Study assesses materials to minimize mud losses in Algeria's Hassi Messaoud field

Nadia Haddoum

Sonatrach Algiers, Algeria

Ahmed Hadjadj

Abdelbaki Benmounah

University of Boumerdes Boumerdes, Algeria

Diesel, bentonite, and cement are affordable and plentiful in Algeria but operators are not using them to their full potential as lost-circulation materials (LCM). Laboratory testing and field testing sought to improve possible additives for drilling fluids to prevent circulation loss in fractured formations and caverns in supergiant Hassi Messaoud field. Several complex new plugs are available, and clay minerals behave, at least initially, as a beneficial rheological additive in drilling muds.

Mud loss is the main problem encountered during drilling in Hassi Messaoud, where circulation control was reported in about 85% of more than 1,200 wells drilled to date. The volume of mud lost varies from as little as 66 cu m in one well to 6,149 cu m in another. The authors tested different slurry formulations (plugs) using diesel oil, clays, cement, and polymers.

Testing showed the composition and concentration of certain drilling fluid additives influenced their penetration characteristics and compressive strength. Increased concentration led to decreased penetration, which improved plug consistency. Even with a high-clay concentration, a plug could remain plastic and take the shape of fractures. Results showed mud losses varied widely depending on specific formulas.

The LCM strength increased over time after placement of certain cement slurries, such as a mixture of hydraulic cement, diesel oil, bentonite, and mud.

Almost anything can be used to achieve a plug in a porous formation, given enough pressure, proper particle size, and suitable properties. The question is whether the plug will remain in place under the stresses of rotation, vibration, and pressure (Fig. 1) Lost-circulation treatments typically push great volumes of LCM into the formation. The most desirable effect from drilling fluid additives is a shallow, permanent bridge that stops fluid losses yet responds to perforating for future production in the zone.

LCMs have improved, but lost circulation still poses a problem for the drilling industry (OGJ, Apr. 1, 1963, pp. 105-110).1 2 3 4

Clay hydration varies

Hydration capacity of the montmorillonite mineral group is known for its elevated swelling power and colloidal qualities. Bentonite (Fig. 2) comes from decomposed volcanic material affected by alkali or acidic water. Raw bentonite is processed by adding sodium carbonate and vinyl alcohol, grinding it to 10 mm diameter, drying to 5% humidity, milling, classifying, and packaging into 50 kg bags for drilling fluids.

Researchers used prepared samples made with distilled water for different bentonite concentrations. Samples were prepared in tanks, agitated for 20 min, and the fluid left to rest 1 hr before testing.

Bentonite reacts with salts of aliphatic amine quaternary to create organoclay. In studying LCM, different organophilic concentrations were mixed with diesel oil.

Hysteresis loop tests measured thixotropy. A constant-rate "low-shear 40" viscometer was used to obtain measurements. These experiments were performed with a controlled-rate rheometer. The most common tests involved changes of shear rates or shear stresses.

Increasing the applied stress to a prefixed maximum value and decreasing it to 0 provided the loading and unloading needed to study the hysteresis loops. Testing demonstrated the hysteresis loops' existence, indicating thixotropy. The thixotropic loop's area increases with bentonite content.

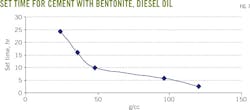

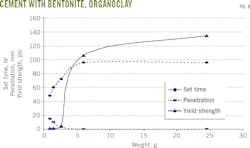

Figs. 3-4a show how different bentonite suspensions yielded different shear stress measurements with varying shear rates applied. Rheological characteristics changed with increased bentonite and organoclay concentration.

The clays, known for their crystalline structures, exhibit a leaflet stacking shape, allowing insertion of water and oil molecules, influencing spacing, and enabling rheological characteristics. Organoclay suspension samples were measured for shear stresses from the different applied shear rates (Figs. 4b-5).

Analysis of flow curves demonstrated three characteristic phases for clay suspensions:

• At the beginning of shearing, the mud mixture exhibits a solid behavior. The stress is not sufficient to create a flow.

• For low-rate gradients (<10 sec-1), beyond the yield point, the sample quickly behaves as a fluid. The rate gradient increases linearly with the stress. Apparent viscosity decreases quickly.

The flow curves' measured values of shear stress increased progressively with time and temperature. Apparent viscosity increased with time, caused by a swelling of aggregate particles.

Water balanced the high concentration of ions present between particles, creating osmotic pressure. The rheological characteristics of different clay concentrations were studied to determine plastic behavior, which influences a plug's swelling and squeezing abilities.

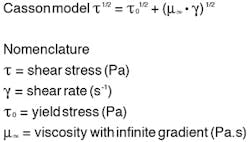

The equation shows the rheological model used (see accompanying box).

Researchers selected only the Casson model because it provided the best approximation between theoretical and experimental curves. Some suspensions presented a highly thixotropic character at high concentrations, leading to modified mechanical behavior stemming from the physicochemical properties of the clay's shaly particles.

Combating lost circulation

Lost circulation can result from natural fractures or the drilling mud's weight.

Hassi Messaoud field, 900 km southeast of Algiers, is a flattened anticline on the north of the El-Biod-Hassi Messaoud elevation formed by a sequence of horsts and grabens contained by faults. The field was discovered in 1956. The reservoir consists of three major formations: R1, R2, and R3 from top to bottom. R1 was divided into 2 subformations, R1 (top) and Ra (bottom).

Hassi Messaoud has estimated ultimate recovery of 9 billion bbl of 43° gravity oil. It produces from a 900-ft oil column in a Cambrian sandstone reservoir at 11,000 ft in a 1,300 sq km productive area.

