Coiled-tubing fracturing effectively stimulates multiple coal seams

Coiled-tubing fracturing provides a way to stimulate multiple coal seams economically and effectively in the Black Warrior basin in Alabama, according to Joseph Legenza of Halliburton Energy Services, Tuscaloosa, Ala., in an account of the technology provided to Oil & Gas Journal.

He explained that the challenges for commercializing coalbed methane (CBM) wells in Alabama are to keep costs low and to stimulate effectively all the potential productive coal seams in a given wellbore.

Alabama coalbeds

Commercial coalbed methane production in Alabama started in the early 1980s. The 113 bcf/year of coalbed methane produced in the state represents about 28% of Alabama's total natural gas production.

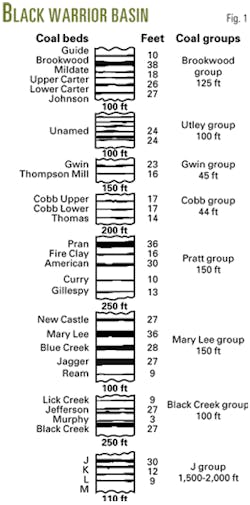

Most of this coalbed methane production is from the Black Warrior basin, which is in the northern part of the state. Four major coal groups (Black Creek, Mary Lee, Pratt, and Cobb) produce the methane (Fig. 1).

The Black Creek is at the greatest depth, and its coals lie in a 50-150 ft interval.

About 150-450 ft above the Black Creek is the Mary Lee group which has five coal seams over a 100-250 ft interval.

Next is the Pratt group, about 500 ft above the Mary Lee. It has highly variable seams in a 60-200 ft interval.

The shallowest coals are in the Cobb group, about 150-300 ft above the Pratt. The Cobb coals have to some extent been mined in the central portions of the Black Warrior basin.

Black Warrior basin fracturing

Legenza said that typical stimulation treatments in the Black Warrior basin include two to three stages of foam fracturing fluid that places 40/70-sized proppant.

He said the treatments involve:

Legenza explained that although the fracture design is based on high rates and limited entry perforating to place the desired volume of proppant in each seam, the production and after-pumping surveys have shown this method of stimulation to be largely ineffective in treating all the coal seams.

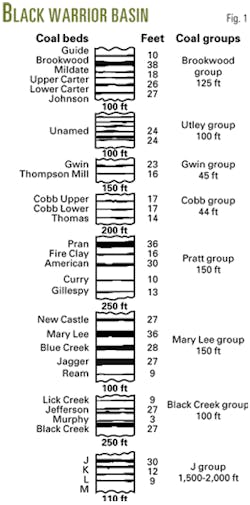

Conversely, he said coiled-tubing fracturing is proving to be economical and effective for stimulating multiple coal seams. He explained that by using coiled tubing as the conveyance method and a specialized bottomhole-assembly (BHA) to isolate each seam, it is possible effectively to place stimulation treatments into each individual seam (Fig. 2). The design enables the BHA to be repositioned without overflushing the fracture treatment.

Built-for-purpose coiled-tubing units enable rig up for coiled-tubing fracturing in as little as 20 min (Fig. 3). Photo courtesy of Halliburton Energy Services.

He said that considering each coal seam as an individual treatment allows maximum efficiencies in the design and placement of proppant. The jobs also benefit from built-for-purpose coiled tubing units that enable very fast rig up that help reduce job time and put wells on production quickly (Fig. 3).

Case history

R.G. Sanders, president of Black Warrior Methane Co., Tuscaloosa, Ala., during the case study, said the company used coiled-tubing fracturing successfully. In one example, Black Warrior Methane needed to stimulate production from three individual coal groups with several seams each in the J&M Land 8-9-300 well.

He said total thickness of all the seams (Mary Lee, Blue Creek, and Pratt) in the well is only 30 ft, but this thickness is distributed over 800 ft of wellbore. The well depth was 1,950 ft and he said the expected production rate after treatment was about 200 Mscfd.

Based on well conditions, he said, Black Warrior Methane selected coiled-tubing fracturing as the most efficient treatment method. In fact, he said no other solution would stimulate each coal seam within the Mary Lee and Black Creek coal groups cost effectively.

He described the treatment as involving:

Sanders said coiled-tubing fracturing could not be applied to the Pratt group because each perforated interval communicated with open perforations above and could not be isolated. The treatment for the Pratt group, therefore, was pumped down the 51/2-in. casing and included 70,000 lb of proppant.

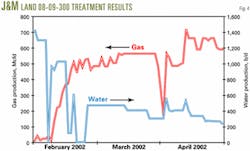

He said daily production before and after the treatment (Fig. 4) came in much better than expected. Instead of the anticipated 200 Mscfd, the well came in at 500 Mscfd against a 125-psi backpressure. He said the well currently produces 600 Mscfd.