Approach screens reservoir candidates for EOR

Rafael Sandrea

IPC Petroleum Consultants Inc.

Tulsa

Darshil Dharod

Indian Institute of Technology Kanpur, India

Enhanced oil recovery projects have moved down the industry's priority list given the oversupply of world crude oil and resulting low oil prices. This is, however, the right time for the industry to assess options for injecting new life into mature fields using EOR.

The authors developed a neuro-fuzzy approach that accounts for inherent uncertainties in survey data,1 including information quality, data resolution, and its relative scarcity over the broad spectrum of reservoir characteristics and various EOR methods.

The fuzzy tool brings data into sharper focus, improving assessments. The primary objective of the study discussed in this article was to develop a simpler decision model called the minimization of regrets (MMR) to screen potential reservoirs for EOR applications. MMR complements the fuzzy tool, minimizes limitations of field data, and provides visual information that simplifies the screening process.

IPC Petroleum Consultants estimates more than 1,500 world-class oil fields and thousands of smaller fields worldwide are prime EOR candidates (OGJ, Mar. 5, 2007, p. 34; OGJ, Mar. 12, 2007, p. 34). Each field has multiple reservoirs, and every reservoir is different.

Engineers seek to match the best available EOR option to subtle, yet critical variations in reservoirs. During the past 40 years, several screening methods were developed using technical and economic criteria to match the EOR method with the reservoir in question.2 3 Most screening methods are limited to scrutinizing reservoir information obtained from published survey data.

Recovery factors have been low across mature oil fields, with an estimated worldwide average of 22-25%. The North Sea has an average recovery factor nearing 50% while the US average is 40% (OGJ, Nov. 5, 2007, p. 44, and OGJ, Nov. 12, 2007, p. 39).

Estimated recovery rates at the country level change less than 1%/year in the countries mentioned. The estimates come from recognized institutions or government agencies.

EOR projects

Oil field development involves three phases. The primary phase of oil production depends on a reservoir's natural energy, which can stem from several individual mechanisms: liquid and rock expansion, solution gas, gas-cap expansion, gravity drainage, water influx, or combinations of these.

The most widespread natural drive mechanism is solution gas, wherein the gas dissolved in the oil provides the energy to expel it from the reservoir. This drive mechanism can provide a recovery efficiency of up to 20% of the in-place resource. About one-third of the world's oil fields have natural water drives that provide added recovery depending on the intensity of the water influx.

Stranded gas re-injection and waterflooding-secondary recovery or IOR-normally supplement primary or natural processes early in a field's life, with the objective of maintaining reservoir pressure and boosting oil recovery.

Tertiary or EOR methods applied at the end of the secondary phase attempt to sweep out as much of the remaining oil as possible. EOR methods are largely grouped as thermal, miscible, chemical, and biological. Some, like steam, have been around since the 1940s.

Statistics on EOR activity go unreported and have to be collected from open literature. OGJ's Worldwide EOR Surveys constituted the main source of the database used for this article (OGJ, May 5, 2014, p. 93).

An estimated 1,500 EOR projects occurred worldwide over the years for which records were kept, although many were pilot-scale projects, and others were terminated long ago.

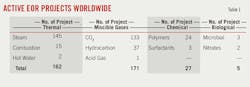

In devising a screening model, researchers analyzed 365 active projects covering 10 genres of EOR technology from 16 major oil-producing countries (Table 1).

Argentina, Egypt, Mexico, Netherlands, and the UK each had 1; Columbia, Norway, and Indonesia each had 2, India 3, Brazil 8, Germany 9, Trinidad 11, China 36, Canada 39, Venezuela 48, and the US 200.

Steam and miscible gas projects combined account for more than 86% of the total. Steam generally is associated with heavy oil (< 25° API gravity) reservoirs, while miscible gas injection methods predominate in light oil (> 25° API gravity) reservoirs.

Few current EOR projects use polymers and surfactants. Operators tried more than 200 projects each in the US for polymers and surfactants during the 1980s , but acceptance of chemical methods fell due to its eratic performance, sometimes in the same field.

The US has only two active field-scale surfactant projects, both of which started in 2007. Newport Energy LLC of Irvine, Calif., is pioneering a proprietary surfactant injection process known as advanced waterflooding (AWF).

Surfactant-AWF primarily complements ongoing water-injection projects post water-breakthrough. The process is cyclic (inject-soak-produce) and has been effective in both light and heavy oil reservoirs, including reservoirs with oil as low as 11° API gravity.

Other emerging AWFs use nitrates (Nitra-Gen LLC of Ochelata, Okla.) and low-salinity water (Statoil and BP PLC) to enhance standard water injection.

Only three pilot-scale microbial projects are under way worldwide. Nitrate waterfloods may become more common with the cost of nitrates dropping drastically since the development of onsite nitrogen generators.

Biological EOR methods' reservoir-temperature restrictions limit their use to formation depths less than 8,000 ft. If the reservoir has soured during water injection it generally is amenable to nitrate-AWF.

