Continuous pack-off inflow control device lowers water cut in trial offshore China

Feng Li

Xiaoping Li

Southwest Petroleum University

Chengdu, China

Bailin Pei

Songmei Zhang

Hailong Wang

Guojiang Feng

Jianchang Wu

Xiaoling Li

Anton Bailin Oilfield Technology Co. Ltd.

Beijing

Researchers lowered the water cut and increased oil production during a trial of a continuous pack-off inflow control device (CP+ICD) in an offshore horizontal well in 300 m of water in Liuhua oil field, eastern South China Sea.

CP + ICD technology was developed to resolve high water-production issues for horizontal wells. Previously, CP + ICD proved successful in the sandstone reservoirs of onshore northwestern China oil fields (OGJ, Oct. 3, 2016, p. 48 and OGJ, May 1, 2017, p. 52).

This article discusses the technology's first trial on a carbonate reservoir. It also marks the first offshore trial for CP + ICD.

Effective water control is a well-known problem in Liuhua field where industry reports cumulative oil production at 10% estimated OOIP. Operators often shut in Liuhua wells due to 99.5% basic sediment and water production.

The Cenozoic carbonate reservoir involves a one-porosity, two-permeability flow system characterized by fractures and minor faults. CP + ICD minimizes water production along a well's horizontal section because injected particles buffer water flow through the annulus.

CP + ICD differs from a swellable packer inflow control device (SP + ICD), which compartmentalizes a horizontal section into units. CP + ICD works in old wells unsuitable for mechanical packers and in poor-sealing wells having irregular wellbores or twisted casing.

Operators can restart shut-in wells because CP + ICD maximizes oil production while limiting water-production volumes after a water breakthrough. Heterogeneity of formations combined with reservoir fluid properties can cause an uneven flow or water coning toward the horizontal section.

The water-coning interval might be a small percentage of the entire wellbore, yet the overall water cut still can be high. Darcy's law establishes a strong correlation with the mobility ratio of in-situ water and oil.

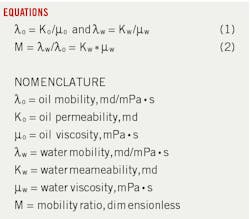

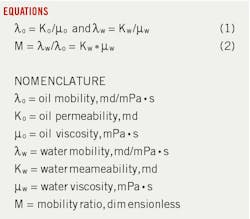

Equations 1-2 show the mobility ratio of water and oil in Liuhua reservoir. The water rate of the high-permeability zone is more than three times higher than the oil rate in low-permeability zones, assuming oil viscosity of 130 cp.

Fluid moves through the reservoir's fractures and faults to the wellbore. The ICD screen chokes water flow after water breakthrough.

Industry has used SP + ICD to remedy high-water production for more than 20 years, but it can be hard to isolate horizontal sections using mechanical packer installations. Some wellbores develop irregularities while drilling into unconsolidated reef limestone reservoirs. Consequently, a mechanical packer's seal malfunctions. Upon water breakthrough, oil production declines so drastically that operators shut in the wells.

The CP + ICD is self-adaptable to various wellbore conditions. Light, stable particles are injected into the annular space between the ICD screen and wellbore wall. The particles, which take the place of mechanical packers in a conventional ICD, also help control sand production.

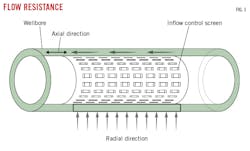

Fig. 1 shows how CP + ICD minimizes the axial flow relative to the radial flow. A 7-in. casing houses the 3.5-in. ICD screen. The ICD pipe is 10 m long with a 1-m junction.

Fig. 2 shows minor faults and mini fractures that provide direct communication with oil-bearing zones in Liuhua field. All wells experienced water breakthrough within weeks of coming on stream. Production stabilized after the water cut reached 90%.

Field trials

Earlier SP + ICD trials proved incapable of controlling water in Liuhua field's fracture-fault system. The SP + ICD and autonomous inflow control device (AICD) trials involved two wells with five swellable packers installed to divide a horizontal section into six units. A 99% water cut was recorded after 9 days of operation.

Reservoir characteristics indicated fractures and faults. Researchers detected wellbore irregularities. They also unsuccessfully tested chemical-based water-control technology.

A CP + ICD trial on Well A4H4 filled the 575-m lateral with CP particles. The trial was successful without engineers having to locate water-breakthrough points, fractures, and faults.

Well A4H4 was shut in during December 2015 after producing 99.5% basic sediment and water (BS&W). Fig. 3 shows the CP + ICD well completion with an 8 ½-in. open hole. Permeability was wide ranging, averaging 300 md. The oil had 130 cp viscosity.

Well A4H4 demonstrated water coning. The water cut reached over 90% within weeks of water breakthrough. Production dropped dramatically with water accounting for most of the produced fluid, making the well economically unfeasible.

