UNCONVENTIONAL GAS TECHNOLOGY—2: Custom technology makes shale resources profitable

Low permeability shales are unconventional gas reservoirs that are being more efficiently exploited with newly developed production technologies.

This series began last week, with an article discussing advances in fracture stimulation techniques and fluids used to improve tight gas production (OGJ, Dec. 17, 2007, p. 39).

The final article in this series, to be published next month, deals with coalbed methane (CBM) production.

Shales

There are technical difficulties in producing gas from shales, which have ultralow permeabilities and vary in brittleness. Multilayered shale reservoirs have widely varying reservoir characteristics and flow mechanism regimes. Formations typically have high capillary pressures in hydraulic fracturing scenarios. Treatment fluids can potentially damage shale formations.

Multilayered shale reservoirs with a variety of reservoir characteristics require specialized evaluation and drilling techniques and “next-well” geological, seismic, and production comparisons to identify optimum fracturing targets.

All of these data sources can be fed into custom models for a potential well’s production design. Combining logging systems with next-well and field-wide properties, geomechanics, and production performance data forms the basis of an advanced modeling system. The system is tailored for the specific shale-production mechanism and composition of the proposed new well’s drilling and completion design. Placing the well’s target location is critical and can be done with economical, simplified, rotary-steerable drilling assemblies in land-based shale wells.

Determining proper fracture placement within shale formations is a key to creating large, highly productive fracture networks. Logging systems use an innovative approach, incorporating select mechanical rock properties, geomechanics, total organic content, and porosity to help locate the best fracture-initiation points within shale formations. Microseismic methods also provide invaluable information on the depth and width of the multiple fractures that are created during fracture stimulation.

Due to shale’s ultralow permeability, successful economic productivity from a shale reservoir depends on the capability to maximize formation exposure through horizontal or vertical drilling and fracturing, or both.

Economical rotary-steerable drilling assemblies, high-horsepower fracturing units, and multifunctional fracture-placement techniques provide maximum and optimized reservoir exposure.

A complex reservoir’s brittleness must be leveraged through drilling and fracturing to create as much fracture face as possible to maximize gas migration from the producing shale. Brittleness can also be leveraged to create formation exposure through the use of high-horsepower fracture pumping units, which have been developed to provide maximum fracturing horsepower in a reduced environmental “footprint.”

New designs include increased horsepower and high-rate pumps and offer improved safety, performance, reliability, space utilization, operational efficiency, real-time automation throughout the entire fracturing system, and ultimate improved gas recovery.

Multilayer reservoir characteristics and ultralow formation permeability require precision fracturing of optimum locations along the wellbore, which has led to significantly improved production results.

Pinpoint stimulation techniques have evolved, making shale more profitable as gas prices cycle. Multiple zones can be efficiently fractured independently by:

- Using coiled tubing or tubulars with hydrojetting techniques.

- Using dynamic diversion techniques for either vertical or horizontal placement.

- Or, incorporating completion mechanical downhole assemblies featuring stimulation sleeves and swellable elastomer packers to enable stimulation of multiple zones without use of bridge plugs to isolate intervals to be treated. These pinpoint stimulation techniques offer operators cost-effective methods to stimulate multiple zones in one rig-up.

Fluid treatment

Ultralow permeability is the primary challenge in shale formations. Fracturing fluids that are nondamaging and that enhance load recovery is essential in shale formations with very limited permeability. A combination of specialized chemistries delivers maximum effective fractures and preserves the formation’s existing permeability to gas, contributing significantly to the shale-production success. Components of the fracture fluids include:

- Special friction reducers formulated to reduce potential fracture-face damage caused by long-chain polymers, without compromising their capability to reduce friction pressure.

- Microemulsion surfactant that helps reduce capillary pressure, releasing imbibed treatment water and improving gas permeability. It also provides significant safety and environmental benefits by replacing methanol in water-block treatments.

