs demonstrate pore diversity, which contributes to low porosity-permeability correlation. Higher porosity typically means higher permeability, but the relation between porosity and permeability in carbonate reservoirs is complex.3

Carbonate reservoir fluid flow research continues to emphasize microporosity's ability to increase connectivity of macropores, boosting overall permeability.4-5 Various criteria classify carbonate by pore size, rock fabric, and other properties. Areas of porosity are divided into macroporosity and microporosity to help define complex pore characteristics. Microporosity values are in the 0.3-62.5 μm range, and macroporosity values in the range of 4 μm to 4 mm.

Pore types also are defined by anticipated contribution to permeability. Knudsen theory enabled analyzing oil-recovery mechanisms for different pore types based on calculated gas flow in porous media. Testers used decane in the laboratory to stimulate oil-saturated core samples during CO2 flooding.

Experimental procedure

Experiments used two sizes of outcrop limestone: 50 mm in diameter × 100 mm long and 25 mm in diameter × 60 mm long. Gas permeability was 9 md, 15-20 md, and 200 md for the three Indiana limestone samples and 0.004 md for the Wisconsin limestone sample. Corresponding porosities were 19%, 14%, 18%, and 3%.

Unsteady-state permeability measurements quantified rock heterogenety.MICP technology also was used to analyze gas flow through different pore sizes. Core-flooding experiments observed the response of pore characteristics to CO2 injection and oil recovery.

Fig. 1 depicts the core flooding experiment. Samples were dried at 80° C. for 24 hr and placed in a core holder for vacuum treatment. Cores were saturated with 3.5% sodium chloride, stored for 10 hr and then flooded with 1 ml/min of decane until no brine exited the outlet, establishing water saturation as the difference between entered brine and displaced brine.

After soaking, workers injected CO2 at 0.15 ml/min and monitored oil production.

Workers closed the oil outlet once CO2 broke through, maintained 5 MPa for 12 hr, and then slowly reopened the outlet for more CO2 injection until breakthrough resumed.

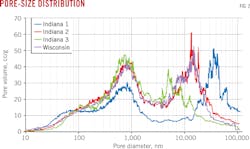

The experiment indicated pores of 10 nanometer (nm) to 100 μm. Fig. 2 shows that all four limestone samples demonstrated typical bimodal-pore characteristics.

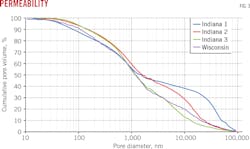

Fig. 3 shows cumulative pore volume for four samples having different permeability. Cumulative pore volume was divided using a critical 1 μm pore size. Higher-permeability samples had larger cumulative pore volume above the critical pore size as did high-porosity samples.

Permeability was controlled primarily by macroporosity (pore sizes above 1 μm). Pore sizes less than 1 μm contributed little to permeability. Greater explanation of microporosity's quantitative effect on permeability in carbonates lies outside the scope of this article, but can be found in previous research.6-8

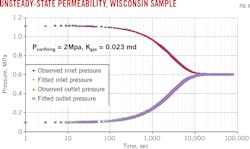

Each sample, especially the Wisconsin sample, was low permeability. Researchers used the unsteady-state method to measure permeability, monitoring CO2 pressure in the inlet and outlet.

A numerical model resolved the partial differential equation of unsteady-state flow to determine the samples' permeability and porosity. Fig. 4 shows the Wisconsin sample's permeability measurements under simulated pressure with nitrogen. The unsteady method was particularly suitable for rocks with expected permeability less than 10 md. Results were unreliable for higher-permeability samples due to the short time (<100 sec) for complete pressure equalization.

Table 1 lists the permeability and porosity properties for the three limestone samples. Except for the Indiana 1 sample, permeability trends down with increasing confining pressure as measured by unsteady state experiments. The method proved less suitable for the Indiana 1 sample, with an expected permeability of around 200 md.

Time required for complete pressure equalization was 20 sec, making the unsteady-state measurement for Indiana 1 unreliable and leaving researchers to rely on permeability data provided by the sample supplier.

When combining the permeability and porosity properties from the supplier and the unsteady-state experiments, porosities of the investigated samples were within 20%. Permeabilities, however, varied greatly.

MICP experiments demonstrated the permeability-porosity relationship. Total porosity can be divided into microporosity or macroporosity by contribution to permeability. Microporosity appears to have no contribution to Darcy permeability, but its effect on flow and transport should be further investigated.

