Offset-well data improve Zubair wellbore stability

Hussein Algburi

Iraq National Oil Co.

Baghdad

Mohamed Halafawi

Lazar Avram

Petroleum-Gas University

Ploiesti, Romania

An accurate determination of the stability of new Zubair field development wells is required to drill them safely. Analysis of previously drilled offset wells can help with this determination, addressing any problems with the stratigraphic column and reducing nonproductive time.

This article addresses problems encountered in the offset wellbores, their effects on well design, possible solutions, and preventative measures. It analyzes drilling data from the offset wells to detect, identify, and treat major problems. Then, in order to drill new wells and fulfill future development plans, special hole cleaning practices and pressure profiles are determined.

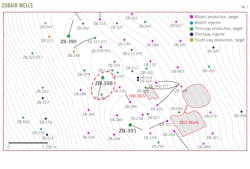

Zubair field

Zubair field is an onshore oil field with a processing plant, located in southern Iraq. Data for three drilled wells—A, B, and C—are available. To increase oil production from Zubair field’s third pay zone, South Oil Co.’s Zubair Field Operating Division plans three development wells: ZB-390, ZB-391, and ZB-398 (Fig. 1). Fourteen wells currently produce from the third pay zone.

Offset wells analysis

Table 1 shows statistics for Zubair field’s offset wells regarding well profile, time, and formation types and their corresponding mud type and operations. Zubair field has many drilled wells but the offset wells were selected in the zone where the new development wells will be drilled to fully analyze and evaluate all anticipated conditions. The most dangerous problems identified in the offset-well data were loss of circulation (LOC) and kicks, mainly in Dammam and Mishrif formations.

LOC identification, treatment

During drilling in the stratigraphic column of Zubair field (Fig. 2), and based on offset wells analysis, LOC will occur in formations such as Mishrif, Dammam, and Hartha. Bridging materials should therefore be added to drilling mud and plans for LOC treatment should be prepared to select the best strategy for dealing with loss.

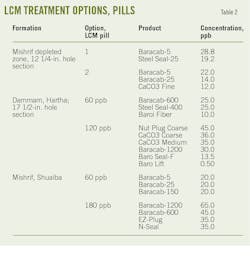

In the 12 1/4-in. hole section, bridging material concentrations should be maintained by adding pre-mix fresh volumes to the active circulation system, rather than pumping pills directly to the wellbore, to get maximum efficiency from the bridging materials and minimize the amount being discarded on the shaker. The total active circulating system will be loaded as shown in Option 2 of Table 2.

The concentrations mentioned in Table 2 in the active circulating system should be considered especially while drilling Mishrif depleted formation. Concentrations were selected based on lab work and study results for optimum isolating, bridging, or sealing of the Mishrif depleted zone in the presence of potassium chloride (KCl) polymer drilling fluids.

For lost circulation material (LCM) pill treatment of Dammam and Hartha formations, the maximum LCM concentration pumped through the bit is 120 ppb when using a rotary drilling bottom hole assembly (BHA) to drill the 17 1/2-in. hole section. If a directional BHA is used while drilling this section, bypass (PBL) and measurement-while-drilling (MWD) tools are included as part of it, and both 60 ppb and 120 ppb LCM pills must be available and ready to pump to deal with potential heavy losses in Dammam and Hartha if needed.

The 60 ppb LCM for Dammam will be required for a loss rate < 10 cu m/hr. The composition of this pill is shown in Table 2. The 120 ppb LCM pill for Dammam and Hartha formations will be required for a loss rate > 10 cu m/hr (composition also shown in Table 2).

Two LCM pill options exist for treatment for Mishrif and Shuaiba formations. The first is to use 60 ppb LCM pills for a loss rate < 10 cu /hr and the second to use 180 ppb LCM pills for a loss rate > 10 cu m/hr (Table 2).

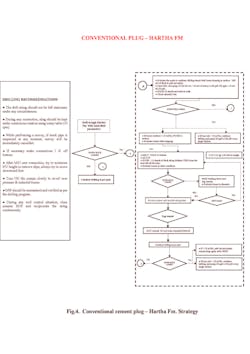

The decision trees for handling lost circulation zones in every permeable zone while drilling each well will depend on the severity of loss and the formation drilled. If losses in Dammam and Mishrif formation occur, Sentinelcem plug will be pumped. If the loss rate is < 10 cu m/hr, a first attempt to cure losses should be LCM pills administered through the PBL sub-BHA. Sentinelcem plug volume might vary depending on loss rate. If the loss rate is > 10 cu m/hr pull out should occur and an acid soluble cement plug with 1.5 specific gravity (sg) and oxyethylidenediphosphonic acid (OEDP) pumped for Mihrif formation, and a similar 1.44-sg plug for Dammam. A 116-bbl Sentinelcem-slurry spacer must be pumped for curing Mihrif losses and 58 bbl for Dammam. The drill string should be pulled out 10 m above the loss zone. Once partial losses occur, record the depth and drill 30 m more, spacing appropriately to make the connection near the loss zone.