- Fracture-cleaning enhancer and conductivity enhancer for accelerating fracture cleanup and flowback of treatment fluids.

Together, these components create a synergistic fluid treatment solution designed to help optimize gas production from formations with ultralow native permeability. The system provides workable, cost-efficient solutions for shale productivity programs from beginning to endfrom analysis and planning to drilling, fracturing, early production, long-term production, and ultimate recovery/abandonment.

The ability rapidly to fracture multiple independent zones yields a significant decrease in completion time. The components of the system work together to provide a synergistic solution targeted specifically at changing a potential resource into an important energy producer.

Multilayer reservoirs

Multilayered reservoirs exhibit a wide range of reservoir characteristics that need to be evaluated, modeled, and monitored.

A shale-specific modeling and analytical system evaluates formation mechanical properties, total organic carbon content, shale maturity, vitrinite reflectance, gas content in scf/ton, and free and adsorbed gas content. Specialized shale-logging analyses, reservoir simulation, production history matching, injection test analysis, microseismic, and overall field characteristics help to inform new well or new field development decisions. (Microseismic applications are “trained” by data from adjunct wells or fields.)

Passive microseismic fracture monitoring (PMM) applications include mapping the extent of fractures during hydraulic-fracture treatments, fault mapping, and tracking a gas or water front for assisted recovery production. To exploit the benefits of PMM, a recently developed technology combines logging and borehole seismic with the science of microearthquakes to allow the monitoring of fractures while they are created. With this assist, fracturing engineers can obtain the answers they require.

This approach to logging offers:

- Dipole sonic used for pre-stimulation vertical stress profile modeling.

- Velocity profile for borehole seismic modeling.

Fiberoptic monitoring provides temperature profiles over the entire length of the well during the stimulation treatment. Comparing and analyzing temperature profiles over time provides direct indications of injection distribution at various points in the wellbore. The real-time information allows immediate optimization of the treatment and postjob follow-up to aid in future treatment optimization.

Capillary pressure

Shales often have high capillary pressures. A unique microemulsion surfactant helps control fluid-induced fracture-face damage during hydraulic fracturing and helps release trapped water and increase production in low-pressure, tight formations. This surfactant helps reduce fracture-face damage caused by phase trapping; enhances mobilization of liquid hydrocarbons (including condensate); helps increase regained permeability to gas following treatment; improves load recovery; improves environmental and safety performance by replacing methanol; and is effective in reservoirs with matrix permeability in the nano-Darcy range.

Formation damage

A new friction reducer helps reduce fracture-face damage from long-chain polymers. The maximum horsepower can be applied in a shale formation rather than being wasted just to get the fluid through the mechanical system. Because this reducer contains no phenols, it provides improved environmental performance and exhibits less flocculation than conventional friction reducers.

A viscosity-reducing agent helps maximize the effectiveness of water-fracturing treatments by reducing fluid viscosity, improving load recovery, minimizing friction-reducer polymer damage, and preventing polymer adsorption to the fracture face, thereby enabling improved production.

These purpose-focused technologies provide a holistic and economical approach to bringing forth energy from unconventional shale resources. Two cases demonstrate the use of the shale production system (SPS):

- Case 1. A horizontal shale well was stimulated at four intervals with stimulation sleeves sequentially to isolate each interval of interest during treatment. The four intervals were fractured in 15 hr, placing 1.2 million lb of proppant with 2.3 million gal of fluid in a continuous operation.

Normal stimulation practices would have required 2 days to run four traditional fracturing stages. The operational efficiency gained through the use of the stimulation-sleeve process reduced completion costs by 15-20%. - Case 2. Gas sales from six Barnett shale wells were compared after three of the wells had been treated with SPS additives and three were treated without additives. First gas production was quicker in the three wells treated with SPS additives and these wells produced 100% more gas sales/day.