Gas flow

Oil production in conventional reservoirs comes primarily from their macropores. Large amounts of oil are left in microporosity regions. Gas-flow regimes helped evaluate the possibility of recovery from micropores.

Equation 1 demonstrates how CO2 transportation varies. Equation 2 shows the free path of gas molecules in a Lattice Boltzmann flow simulation.

CO2 transportation in macropores can be described by Darcy flow. Non-Darcy flow, especially diffusion, becomes the dominant transportation in micropores

The authors relied on field data from 28 CO2 tests in Texas where CO2 transport patterns in pores of different scale were studied.9

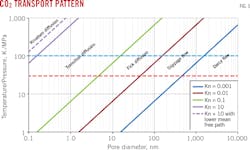

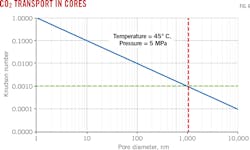

Fig. 5 shows temperature and pressure variation in the field cases. Its four lines show five parts: Darcy flow, slippage flow, Fick diffusion, transition diffusion, and Knudsen (Kn) diffusion. Darcy flow appears in macropores larger than 1,000 nm in diameter.

CO2 transport relies on diffusion in regions where microporosity has low permeability. Fig. 6 represents ideal gas properties and illustrates real gases' shift toward smaller pore sizes.

Fig. 6 also shows how CO2 flow regimes are sectioned by Darcy flow and non-Darcy flow at a 1 μm pore threshold, which agrees with the anticipated contribution of microporosity and macroporosity to permeability.

Dominant CO2 flows in porous media change from Darcy flow to diffusion with the reduction of pore sizes from macro to micro. CO2 preferentially flows through the connected macropores by Darcy flow, producing oil through viscous flow during CO2 flooding. Oil in micropores is bypassed unless enough time exists for diffusion to provide contact and subsequent mixing between oil and CO2.

Residual oil saturation in heterogeneous carbonates is related to relative percentages of macropores and micropores. Residual-oil saturations of 20-30% were found in micropores compared with 10% in macropores.

The CO2 flow regime in micropores does not contribute to Darcy permeability. Diffusion is a dominant mechanism for oil recovery from micropores and other bypassed regions.10

Fig. 7 shows different mechanisms of oil recovery from micro- and macropores by CO2 injection in fractured tight reservoirs.

CO2 injection

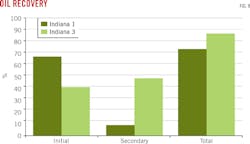

Table 3 shows water saturation results for Indiana 1 and Indiana 3 samples after CO2 flooding experiments. Temperatures and pressures for all experiments were kept below critical conditions to ensure immiscibility.

Table 4 lists results of the core flooding experiments with CO2 injection. The first shows oil recovery before CO2 breakthrough in the outlet and the second oil recovery represents recovery after 12 hr of soaking.

Equations 3-4 show that the 12-hr diffusion length of CO2 in Indiana 1 and Indiana 3 was enough for samples with diameters up to 25 mm.

Macropores controlled permeability and produced oil during first-stage viscous flow. Micropores provided low permeability, with diffusion acting as the oil recovery mechanism in the second stage. Fig. 8 shows first-oil recovery in the higher-permeability sample as higher than the lower-permeability sample.

Low-permeability samples realized higher total oil recovery than the higher-permeability samples. Indiana 3 demonstrated higher second-oil recovery than first-oil recovery. Comparison of the two samples shows diffusion-driven oil recovery from micropores as better in low-permeability environments than high permeability.

Oil production from low-permeability samples depends on effective flow mechanisms through porous media. Flow in low-permeability samples can be quite different from flow in high-permeability samples. When pore sizes decrease to nanometer range, free gas molecules follow a mean free path guided by flow-channel diameters. Molecules strike and slip the pore walls frequently. Knudsen theory helps evaluate molecular-pore wall collisions' effect on flow and transport.

Darcy's law helps determine flow capacity in high-permeability samples. Knudsen diffusion and other diffusive flow mechanisms in micropores benefit permeability forecasting, resulting in a value greater than the Darcy prediction. Additional research is needed to better understand permeability's role in diffusion's oil-recovery efficiency.

Acknowledgment

The authors thank the Institute of Drilling Engineering and Fluid Mining of Freiberg University of Technology and Jiangsu Ke Petroleum Instrument Co. Ltd. for assisting with the experiments.