Fig. 3 is the flow chart for treating Dammam formation losses with a Sentinelcem plug. The same chart would be used for Mishrif formation losses, but with different plug sg and number of barrels of Sentinelcem slurry-spacer pumped ahead. Fig. 4 shows the conventional plug flow and drilling recommendations needed to treat losses in Hartha formation. An acid-soluble cement plug should be pumped if Sentinelcem is not available in the field (Fig. 5).

Special hole cleaning

To reach Zubair field’s third pay target safely and reduce nonproductive time and costs resulting from hole cleaning problems, the following wellbore cleaning practices, deduced from the offset well data analysis, should be followed:

- A high-viscosity pill should be pumped every stand to ensure proper hole cleaning due to the deviated nature of the wellbore.

- At the end of a deviated section, a weighted high-viscosity pill enhanced with 0.1 ppb Barolift could be pumped to remove any cuttings and ensure the hole is adequately cleaned. Fracture limitations should be considered for weighted pill design.

- If a significant amount of cuttings are observed on shakers after the first Barolift sweep, consider pumping an additional Barolift pill (0.15-0.20 ppb), bearing in mind MWD limitations.

- Lubricant can be added if high torque is encountered. Begin with 0.5 vol % and if improvement is noticed the concentration can increase to a maximum of 1-2 vol %.

- When tripping in the hole, it is recommended to circulate at least one drill-string capacity at the casing shoe to ensure the BHA is free of debris before entering the open hole.

- Increase low-shear rheology (6 rpm) for 12 1/4-in. and 8 1/2-in. hole cleaning as required.

- Increase initial gel strengths to rapidly suspend cuttings when the pumps are turned off.

- If there are constraints on maximum pumping-out rate, use annular velocity as the indicator of hole cleaning. Fluid velocity is the key to cleaning an inclined annulus. Annular velocity recommended for 12 1/4-in. is 47-53 m/min and for 8 1/2-in., 96-108 m/min.

- When tripping in the hole, it is recommended to circulate 1.7 × bottoms up in 17 1/2-in. and 1.5 × bottoms up in both 12 1/4-in. and 8 1/2-in.

Pressure profiles

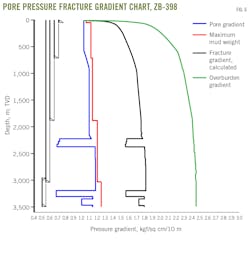

Pressure profiles include pore pressure gradient, fracture pressure gradient, overburden pressure gradient, and the corresponding mud gradient curves. The offset wells data allowed building pressure profiles for Zubair’s new development wells (Fig. 6). After setting 13 3/8-in. casing at 1,889 m, the new well is exposed to a low-pressure zone in Mishrif at 2,231 m. Two more low pressure layers are at 3,201 m and 3,358 m—upper sandstone (third pay) and lower sandstone, respectively—which appear after setting 9 5/8-in. casing at 3,039 m. Low pressure will be solved by controlling mud weight to prevent kicks and sticking. The remaining pressure profile will uniformly be distributed with depth.

The authors

Hussein El Gaburi is a lecturer in petroleum engineering at Alfarabi University College, Iraq, and a petroleum engineer in Iraq National Oil Co. He is also a PhD student in the department of drilling, Petroleum-Gas University of Ploiesti. Hussein holds a BS in mechanical engineering from Baghdad University and an MS in petroleum engineering from UPG Romania.

Mohamed Halafawi ([email protected]) is a PhD student in the department of drilling, extraction, and transportation of hydrocarbons, Petroleum-Gas University of Ploiesti (UPG), Romania. Halafawi was also a lecturer and teacher assistant in petroleum engineering at Cairo University from 2011 to 2017, from which he earned BS and MS degrees in petroleum engineering. He has published more than 12 technical articles in international journals and conferences and one textbook. He is a member of SPE and AGIR scientific societies.

Lazar Avram is a professor and the head of the department of drilling, extraction, and transportation of hydrocarbons, Petroleum-Gas University of Ploiesti, where he teaches undergraduate and postgraduate classes and supervises an extensive research in onshore and offshore drilling. Avram is also a visiting professor at various universities in France, Greece, UK, Lebanon, and Tunisia. He holds BS and MS degrees from UPG in Romania, and a PhD from IFP School, France. He worked as an engineer and recently as a consultant for Romanian companies.