The Mississippian Barnett shale serves as source, seal, and reservoir in a world-class unconventional natural gas accumulation in the Fort Worth basin of northcentral Texas. The Barnett is lithologically complex, with low permeability, and requires artificial stimulation to produce.1 - Case 3. Ten horizontal shale wells in Oklahoma were recently completed with massive slick-water fracturing. Four of these wells were fractured with microemulsion surfactant (MS) and six wells did not have the MS treatment.

The MS treatment reduced water saturation and capillary pressures along the fracture faces, which improved relative permeability to gas. Wells using the MS service had initial gas production among the best wells in the field.

Life-cycle phases

Operators producing gas from shale reservoirs can be more successful by following the five life-cycle phases of project development and carefully choosing technologies appropriate for each project phase:

- Reservoir assessment. Evaluate shale and reservoir potential.

- Start-up exploration. Drill experimental wells and investigate fracture design and production prediction.

- Early development (mass production). Rapidly develop using an optimized design. Develop database and benchmarks.

- Mature development (reserve harvesting). During this cash-flow cycle, match production histories; adjust reservoir model; image database.

- Declining phase (maintenance and remediation). Identify remedial candidates, restimulate, initialize lift mechanisms and conformance methods.

(Similar coalbed methane life-cycle phases are discussed in the final article in this series.2)

Prospect evaluation

Usually, the first step in the design and application process is to evaluate the shale prospect. Initially, both 2D and 3D seismic data are processed to determine the extent of the shale play. The volume of shale is estimated in tons/acre (ton/acre-ft). Gas in place (GIP) is calculated from the geochemical determination of standard cubic feet/ton (scf/ton), as follows: GIP = (ρ)(1,359)(scf/ton) = scf/acre-ft.

Shale samples collected from various sources help in determination of the commercial viability of the project. Factors include:

- Shale hydrocarbon content (scf/ton, bbl/ton, GIP).

- Shale maturity.

- Kerogen type (Types I and II, oil; Type III, gas).

- Shale porosity, permeability, oil, water, and gas saturations.

- Shale desorption constant, or gas isotherm.

- Shale bulk density, ρ (g/cu cm).

Log data requirement

A triple-combo log can be used to obtain density, gamma ray, resistivity, neutron, and density porosity.

A wave-sonic log should be run to obtain mechanical rock properties.

An EMI (electromagnetic imaging) tool should be run to obtain natural and induced fracture direction, followed by analysis to identify sweet spots and a fracture-initiation site.

A pulsed spectral gamma (PSG) log enhances oil recovery by accurately measuring oil saturations over a wide range of properties and borehole conditions. The PSG log also aids in clay typing, which adds to knowledge of the reservoir and is helpful information for planning future wells.

Enhancing production

Commercial production from shale depends largely on the gas content and natural storage and deliverability of the rock. The prime goal of stimulation is to contact and expose the greatest amount of rock volume and surface area with the least expensive material; in effect, “mining” the shale using hydraulic horsepower and injected water. This hydraulic mining can turn a well in nano-Darcy shale into a commercial gas producer.

Restimulation has proven to increase recoverable reserves by 50-100%. Future vertical and horizontal wells are likely to be completed by selectively treating, isolating, and retreating unstimulated areas along the vertical or horizontal wellbore.

Fracturing fluids and reactive fluids should be designed with knowledge of the specific shale mineralogy. The overall success of any shale play will include observation of the resource through its life cycle.

Vertical well stimulation

Current vertical stimulation designs feature:

- Four or five perforation sites, 2-4 ft long.

- 5 shots/ft (spf) and 60° phasing.

- Pump rates of 1-2 bbl/min per perf or 20 bbl/min per initiation site.

Volumes pumped are about 2,500 gal/ft, delivering 400 lb/ft of proppant.

In early phases of the life cycle, vertical wells are usually drilled and completed to help the operator characterize the reservoir. With the experience gained from drilling, fracturing, and producing the vertical well, more comprehensive life cycle phases 3 and 4 can be planned and performed profitably.

Horizontal well stimulation

Current horizontal stimulation designs typically include:

- Two to eight stages/horizontal wellbore.