A statistical study of Hassi Messaoud showed lost circulations occurring generally along the Trias Argilo Greseux (TAG). Each well needs at least one cement plug to seal the formation.

Soft plugs combat severe mud losses in natural and induced fractures. This article studied two types of plugs:

• Plastic plugs are soft and develop high-gel strength rapidly when first mixed, but do not become rigid when set. There are three plastic-plug systems: direct, inverse, and mixed.

• Hard plugs have soft-plug characteristics when first mixed, but they become rigid.

Experiments used a plug test measured with a standard consistometer, cement slurries measured with a high pressure-high temperature (HPHT) consistometer, and plugs of mud plus diesel oil and bentonite (DOB) or mud plus diesel oil-bentonite-cement (DOBC).

The standard consistometer estimated prepared plugs' consistence qualitatively and quantitatively.

One test used a cylinder filled to the top with a plug formula. The top of the plug and the end of needle were allowed to touch without any initial penetration. With no initial velocity, the needle was released to penetrate the plug. When the needle stopped, the distance was estimated.

The higher the clay concentration used, the less penetration resulted. Plugs made of different ingredients and concentrations were tested. There was no friction between the mobile and fixed parts of the apparatus.

Fig. 6 shows the results of tests on plastic plugs and Figs. 7-8 show the results of tests on hard plugs.

An HPHT consistometer measured the thickening time of different cement slurries along the cementing string and across different formations. This apparatus can operate at more than 1470° C. and 14,000 psi.

Measurements plotted from 0 to 100 units of consistency (UC) on a chart divided into 10 sections created 10 units of consistency.

HPHT consistometer readings helped establish 40 UC as the upper limit of cement slurry pumpability. Beyond 40 UC, the slurry starts thickening.

Testing used different concentrations for the three plastic systems (direct system, inverse system, mix system) and the hard plug (DBOC). Results showed the mixture's behavior from the beginning of integration to when the component was mixed completely (100 UC).

Researchers prepared plugs under standard temperature and pressure conditions. The clay's reaction with the liquid (oil for organoclay and water for bentonite) was spontaneous.

Bentonite added directly to water did not behave the same as bentonite added to diesel and water. When added only to water, just the bentonite's external particles swelled. But when put in diesel and then water, all particles reacted.

The clay's swelling and the homogenous dispersion of particles in the liquid phase explained rapid plug setting.

When bentonite was added to water, or organoclay to diesel, the external particles reacted and formed a plug that separated the liquid phase and clay particles.

A pilot well drilled using slurries described in this article performed field tests to reduce lost circulation and reduce drilling costs. The well was drilled to 3,500 m. Bentonite was an effective LCM for the pilot well (see accompanying table). Because it does not swell appreciably in oil, Bentonite can travel downhole with drilling fluids. Soft plugs especially were suited for sealing induced and small natural fractures.

When the mixture contacts formation water, hydrophobic clay hydrates very rapidly, expelling the oil phase and resulting in a highly consistent mixture with a natural angle of slope beyond 90°. The clay can easily block cracks and fractures.

Simulated consistency tests under HPHT conditions (70° C., 480 bar), revealed the series of fluctuations caused by the progressive formation of aggregates which transformed into a mixture. The consistency index increased with higher clay concentrations.

Shaly suspensions tested exhibited high thixotropic behavior as shale content increased. The rheograms' shape shows the behavior of drilling fluid additives as associated with physicochemical properties of the shaly particles. The test suspensions' yield point was a function of clay concentration and rest time.

References

1. Bohloli, B., and Pater, D., "Experimental study on hydraulic fracturing of soft rocks: Influence of fluid rheology and confining stress," Journal of Petroleum Science and Engineering, Vol. 53, No. 1-2, August 2006, pp. 1-12.

2. Madsen, F. T. and Muller-Vonmoos, M., "The Swelling Behavior of Clays," Applied Clay Science, Vol. 4, No. 2, June 1989, pp. 143-156.

3. Ozdemirtas, M., Babadagli, T., and Kuru, E., "Experimental and numerical investigations of borehole ballooning in rough fractures," SPE Drilling & Completion, Vol. 24, No. 2, February 2009, pp. 256-265.

4. Kherfellah, N., Ait-Salem, H., Bekkour, K., and Benhadid, S., "A Sedimental Approach for an Optimal Resolution of Drilling Mud Losses," Oil & Gas Science and Technology, Vol. 57, No. 6, December 2002, pp. 631-635.

The authors

Nadia Haddoum (([email protected]) has worked at Sonatrach as a drilling engineer specialist since 1998. Previously, she taught at Algiers University where she obtained her BS (1993) and MA (1998), both in fluid mechanics. She speaks frequently at oil and gas conferences worldwide and has written many papers about improved drilling concepts.

Ahmed Hadjadj ([email protected]) is an associate professor at the University of Boumerdes, Algeria, hydrocarbons and chemistry department and president of the reservoir department's scientific counsel. Previously, he was a Sonatrach executive project manager and held research positions in Canada and France. He holds a PhD (1996) in mechanical engineering obtained from Franche Compte University, Besancon, France, and an MS from the University of Nice Sophia Antipolis, France.

Abdelbaki Benmounah ([email protected]) is a professor at the University of Boumerdes, Algeria, department of materials engineering. He is chairman of the scientific council of the faculty of engineering sciences. Since 2014, he has directed a research team on rheology of dispersed media and cementitious materials. He obtained his BS (1977) in drilling engineering at Hydocarbons Institute, Boumerdes, Algeria, and a PhD (1998) in drilling engineering at Gubkin Russian State Oil and Gas University.