Expandable liners isolate sloughing zones in directional, horizontal wells

Several Russian oil field case histories have demonstrated that expandable-profile tubulars or pipes have proven to be an effective way to control formation caving and sloughing problems in directional and horizontal wells.

Wellbore stability

When drilling through incompetent formations, operators face drilling operational problems that come with sloughing and cavings within specific zones. Finding effective solutions to the sloughing reduces well costs, increases labor productivity, and improves overall drilling results.

Research investigations as well as local and international experience has indicated that the factors governing cavings and wellbore-stability problems within clay formations are summarized within the following groups:

- Geological factors that depend on geologic structure and physical stress-strain properties of rocks.

- Technical drilling factors that relate to the drilling equipment, materials, and technology applied, drilling-problem control, and drilling operational considerations.

Geological factors might also include tectonic features, clay swelling and soaking from water ingress, abnormal capillary pressure that leads to clay instability, absence of mud cake to control clay exposure to mud filtrate, stressed state of clay formations after penetration, and osmotic phenomena.

Factors related to drilling operations might include pressure drop during trips or swab pressure, upward flow velocity, drilling fluid structural-strength properties, drilling mode, delayed stabilization of incompetent rocks.

Control methods

As researchers investigate the reasons for clay-formation stability problems and causes of wellbore stability issues, the answers indicate that drillers must either control the drilling mud properties or isolate the wellbore stability problem mechanically.

To affect wellbore stability through the drilling mud, the drilling engineer must decrease the mud-filtrate flow through the mud cake to the argillaceous rock, changing the mud's water-loss properties, or use nonaqueous or hydrocarbon-based drilling fluids.

The drilling engineer must ensure sufficient or appropriate mud weight to ensure sufficient back pressure on the wellbore and formations. Cavings within claystone intervals may still occur, however, even if operators work hard to control mud weight, minimize the mud's water loss, or use nonaqueous drilling fluids.

Enlarged-hole cementing

In the Romashkinskoye oil field, caving generally occurs in the Ufimian stage, and Vereiskian, Uglenosny, and Kynovskian horizons.

The operator OAO Tatneft has accumulated a wide hands-on experience on caving control methods backed with scientific research.

The Vereiskian and Uglenosny horizons require similar methods for controlling the caving problem. After penetrating these beds, drilling operations continue until reaching the first hole-conditioning depth. Crews then cement the enlarged-hole section, drill out the cement plug, and continue drilling the well deeper. If required, the crews repeat the hole conditioning and cementing.

If drilling engineers expect to encounter water entry within the Namurian stage or lost circulation in the Tournaisian stage, drilling stops and the well cemented as required after penetrating the Vereiskian or the Uglenosny horizon, respectively.

Water influx from below the Namurian stage or lost circulation within the Tournaisian stage will prevent the crews from obtaining quality cement plugs.

The company does not recommend attempting to cement enlarged wellbores or caverns after the rig has drilled into the producing formation. Cement would invade the reservoir and destroy permeability and limit production capability.

The drillstring occasionally becomes stuck after the drillbit drills through hardened cement, following cementing operations to stabilize a wellbore that became enlarged from cavings and sloughing. The hardened cement can break causing the drillstring to become stuck.

Expandable liners

By isolating problem intervals immediately after drilling through them, expandable liners have proven more reliable than cementing to resolve drillstring sticking problems within caving zones.

The OAO Tatneft's Leninogorsk drilling department faced problems when drilling Well No. 9399 caused by sloughing in the Vereiskian horizon in the interval 844-853 m. The operator attempted cementing with no success.

Crews cased off the sloughing interval with a 20-m long profile liner, known as type OLKS-216, without loss of wellbore diameter. The rig continued drilling the well to the required completion depth without problems (Fig. 1).

The company drilled Well No. 28852 to the projected depth. Because of violent sloughing and caving, however, logging tools could not pass the interval 1,228-46 m. Crews sealed off the problem zone with a 28-m long section of OLKS-216U type expandable-profile liner (Fig. 1).

Inclined well

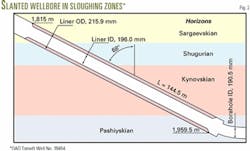

In the Romashkinskoye oil field, the claystones of the Kynovskian horizon cause the most serious caving and well stability problems. Engineers and geologists attribute this to the structural features of this very thick claystone.

Caving and sloughing-control issues become particularly acute when wellbores penetrate the Kynovskian horizon at angles of 65-69°, which is necessary for horizontal wells. Part of the borehole wall becomes a "roof" that experiences intense sloughing.

The longer contact time between the drilling mud and formation during the longer drilling operations, contribute greatly to the problem.

To ensure trouble-free drilling of the first horizontal wells, OAO Tatneft crews used 245-mm intermediate casing strings 1,800-2,000-m long and landed in the Pashiyskian horizon top, which is the pay zone. The additional casing string increased well cost and drilling time significantly.

Tatar Oil Research and Design Institute (TatNIPIneft) developed the technology to isolate the Kynovskian horizon with expandable-profile liners.