- Two to four frac initiation sites/stage.

- 2-4 ft of perforations/site, with 6 spf, at 60° phasing.

- 20-30 bbl/min per frac site or 2-4 bbl/min per perforation.

- Volume average 1,800 gal/ft.

Horizontal completions

Horizontal well completions can be one of three types:

- Cased, cemented, multistage with composite plugs to separate frac stages.

- Multistage, with jetted sand and water delivered by coiled or jointed tubing to perforate zones.

- Mechanical bottomhole assembly.

The cased, cemented, multistage completion with composite plugs is the most commonly used type of horizontal completion in shale wells. Each stage is perforated, fracture-stimulated, and isolated with a packer or bridge plug, allowing the next stage to be treated. The plugs and packers act as a well “bottom” for fracturing pressure to build up against. This process is the most time-consuming, due to the cycle time for perforating, plug-setting, and drilling out plugs or packers. Use of composite plugs reduces drillout times drastically.

Jet-perforated, multistage completions eliminate the need to perforate or set plugs. This service is run on coiled or jointed tubing to the first-stage frac site; perforations and a tunnel are eroded by pumping through the tubing at a high differential pressure, using sand and water as the cutting stream. The fracture initiates and extends at the jet site; packers are not required because the jet velocity causes a pressure drop at the jet exit. The pressure drop pulls fluid from the annulus into the fracture. A more detailed discussion is provided in Part 1 (OGJ, Dec. 17, 2007, p. 39)

Mechanical bottomhole assembly (BHA)-type completions isolation packers have been run in horizontal shale wellbores as a new alternative to cementing and perforating. These systems are deployed as part of the production casing and provide mechanical isolation and selective injection sites that can be opened and, in some cases, closed manually.

Advancements have been made in the development of multistage frac-acid tools being applied in both openhole and cased-hole completions with hydraulic-set packers and sliding valves opened by pumping balls or shifting mechanical devices on jointed or coiled tubing.

Water fracs produce a complex network of narrow-aperture fractures that can be either induced from extensive shear-failures (like shattered safety glass) or created from dilation of pre-existing, incipient fractures or planes of weakness in the shale. The frac width must be 1.5± times the maximum grain diameter of the proppant to provide additional propping of the induced fractures.

Because the permeability of the matrix rock is usually ultralow (0.0001-0.001 md), except possibly near the wellbore, the fracture conductivity typically does not need to be high; 20-50 md-ft is sufficient conductivity through the fracture network. The exception would be with deeper wells with higher closure pressure and rock properties that would allow proppant embedment. In a few cases, we have not seen much correlation between production and proppant size. Many created fractures remain open and conductive even without proppant.

Many wells have been fractured proppant-free or with as little as 5,000 to 10,000 lb yet achieved commercial rates. Most Barnett shale well stimulations, however, are using proppant volumes in the range of hundreds of thousands of pounds. Although some operators question the value of proppants, with advancements in proppant design, correlating volume and type of proppant with actual production increases may be proved.

Adaptation and modification of current fracture models calibrated to real-time microsiesmic mapping are being used to help in the design of stimulation treatments.

Shale water-frac chemistry features application of friction reducers, surface-modification agents (SMA), microemulsions, deflocculants, and reactive fluids. The SMA helps minimize proppant settling, control production of fines, and enhance propped fracture conductivity. Microemulsion additives help remove water load and enhance recovery of fracturing liquids, resulting in significant uplift in recovery factors and estimated ultimate recovery (EUR).

Friction-reducer deflocculants are added to prevent the potential negative impact friction-reducer polymers can have when interacting with formation fines and liquid hydrocarbon. Conventional friction reducers can essentially form damaging, gunk-like material within the created fracture system that can seal off frac conductivity in the narrow-aperture fractures.

Refracturing

Vertical shale wells can see production increases of 30-80% from reperforating the original producing interval and pumping a job volume that is at least 25% larger than the previous frac.

