On-site fuel conversion powers frac fleets

Jim Haider

GTUIT LLC

Billings, Mont.

GTUIT LLC introduced direct fuel conversion (DFC) technology to power frac spreads using field gas at location. Detailed analysis of fracture treatments on three pads showed that the technology replaced an average of about 300,000 gal/pad of diesel with treated methane-ethane. Over 125 jobs have been performed to date with frac spreads using Tier 2 and Tier 4 dual-fuel engines, turbine generators, and all-gas reciprocating engines.

NGL cannot be used in dual fuel or all-gas engines, and DFC separates NGL from the fuel stream and turns it into a revenue stream to reduce net delivered fuel cost.

DFC

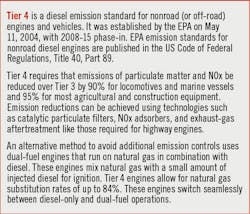

Historically, drilling rigs and pressure pumpers have powered rigs and pumps with diesel engines. Depending on depth and basin, fuel consumption per fracture treatment ranges from 250,000 to 350,000 gal. A push to use cleaner burning and less expensive natural gas pushed the industry to develop rigs and frac fleets which run primarily on natural gas. The latest Tier 4 dual-fuel engine technology can substitute upwards of 85% natural gas in place of diesel and still achieve required engine performance while meeting US Environmental Protection Agency Tier 4 emissions standards.

Retrofit kits have also been developed to convert earlier Tier 2 diesel engines to substitute some portion of gas for diesel, but at a lower replacement efficiency than Tier 4 engines. To power drilling rigs and frac fleets with gas, pressure pumpers and drillers have relied on gas sources trucked to frac sites from regional processing in the form of compressed natural gas (CNG) or LNG.

Many frac sites have gas gathering pipelines either at or near location. Unfortunately, raw associated gas is generally too rich to be used directly for substitution in any gas capable engine. Rich or “hot” gas has propane (C3) and heavier hydrocarbons (C3+) as part of the raw gas composition. Inconsistent fuel quality with heavier components causes derated engine performance, engine knocking, degradation, and increased maintenance, resulting in increased downtime on location and heavy maintenance costs for frac fleets or drilling rigs.

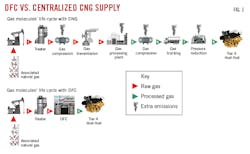

CNG is often utilized in dual-fuel engines, however obtaining useable CNG on site requires multiple steps, each of which adds costs and increases overall emissions. DFC conditions field gas on location and eliminates most of these steps (Fig. 1).

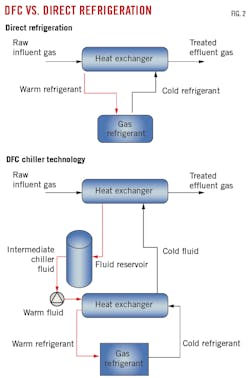

DFC uses chiller technology specifically designed for associated gas. It decouples the refrigeration process from the varying natural gas compositions at the inlet to provide a constant temperature for natural gas separation (Fig. 2). Direct refrigeration mechanical units cool the treatment heat exchanger using refrigerant gas. By contrast, DCF utilizes a tank of intermediary cold liquid with excess capacity to cool raw gas in the treatment heat exchanger. The system acts like a cold-storage battery, maintaining treatment temperature and reacting quickly to varying inlet conditions.

This constant-temperature operation, in combination with constant pressure, provides a consistent fuel-gas heating value. Heating value describes the energy content of a specific volume of natural gas (e.g., btu/scf) and is important for gas-consuming equipment. It determines the amount of gas that must be consumed to provide a specific amount of energy for the required end-use. It is also an indicator of gas quality because gas with greater heating value or higher btu content will frequently have more long-chain or heavy hydrocarbons which will disrupt engines, prevent diesel substitution, or cause damage.

Inlet, effluent gas composition

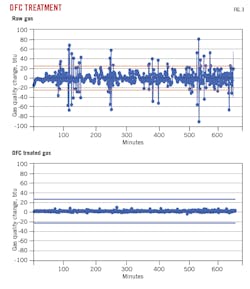

Gas coming directly as a byproduct of oil production does not have compositional controls and may vary from day-to-night temperature excursions or weather changes. Direct refrigeration or Joule-Thomson systems cannot react quickly to inlet changes, resulting in inconsistent effluent gas composition. DFC’s intermediary liquid cools the heat exchanger to maintain uniform treatment temperature. Fig. 3 shows gas quality changes in btu over the course of 10 hrs of operation in a hydraulic fracture application. Inlet gas quality varied on average by about 25 btu during the operation with periodic excursions up to 60 btu. By contrast, gas effluent from DFC varied about 7 btu on average over the same operation with periodic excursions of about 10 btu.