The researchers used the profile liner, type OLKS-216U, for the purpose. The liner did not require hole enlargement but the well diameter was reduced partially.

Since the horizontal-well design required penetration of the Kynovskian horizon at an angle of 65-69°, engineers could not use existing profile liners. Researchers developed a special type of profile liner made of a removable shoe and a threadless connecting head.

The company successfully tested the technology in Well No. 39454 of Zapadno-Leninogorskaya area, to case off incompetent rocks within the Shugurian and Kynovskian horizons in the interval 1,820-1,954 m (Fig. 2). The rig drilled the interval with a 215.9-mm bit at an angle of 68°.

Before running the profile liner, crews conditioned the wellbore in the permeable interval of the Namurian, Lower Famennian, and the set interval for the profile liner of 1,810-1,965 m.

The rig conditioned the intervals with a bottomhole assembly that included a 215.9-mm drillbit, 300-mm long sub, 214-mm calibrator (type 12KSI), downhole motor (type DZ-172), and 127-mm drill pipe.

Crews degreased and applied bitumen mastic to the surface of the first and last profile pipes. The rig ran the 144.5-m long profile liner into the interval 1,815-1,959.5 m and straightened the pipes with 10 MPa (1,450 psi) applied to the drill pipe. The RSh-190 and RSh-196 expanders, run with a downhole motor (type DZ-172), expanded the profile liner.

The rig continued drilling operations for the remainder of the horizontal well, with a 190.5-mm drillbit in the bottomhole assembly and with a downhole motor (type DZ-172).

The drilling operations prior to landing and cementing the production casing took 880 hr and 18 trips. Crews encountered no problems related to the profile liner. The well serves as a good example of how the use of profile liners to replace intermediate casings, intended to case off sloughing formations, can simplify a horizontal-well design.

Horizontal well

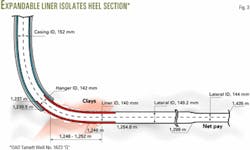

Well No. 1623 "G" of Bastrykskoye oil field presents another horizontal well design example.

After the rig had drilled the horizontal wellbore, the drilling company faced the caving problems that led to tools sticking and jamming. Production of the well was impossible.

Crews drilled the well, according to the drilling program, with a 215.9-mm drillbit to the depth 1,239.5-m and ran 168-mm casing string. The rig continued drilling the horizontal lateral with 149.2-mm drillbit to 1,298 m and then completing the section with 144-mm drillbit to 1,435 m.

Well logs identified sloughing clays in the interval 1,248-1,252 m. To isolate the sloughing-clay interval, a rig ran a 17.6-m long profile liner with packer elements on both ends. Crews ran the profile liner on 89-mm drill pipe and set it in the interval 1,237-1,254.6 m.

The upper 2.5 m of the profile liner expanded and tightly pressed into the production casing, which required a 142-mm diameter purpose-built expansion tool.

The lower end of the liner set in the gauged hole and was expanded with a 140-mm expander.

The profile liner successfully isolated the problem zone, with only a slight loss of the internal-hole diameter. The well continues producing oil with good rate and no problems have occurred.

The authors

Khamit Z. Kaveev is a deputy director general of the joint stock company OAO Tatneft, director of the External Economic Co. and has been in charge of external economic activity of Tatneft since 1999. Holds a PhD in economics from the Kazan Aircraft Institute. Previously worked in the Tatoilpetro joint venture where held the position of deputy director on economics and in the Tatex joint venture as a general director.

Rustam Kh. Ibatullin is an advisor to administration of Tatar Oil Research and Design Institute (TatNIPIneft) on foreign economic affairs. In 1955 he graduated from the Ufa State Petroleum Institute as a drilling engineer. Holds a PhD in technical science. His scientific and practical interests include trouble control while drilling, isolation of formations, increase of penetration rate. He participated in numerous drilling and completion projects in Russia and abroad.

Rafael G. Zagidullin is a senior research worker in the well construction and workover department in Tatar Oil Research and Design Institute (TatNIPIneft). He graduated from the Ufa Petroleum Institute as a mining engineer. His work interests are in oil well construction.

Albert G. Zainullin is a principal research worker in the well construction and workover department in Tatar Oil Research and Design Institute (TatNIPIneft). He graduated from the Ufa Petroleum Institute as a mechanical engineer. Holds a PhD degree in technical science. His work interests are in local well casing using expandable pipes.

Editor's note: Biographies for Nail G. Ibragimov, Gabdrashit S. Abdrakhmanov, and Nigmatyan K. Khamityanov can be found at the end of the article titled, "Expandable liners protect permeable zones in Russian oil wells."

Correction

In "Procedures correct temperatures for deep offshore wells" by I.M. Kutasov and M. Kagan (OGJ, Dec. 2, 2002, p. 56), the vertical water depth scales of Fig. 1 were incorrectly shown in reverse, with zero water depth indicated at the graphs' bottoms. The corrected graphs are shown at the left.