Successful EOR projects must overcome both technical and economic hurdles. The projects require high upfront investments while operators face a relatively long pay-out period. Another expense is continuous reservoir monitoring.

This article focuses principally on analyzing the limits of reservoir lithology and oil quality. Table 2 summarizes an EOR database. Reservoir quality was defined through six parameters: formation lithology, porosity, permeability, depth, oil gravity, and oil viscosity.

Formation lithology categories include sandstones, carbonates, and unconsolidated sands. Sandstones are the most common type of reservoir rock while carbonates host more than half of global hydrocarbon reserves. Their lithological dissimilarities, however, give rise to fundamentally different reservoir physics and require different reservoir management strategies.

Carbonates are complex because they have dual porosity and permeability systems: a 0.1-5 md matrix that stores the oil and slowly releases it to move through a highly permeable (> 1,000 md) fractured network in limestone containing many cavern-type holes.4

Such complexities can diminish a reservoir's drive and sweep efficiencies. Carbonates additionally adsorb injected EOR chemicals, which are more expensive than the oil being displaced. The clay effects of sandstones, meanwhile, are detrimental to IOR-EOR efficiencies.

Unconsolidated sands dominate in the Canadian and Orinoco oil sands, Caspian basin fields, and Indonesia, among other locations. Their high permeability, roughly 1 Darcy, avoids the reservoir stratification (vertical and horizontal permeability contrast or anisotropy) that strongly affects sweep efficiencies.

MMR

The authors developed MMR to help choose an appropriate EOR method for a particular oil reservoir based on the following reservoir parameters: depth, API gravity, viscosity, porosity, and permeability.

EOR's success in all lithologies excluded it from the list of considered parameters. MMR has become a widely accepted method for choosing between alternative EOR approaches.5 6

The "regret" component of minimization of regrets refers to a lost payoff or lost opportunity incurred when another available alternatives is chosen. The desired alternative is the one for which regrets are minimal.

The authors considered two alternative EOR methods, miscible gas and steam injection, which together account for nearly 9 of every 10 successful EOR projects. Frequency distributions of their respective reservoir parameters were prepared. Fuzzy logic was applied to account for survey-data uncertainty.

MMR treated each data point as a fuzzy number having a triangular distribution with a variation of ±15%. Resulting fuzzy frequency distributions were normalized to a range of 0-1. The accompanying figure shows the resulting distributions for the five reservoir parameters characteristic of miscible-gas EOR and steam-injection EOR.

Rock and oil parameters of the reservoir candidate to be screened are compared with the corresponding fuzzy-approach's frequency distributions. The model awards a payoff to each method for each parameter depending on the frequency range within which it falls. The figure shows the relative location of a reservoir candidate's parameters in the frequency distribution.

Subtracting the payoffs of each method from a maximum payoff of 1 created a regret matrix. Table 3 summarizes the results and shows an average regret of 0.80 for steam EOR vs. 0.44 for miscible EOR.

The figure represents a template for the general screening process. An engineer can plot data for any potential reservoir candidate on this template. The combination of fuzzy logic and MMR mitigates imprecisions in the survey data and enhances the decision-making process.

References

1. Sandrea, R. and Akanji, L., "A Fuzzy Approach to Screening Candidates for EOR", July 29, 2015, www.ipc66.com.

2. Steece, F.V., "Technical and Economic Criteria for Selecting Methods and Materials for Enhanced Oil Recovery," Interstate Oil Compact Commission Committee Bulletin, Vol. 26, No. 2, December 1984.

3. Alvarado, V. and Manrique, E., "Enhanced Oil Recovery: An Update Review," Energies, Vol. 14, No. 8, Aug. 27, 2011, pp. 1529-1575.

4. Manrique, E., Gurfinkel, M., and Muci, V., "EOR Field Experiences in Carbonate Reservoirs", International Energy Agency's Annual Workshop and Symposium on EOR, Stavanger, Sept. 5-8, 2004.

5. Loomes, G. and Sugden, R., "Regret Theory: An Alternative Theory of Rational Choice under Uncertainty," The Economic Journal, Vol. 92, No. 368, December 1982, pp. 805-824,

6. Bell, D.E., "Regret in Decision Making Under Uncertainty," Operations Research, Vol. 30, September-October 1982, pp. 961-981.

The authors

Rafael Sandrea ([email protected]) is president of IPC Petroleum Consultants Inc. of Tulsa. IPC is an international petroleum consulting firm specializing in oil and gas reserves appraisals and risk analysis for international upstream petroleum investments. He administers webinars and classes online and speaks worldwide on reserves, IOR/EOR, shale oil and gas assessment, and global oil and gas supply. He holds a PhD (1966) in petroleum engineering from Penn State University.

Darshil Dharod ([email protected]) is a PhD candidate at the Indian Institute of Technology (IIT) at Kanpur, India, where he has served as a research assistant. Previously, he conducted a research project with the Tohoku University in Japan and worked as a field engineer with Schlumberger Asia Services, Ltd. He holds a bachelors of technology degree (2015) in civil engineering from IIT.