High-btu gas contains C3+ in gaseous phase which is harmful to an engine yet is valuable monetarily. Once gas processes through the DFC system, C3+ NGLs are condensed and separated. By recovering those liquids after removal, the operator effectively utilizes the methane and ethane in the frac spread while retaining the value of the NGL.

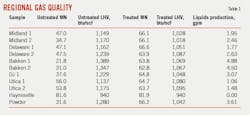

Table 1 shows regional gas quality and potential liquid production in large unconventional basins in the US. Included in the table are untreated vs treated methane numbers (MN) and lower heating value (LHV). MN is a measure of the resistance of natural gas to detonation when burned as a motor fuel in an engine. Pure methane is assigned an MN of 100 and pure hydrogen is assigned an MN of zero. Natural gas having an MN of 80, for example, would have detonation properties similar to a mixture consisting of 80 vol % methane and 20 vol % hydrogen.

DFC field operations

Typical frac spreads in Permian and Delaware basins have 15-20 frac pumps which require about 3 MMcfd of fuel gas. Each 1 MMcfd DFC processing system typically supplies enough gas for diesel substitution in six dual-fuel frac pumps. Water that is removed from the raw gas is sent to on-site wastewater disposal systems. Units can be on or off-site and have supplied gas up to a mile away from the pad location.

Units are modular and come in 0.5 or 1 MMscfd increments for low-pressure source gas and 2 or 4 MMscfd units for high-pressure source gas. The low-pressure systems operate with inlet gas pressure as low as 15 psig. The equipment will boost pressure to 140 psig for the frac spread while also removing propane and heavier components. DFC high-pressure equipment operates with inlet gas from 800-1,350 psig and provides a consistent pressure-treated fuel at 130-240 psig discharge pressure, depending upon the engine to be fueled. Both low-pressure and high-pressure equipment can be added and subtracted to match flow rates required by hydraulic fracturing spreads or drilling rigs.

Case histories

In August 2021, GTUIT provided DFC to three frac spreads in the Big Springs area, Midland basin. Number of wells on pad and number of stages per well varied between cases. The DFC fleet consisted of three 53-ft trailers with combined gas-processing capacity of 3 MMscfd (Fig. 4). The frac fleet required about 15 dual-fuel powered pumps. Table 2 lists the number of wells on pad, job duration, diesel volume substituted, and recovered NGL volumes.

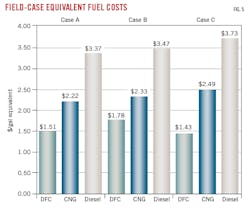

Equivalent fuel cost comparisons in diesel gallons equivalent (DGE) are shown in Fig. 5. DGE is the total processed fuel-ticket price with revenue from NGLs deducted. Diesel and CNG prices were obtained from average spot market prices during the time of service. In general, DFC DGE cost was about half that of diesel over the three cases.

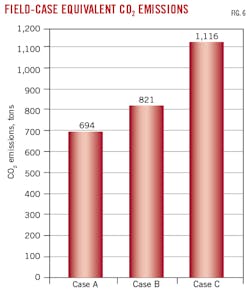

An estimated 694 tons of CO2 were saved in Case A based solely on diesel substitution by DFC (Fig. 6). Using the same methodology, an 821-ton CO2 savings is estimated for Case B and 1,116 tons for Case C.

DFC also minimized diesel or CNG truck traffic, improving road safety and eliminating CO2 from truck emissions. The CO2 savings reported in Table 2 do not include elimination of truck traffic. For example, in Case A, an estimated 29 diesel fuel supply trucks or 60 CNG trucks were eliminated for the fracture treatments.

The author

Jim Haider ([email protected]) is chief technology officer at GTUIT in Billings, Mont. He has a BS (1989) in mechanical engineering at Colorado State University and is a licensed Professional Mechanical Engineer. He is a member of the Gas Processors Association, American Society of Mechanical Engineers, Montana Petroleum Association, and the North Dakota Petroleum Council.