The table shows a direct comparison of data from before and after the CP + ICD trial, indicating improved oil production and lower water production in 4 weeks. But the direct comparison could be misleading given altered operational circumstances. Part of the oil rate might result from additional liquid production. Other operating concerns include extra water disposal expenses or the need to reduce liquid production from other wells given constrained Liuhua oil-processing capability.

Researchers also indirectly compared production data through indexes. The water production index slid to around 14% of baseline data before the trial because the ICD screen imposed an additional drawdown to reduce water in the breakthrough unit. The oil-production index reacted similarly although not as dramatically. The oil index number was about half the baseline data number.

Dimensionless water-oil ratio (WOR) post-trial was down 78% overall compared with WOR pretrial data. If the same liquid production rate can be maintained, oil production could increase by 2.6 times, although production started to decline following the trial.

Acknowledgment

The authors would like to thank the collaborative efforts of CNOOC Shenzhen, Southwest Petroleum University, and Anton Bailin Oilfield Co. Ltd. Special thanks to CNOOC for sharing data and permission to publish the results.

Bibliography

Al-Khelaiwi, F., and Davies, D., "Inflow Control Devices: Application and Value Quantification of a Developing Technology," Society of Petroleum Engineers (SPE) International Oil Conference and Exhibition, Veracruz, Mexico, June 27-30, 2007.

Ellis, T., Erkal, A., Jokela, T., Kvernstuen, S., Leung, E., Moen, T., Porturas, F., Skillingstad, T., Vorkinn, P., and Raffn, A., "Inflow Control Devices: Raising Profiles," Oilfield Review Winter, December 2009, Vol. 21, No. 4, pp. 30-37.

Lee, B., Fassam, F, Galimzyanov, A., Faizal, S., and Vicario, R., "ICD Evaluation Study Using Numerous PLT Runs to Optimize Design Practice and Maximize ICD Value," International Petroleum Technology Conference, Kuala Lumpur, Dec. 10-12, 2014.

Okwananke, A., Isehunwa S., Adeosun T., and Adeboye Y., "Water Cresting Predictions in Horizontal Oil Wells," Advances in Sustainable Petroleum Engineering Science Journal, September 2012, Vol. 4, No. 3, pp 109-124.

Permadi, P., Lee, R., and Kartoatmodjo, R., "Behavior of Water Cresting Under Horizontal Wells," SPE Annual Technical Conference and Exhibition, Dallas, Tex., Oct. 22-25, 1995.

Zeng, Q.S., Wang, Z.M., and Yang, G., "Comparative Study on Passive Inflow Control Devices by Numerical Simulation," Tech Science Press S.L., Vol. 9, No. 3, May 2013, pp. 169-180.

Youl, K., Suhana, W., Regulacion, R., and Jorgensen, T., "Passive Inflow Control Devices and Swellable Packers Control Water Production in Fractured Carbonate Reservoir: A Comparison with Slotted Liner Completions," SPE-IADC Drilling and Exhibition, Amsterdam, Mar. 1-3, 2011.

Sun, X., and Bai,, B., "Comprehensive Review of Water Shutoff Methods for Horizontal Wells," Petroleum Exploration and Development, December 2017, Vol. 44, No. 6, pp. 1022-1029.

The authors

Feng Li ([email protected]) is an upstream department head of CNOOC Shenzhen, managing the oil and gas production in the East Part Region, South China Sea. He is pursuing a PhD with State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, Southwest Petroleum University, Chendgu, China.

Xiaoping Li ([email protected]) is a professor at Southwest Petroleum University. He holds a PhD in petroleum engineering from Southwest Petroleum University. He specializes in reservoir engineering and well test analysis.

Bailin Pei ([email protected]) is an associate professor in the petroleum engineering department at China University of Petroleum in Beijing. He holds a BS and MS in petroleum engineering from Southwest Petroleum University and a PhD in hydromechanics from the University of Science and Technology of China, Hefei. His research covers horizontal well water control, sand prevention, and inflow control devices.

Songmei Zhang ([email protected]) is a senior reservoir engineer at Anton Bailin Oilfield Technology specializing in water-control issues and sand prevention. Zhang graduated from China University of Petroleum in Beijing with an MS (2004) in petroleum engineering.

Hailong Wang ([email protected]) is a reservoir engineer at Anton Bailin Oilfield Technology. He graduated from China University of Petroleum in Beijing with a BS (2011) in petroleum engineering.

Guojiang Feng ([email protected]) is a mechanical engineer at Anton Bailin Oilfield Technology. He has 17 years oil and gas experience. He graduated from Harbin University of Science and Technology, China, with a BS (2000) in mechanical engineering.

Jianchang Wu ([email protected]) has worked for Anton Bailin Oilfield Technology since 2013. He started his oil and gas career in 2006, focusing on well-screen design. He received a BS (1995) in manufacturing engineering from the North China Institute of Aerospace Engineering, Langfang.

Xiaoling Li ([email protected]) is an experienced reservoir engineer, having worked in both China and Australia. She completed her BS in petroleum engineering (1991) from Petroleum University (East China) and is pursuing a PhD with the University of Queensland, Brisbane, Australia.