There are two obstacles in refracturing horizontal: The initial frac sites must be somehow isolated, and new frac sites must be created in areas of unstimulated, horizontal wellbore. Various completion methods such as Halliburton’s SurgiFrac and mechanical completions with swellable packers eliminate the obstacles.

Shale-reactive fluids

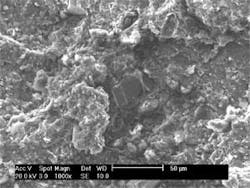

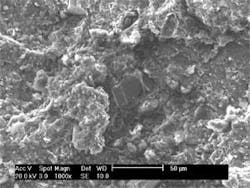

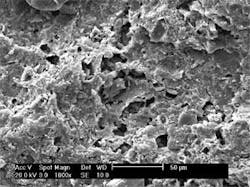

In general, shale is thought to be relatively nonreactive to low pH or acidic fluids because the clay, silt, and organic materials comprising the major components of shale formations exhibit insignificant bulk solubility in acid. Shale units are highly laminated, however, and contain acid-soluble minerals homogenized in the shale bulk matrix and natural fractures. X-ray diffraction analysis and scanning electron microscope images of shale samples show a great diversity and distribution of soluble material in the shale-producing unit.

The amount of gas produced by desorption is directly related to the amount of surface area exposed, and a shale-reactive fluid may increase the surface area of a newly created hydraulic fracture. Gas production from hydraulically fractured shale is believed to come from desorption and diffusivity from microporosity/fractures. Shale-reactive fluids may help remove acid-soluble minerals in the bulk shale as well as the mineral-filled fractures, thereby enhancing diffusivity of gas into the fracture network.

The use of reactive fluids is a relatively new concept in shale stimulation, evolving from the observation that shale lithologies contain distributed low levels of acid-reactive minerals. In experimental trials of the use of weak-acid reactive systems, the unexpected pressure-drops that occur when the reactive fluids contact the shale formation inspired treatments of 20,000 to 200,000 gal of reactive fluid through the frac water.

null

Initial production has been double that of treatments without reactive fluids included. Figs. 1 and 2 show shales before and after being exposed to reactive systems. Early field trials are showing excellent production improvement results.

Cementing shale wells

Constructing a suitable cement sheath around the horizontal section of a shale well is a key element in the process of successful fracture-stimulation of shale-gas zones. In recent exploration and production activity in Oklahoma’s Woodford shale, wells cemented with foamed cement produced an average of 23% more peak gas than wells cemented with conventional slurries.

Conventionally cemented wells did not provide adequate zonal isolation and allowed fracturing fluid to communicate along the horizontal casing. This condition caused targeted intervals to receive less than the designed volume of stimulation fluid and proppant.

Tensile strengths and mechanical properties of foamed cements make them ideal for zonal isolation in many hydraulic-fracturing operations. The low compressive strengths of these cements, however, concern some operators that have long considered compressive strength to be the leading indicator of cement-sheath integrity in high-pressure fracturing conditions.

Foamed cement’s relatively low compressive strength does not increase the risk for fracture initiation and propagation in the cement sheath during hydraulic-fracturing treatments. Stresses induced in the cement sheath by increased wellbore pressures during casing-pressure tests or fracture stimulation treatments are tensile in nature. The sheath’s capacity to withstand these stresses is predominantly determined by the cement’s mechanical properties (Young’s modulus and Poisson’s ratio) and tensile strength. Cement compressive strength is of minimal importance.3

The durability of foamed cement has been demonstrated repeatedly in Woodford shale hydraulic-fracturing operations, where foamed cement outperformed conventional cement in withstanding high internal casing pressures and high fluid hydrostatic pressures.

Two factors explain this performance:

- Mechanical properties of foamed cement allow it to withstand greater wellbore pressures than conventional cement.

- The ductile nature of foamed cement helps prevent the propagation of fractures in the cement sheath, helping ensure continued zonal isolation.

