New generation rigs added to land rig fleet

Helmerich & Payne Inc. (H&P) has moved into the third phase of its FlexRig design with the deployment of the FlexRig3 rigs (Fig. 1).

As of Jan. 21, 2003, the company had 15 of the new units in the field at an average cost of $10.75 million each. An additional 10 FlexRig3s will be built (at the rate of two/month) and put into the field by July 2003.

FlexRigs, first introduced in January 1998 (OGJ, Nov. 16, 1998, p. 72 and Dec. 14, 1998, p. 53), are highly mobile land rigs specially engineered with health and safety of the workers, environmental protection, and drilling efficiencies in mind.

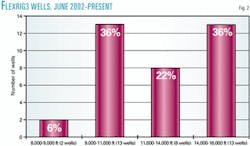

The rigs are designed to be cost effective at a wide range of depths (8,000-18,000 ft), with quick rig move and cycle times (Fig. 2).

"The rigs have basically the same engine horsepower, mud pumping hydraulics, and rotary capabilities of conventional 1,500 hp rigs built for 18,000-ft wells," says John Lindsay, vice-president of US land operations for H&P, "but in addition we have utilized innovative technology to improve in the drilling cycle."

The company says the rigs have several improvements over conventional 1,500-hp rigs:

- Rig moves in 2 days vs. 6 days.

- Reduction of flat line (not drilling) times.

- Application of near steady-state weight-on-bit for improved bit life and rate of penetration.

- Improved safety performance.

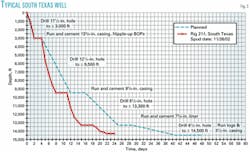

H&P says the decreased well cycle time from these rigs reduces costs for the operator and adds time value to the revenue stream from early oil and gas production. Fig. 3 charts a typical well drilled by one of the new rigs in South Texas.

Top drive integration

The new FlexRig3 has a Varco TDS-11HP 500-ton top drive integrated into the proprietary H&P-designed mast. It requires no incremental time for rig-up and rig-down, and it eliminates handling damage.

H&P says the top-drive unit eliminates two thirds of the connections required on a conventional rig, improves drilling times, and lessens the likelihood of sticking the drillstring in difficult formations.

Drawworks; driller controls

The drawworks is a Varco AHS-20SD powered by two GEB22 motors. The AC drives provide regenerative braking, says H&P, and more-precise control of the drillstring than conventional SCR-drive systems.

H&P uses the Varco V-ICIS and Electronic Driller (e-Driller) for integrated controls and information monitoring to the driller's station.

The system is installed in a controlled-climate driller's cabin (see cover). A single joystick controls the AC drawworks' speed while hoisting and lowering.

The Varco e-Driller system provides near-steady weight-on-bit while drilling and permits control of parameters including weight-on-bit, penetration rate, pressure differential across the bit, and drillstring torque.

These developments in controlling drilling parameters, says H&P, have improved bit life and penetration rates.

The block control system (BCS) minimizes surge and swab pressures as well as functioning as a crown-out and floor-protection system from the traveling equipment. H&P says the driller's job is improved by providing block positioning via the BCS logic and not the drillers constant monitoring of block position.

BOPHS

Historically, handling BOPs has been considered one of the most dangerous and labor-intensive activities on a rig.

The new rig's BOP handling system (BOPHS) allows the BOP stack to be transported in one unit on a transport skid (Fig. 4).

The process does not require the individual BOPs to be disassembled and assembled on each well.

Once in place on location, says H&P, the BOPs can be tested offline of the critical path. After casing is run and cemented, the BOPHS moves the tested BOP stack and centers it over the wellhead.

The BOPHS also picks up the stack to add wellhead accessories or spacer spools after casing is run, eliminating the need for rental BOP winches. A BOPHS can handle a three or four ram stack including an 11 in. or 13 5/8-in. annular preventer.

Tongs eliminated

H&P has addressed several productivity problems with the new rigs, says the company, and one important area was to reduce the use of manual tongs around the rotary table.

Each FlexRig3 has been outfitted with the Varco ST-80 Spin-Torque system (Fig. 5).

"This tool enables the floormen to make and break, spin-up, and spin-out drill pipe and drill collars without the use of manual tongs, spinning chains, or pipe spinners and catheads," says Lindsay.

H&P says with this new equipment its employees' jobs are more attractive by reducing the likelihood of injury and eliminating as much of the drudgery work as possible. The company says it has been successful in retaining its workers by continually exposing them to new methods, equipment, training, and technology.

Since 1998, says the company, turnover rate on its FlexRig units is half that of the rest of its fleet.

"Improved safety, environmental protection, and drilling efficiencies," says Lindsay, "add value to both operator and contractor."

The company says safety plays a big part in the FlexRig3 design. OSHA rates are 78% less than the IADC US land OSHA recordable rates for 2002.

H&P says the FlexRigs have been working at greater than 95% activity since 1998.