References

1. Sok, R.M., Knackstedt, M.A., Varslot, T., Ghous, A., Latham, S., Sheppard, A.P., "Pore scale characterization of carbonates at multiple scales: Integration of Micro-CT, BSEM, and FIBSEM," International Symposium of the Society of Core Analysts, Noordwijk, Netherlands, Sept. 27-30, 2009.

2. Denney D., "Digital Core Laboratory: Reservoir-Core Properties Derived from 3D Images," Journal of Petroleum Technology, Vol. 56, No. 5, pp. 66-68, May 2004.

3. Dou, Q., Sun, Y., Sullivan, C., "Rock-physics-based carbonate pore type characterization and reservoir permeability heterogeneity evaluation, Upper San Andres reservoir, Permian basin, west Texas," Journal of Applied Geophysics, Vol. 74, No. 1, pp. 8-18, January 2011.

4. Apourvari, S.N., and Arns, C.H., "An assessment of the influence of microporosity for effective permeability using local flux analysis on tomographic images," International Petroleum Technology Conference (IPTC), Kuala Lumpar, Dec. 10-12, 2014.

5. Fullmer, S.M., Guidry, S.A., Gournay, J., Bowlin, E., Ottinger, G., Al Neyadi, A.M., Gupta, G., Gao, B., Edwards, E., "Microporosity: Characterization, distribution, and influence on oil recovery," IPTC, Kuala Lumpar, Dec. 10-12, 2014.

6. Yu Y., Visser, F., and Amro, M.M., "Quantitative Effect of Microporosity on Permeability in Carbonate Reservoirs," IPTC, Kuala Lumpar, Dec. 10-12, 2014.

7. Amro, M., and Freese, C., "Novel Laboratory Measurement for the Characterization of Tight and Shale Formations during Transient (Unsteady State) Flow Regime," Society of Petroleum Engineers Middle East Oil & Gas Show and Conference, Manama, Bahrain, Mar. 8-11, 2015.

8. tory Measurement of Permeability and Porosity to Prove Tightness of Underground Storage of Hydrogen, Natural Gas, and CO2," SMRI Fall Technical Conference, Bremen, Germany, Oct. 1-2, 2012.

9. Haskin, H.K., and Alson, R.B., "An evaluation of CO2 huff'n'puff tests in Texas," Journal of Petroleum Technology, Vol. 41, No. 2, February 1989, pp. 177-184.

10. Yibing, Y., and Moh'd, M.A., "Response of CO2 Diffusions to Macro- and Microporosity in Carbonate Reservoirs," SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, Oct. 11-14, 2015.

The authors

Yibing Yu ([email protected]) is a PhD candidate at the Institute of Drilling Technology and Fluid Mining at Freiberg University of Technology. His work focuses on CO2 EOR. Yu earned his MS (2012) from the China University of Geosciences-Wuhan. His research specializes in unconventional oil and gas, especially CO2 EOR in heterogeneous and low-permeability carbonates.

Moh'd Amro ([email protected]) is a professor and director of the Institute of Drilling Technology and Fluid Mining at Freiberg University of Technology. He previously was with the petroleum engineering department of King Saud University, Saudi Arabia. He received his MS (1991) and PhD (1994) from the Technical University of Clausthal, Germany. He focuses on underground storage, tertiary oil recovery, geothermal energy resources, and unconventional oil and gas exploration and development.

Foppe Visser ([email protected]) is a visiting professor at Institute of Drilling Technology and Fluid Mining at Freiberg University of Technology. He also works for Wintershall Holding GmbH as a research and development manager and senior advisor. Visser has been with Wintershall since January 2007. He started his reservoir engineering career with Royal Dutch Shell. He holds an MS from the VU University, Amersterdam, and a PhD in theoretical chemistry from Radboud University, Nijmegen.

Fulong Ning ([email protected]) is an engineering professor at China University of Geosciences-Wuhan. He received his PhD in geological engineering (2005) from China University of Geosciences-Wuhan. Fulong's postdoctoral research was done at the Norwegian University of Science and Technology (2009-10). His research interests include exploration and development of unconventional natural gas, especially gas hydrates and shale gas.

Rui Li ([email protected]) is studying for his MS while working in the engineering faculty of China University of Geosciences-Wuhan from which he received a BS (2015). His MS research focuses on gas hydrate exploration and development in China.