Well-cementing professionals believe that the ductile properties of the cement allow it to yield to injection pressure rather than shattering as is usually the case in high-density, more brittle cement. Also, the cement-invasion distance may be less because of improved fluid loss provided by the nitrogen bubbles.

Acid-soluble cement

Zonal isolation for limited-entry stimulation can be provided by acid-soluble cements (ASC).

Because conventional cements have a low solubility in acid, perforations can be difficult to break down and can inhibit fracture initiation and cause excess tortuosity during stimulation and production. Successful horizontal, limited-entry stimulation requires that all perforations are open and in communication with the formation and the designed perforation friction controls the fluid distribution along the wellbore.

Unopened perforations and near-wellbore friction resulting from tortuosity caused by the conventional cement can significantly alter the fluid distribution and decrease stimulation effectiveness. Conventional high-compressive strength cements with a typical acid solubility of less than 5% cannot be reliably removed so that each perforation is openly communicating with the formation.

Instead, acid-soluble cement can be used to provide zonal isolation without impeding stimulation and production. This type of cement has a fast solubility rate and is highly soluble (>90%) in acid-based stimulation fluids. ASC has physical properties much like conventional cement. It can be specifically formulated to provide the proper weight, fluid-loss, free water, compressive strengths, and pump times required for particular well conditions. Slurry densities and yield ratios can range from 13.0 lb/gal to 15.8 lb/gal and 3.55 cu ft/sk to 2.00 cu ft/sk, respectively (sk = sack). ASC can also be foamed if lower-density slurries are needed.

The easy removal of ASC material from the perforation cluster makes it especially suitable for limited-entry horizontal applications. The high-solubility allows the development of a larger communication area in the annulus immediately adjacent to the perforations while still providing excellent zonal isolation along the wellbore. This pocket that is dissolved around the casing at the clustered perforation point eliminates the tortuosity and fracture-entry pressure effects that could alter the planned limited-entry fluid distribution. Also, during production, the skin effects, reduced near-wellbore conductivity, and perforation-plugging problems associated with conventional cements are eliminated.

Cement process

The following well information is used to support an initial design for the foam-cementing process:

- Operator well plan for casing strings, drillbit sizes, casing sizes, drilling mud systems, and if the well is horizontal, a proposed directional survey.

- Depths and thickness of potential productive intervals and the fracture gradients and pore pressures of these intervals.

- Depths, thicknesses, and fracture gradients of potential lost-circulation intervals.

- Desired top of cement.

Design software aids in developing a cementing process tailored for the well, and the recommended cement slurries are laboratory tested for performance. During drilling, the cementing program is updated to reflect the influence of events that were not expected, for example, encountering an unanticipated pressure zone.

When well total depth is reached, initial well information is confirmed, drilling-mud reports are consulted, and drilling-mud and mixing-water samples are collected to be tested for compatibility with spacers.

Updated wellbore information is entered into the planning program to develop a final cementing-process design. Several aspects of the design are updated in the software program:

- Total depth.

- Casing depths.

- Size and grade of casing.

- Bit size used for horizontal section.

- Final directional survey.

- Last 3 or 4 days’ drilling-mud reports.

- Depths and fracture gradients of lost-circulation zones.

The cementing operation is monitored and controlled by operating company and service company representatives to maximize opportunities to make real-time changes to the procedure.

Other solutions

In areas where alternatives to foam cement may be preferred, recent advances in well cementing technology have made it possible to provide the option of nonfoamed cements with the enhanced mechanical properties and ductility required to cement shale wells that will be fracture stimulated. These cements can also be designed to expand. The required mechanical modification additives can be dry-blended with cement and mixed and pumped in the field using conventional equipment.

In practice, combinations of salts in cements and spacers and sodium silicates in preflushes in cementing fluids have provided a simple and proven means for managing shale instability during the cementing process when shale instability is considered to be an issue.

References

- Montgomery, Scott L., Jarvie, Daniel M., Bowker, Kent A., and Pollastro, Richard M., “Mississipian Barnett Shale, Fort Worth basin, north-central Texas: Gas-shale play with multi-trillion cubic foot potential,” AAPG Bull., Vol. 89, No. 2 (February, 2005), pp. 155-175.

- Blauch, M.E., Weida, D., Mullen, M., and McDaniel, B.W., “Matching Technical Solutions to the Lifecycle Phase is the Key to Developing a CBM Project,” SPE 75684, SPE Gas Technology Symposium, Calgary, Apr. 30-May 2, 2002.

- Deeg, W.F.J., “High Propagation Pressures in Transverse Hydraulic Fractures: Cause, Effect, and Remediation,” SPE 56598, SPE Annual Technical Conf. and Exhibition, Houston, Oct. 3-6, 1999.

The authors

Ron Hyden ([email protected]) has been group manager for stimulation at Halliburton since 2005, based in Houston. He joined the company 28 years ago, initially working in the East Texas and North Louisiana basins, and has since held positions in engineering, management, sales, and marketing. Hyden received a BS (1979) in chemical engineering from Texas A&M University and is a member of SPE.

Von Parkey ([email protected]) is technical manager for the US Midcontinent at Halliburton and works in Oklahoma City. He has been with the company for 26 years and has worked in various pumping services positions; field engineering, sales, technical team, management and in training at the Halliburton Energy Institute. Parkey holds a BS (1981) in agricultural engineering from Texas A&M University and is a member of SPE.

Bill Grieser ([email protected]) is an engineer and a member of the unconventional reservoir completions team at Halliburton Energy Services in Oklahoma City. He began his career with Halliburton in 1978 as a field engineer and has 29 years’ experience with fracture stimulation in Kansas, Colorado, Texas, and Oklahoma. Grieser is currently focused on completing horizontal wellbores and designing hydraulic fracture procedures in four Midcontinent shale plays (Barnett, Woodford, Caney, and Fayetteville). He earned a BS (1975) in nuclear engineering and BS (1978) in mechanical engineering from the Missouri School of Mines-Rolla. Grieser is a member of SPE, API, Texas Society of Professional Engineers, Oklahoma Society of Professional Engineers, and the National Society of Professional Engineers.

Rick Middaugh ([email protected]) is the southeastern US technical manager for Halliburton Energy Services, based in Carrollton, Tex. Since joining Halliburton in 1977, Middaugh has worked in operations, technology, sales, and management positions in the Michigan basin, Appalachian basin, and Midcontinent. He has also worked throughout the US as the business development manager and asset manager of Wellnite, a Halliburton joint venture involving the use of nitrogen and CO2 in the oil field. Middaugh holds a BS (1977) in agricultural engineering from West Virginia University and is registered petroleum engineer in West Virginia and Texas.

Glenda Wylie’s biography was published in Part 1, OGJ, Dec. 17, 2007, p. 39.

Makeup of productive shale formations

In general, a productive shale formation includes these characteristics:

- Zone thickness >100 ft.

- Well bounded and containing hydraulic fracture energy.

- Maturation in the gas window: Ro = 1.1 to 1.4.

- Good gas content >100 scf/ton.

- High total organic content (TOC) >3%.

- Low hydrogen content.

- Moderate clay content <40% with very low mixed-layer component.

- Brittle composition, as indicated by a low Poisson’s ratio and a high Young’s modulus.

- Combines rock fabric with reservoirs and lithology features that enhance gas producibility.

Shale technologies

Several production-enhancement processes are useful in shale-gas reservoirs:

- Prospect evaluation and core testing.

- Shale lithotyping to determine key characteristics of productive shale.

- Log data integration and analysis specific to shale.

- Designing and drilling the vertical and horizontal well for stimulation.

- Proppant size and loading considerations.

- Optimization and tailoring water-frac fluid chemistry to the shale.

- Remedial treatment processes for obtaining long-term sustained production.