Umiat: a North Slope giant primed for oil development

Alaska's giant Umiat oil field, discovered in the late 1940s by the US Navy in search of new sources of oil after World War II, remains undeveloped to this day.

The field is untapped in spite of delineation by 12 legacy wells; the shallow depth of its consolidated, productive reservoirs; sweet, light 37° gravity oil; and over 1 billion bbl of original oil in place.

To this point, remoteness (92 miles from the Trans Alaska Pipeline System (TAPS)), permafrost, and low reservoir energy have been the main development challenges. All of these challenges have been addressed through modern technological advancements such as multilateral horizontal drilling, electric submersible pumps, and cold gas injection for pressure maintenance that bring Umiat development closer to fruition.

Remoteness and environment is still a key challenge; however, the State of Alaska announced in December 2009 an aggressive plan to build an all-season gravel road from TAPS to the Umiat area that would substantially reduce the threshold for commerciality.

Geologic mapping by the US Navy in 1944 first defined the Umiat anticline with its associated oil seeps.

The Navy and the US Geological Survey conducted an extensive mapping and drilling program in this remote part of northern Alaska from 1944 to 1953. In particular, between 1946 and 1952, a total of 11 wells were drilled on the Umiat anticline. Eight wells have an oil column and two wells had long-term tests.

Much of this early drilling was experimental utilizing a variety of types of drilling rigs as well as different types of drilling fluids. A deeper test, the Seabee-1, was drilled in 1978 and tested gas from a deeper horizon.

The Navy established an air base at Umiat and used the light oil for fuel. So unlike other Arctic pending developments, Umiat has an established footprint including an airstrip, lodging, warehouse storage, etc.

Renaissance Alaska LLC, through Renaissance Umiat LLC, controls 19,358 acres over the undeveloped Umiat oil field and a portion of the undeveloped Gubik gas field 12 miles east-northeast. Arctic Falcon Exploration LLC is a minority owner of Renaissance Umiat LLC.

Since acquiring the acreage in 2006 and 2007, Renaissance has derisked the project through extensive geoscience studies and an 86 sq mile 3D seismic survey shot in 2008. Renaissance is currently formulating the plan of development.

Umiat location

Umiat is in the central part of the North Slope at the northern edge of the Brooks Mountain Range thrust-fold belt (Fig. 1).

It is in the eastern part of the National Petroleum Reserve of Alaska (NPR-A) about 220 miles south of Prudhoe Bay oil field.

Umiat is in the leading edge of the fold belt surrounded by the Gubik, East Umiat, and Wolf Creek structures (Fig. 2) which have seen renewed appraisal drilling by Anadarko Petroleum Corp., Petro-Canada (now Suncor), and BG Group (British Gas) during 2008 and 2009 to assess gas reserve potential in preparation for nominating space in a proposed Alaska gas pipeline system.

Geoscience discussion

The Umiat structural trap

The map in Fig. 3 is a surface geological map of the Umiat anticlinal structure constructed by the USGS.

The southern part of the structure is masked by alluvium (yellow) from the Colville River, and a tributary of the river cuts into the structure and exposes the uppermost oil-bearing reservoirs.

Fig. 4 is a 3D seismic subsurface structure map at the top of the Upper Grandstand, one of the main productive horizons at Umiat. This map shows the outline of the 86 sq mile 3D seismic survey.

The Upper Grandstand two-way time values interpreted from the 3D seismic survey were converted to depth using the time/depth relationships derived from a check-shot survey from the Seabee-1 well shown by the arrow. The area inside the lowest known oil (LKO) in the Upper Grandstand reservoir is 7,500 acres.

Reservoir section

The productive reservoirs at Umiat are in a Lower Cretaceous-aged sandstone interval known as the Nanushuk Group (Fig. 5).

The Nanushuk Group is made up of the Ninuluk, Chandler Tongue, Upper Grandstand, and Lower Grandstand formations. The Upper Grandstand mapped structural horizon in Fig. 4 is highlighted. The Nanushuk Group consists of shallow marine shoreface and deltaic sandstones and contains over 600 ft of net sandstone available for net pay at Umiat.

Reservoir architecture

The block diagram in Fig. 6 shows the 12 legacy wells drilled at Umiat, the Upper and Lower Grandstand main productive horizons, and a possible deeper objective below the shallow oil field.

Umiat is a large ultrashallow (500 to 1,400 ft) oil accumulation. The solid green color represents proved, probable, and possible recoverable reserves of 250 million bbl of oil, and the stippled green pattern represents potential additional resource. Compared with the 7,500-acre Upper Grandstand oil accumulation, the Lower Grandstand oil accumulation has an areal extent of 5,600 acres.

Well correlations and rates

Fig. 7 is a correlation cross section encompassing all the legacy wells drilled at Umiat.

The first well on the left is the Seabee well followed from left to right by wells 1 through 11. Note the erosion of the upper oil bearing reservoirs in wells 2 through 5. The lower oil bearing sandstones in the Chandler Tongue are not eroded, and the basal Chandler Tongue shale provides the top seal for the Upper Grandstand reservoir.

Across the top of the cross section are the oil pump rates for the wells. The Seabee well, on the far left, was drilled to evaluate deeper objectives and not tested in the shallow productive horizons.

Wells 1 through 3 were drilled with fresh water, and ice formed across the perforations in the zone of permafrost resulting in no flow. The low pump rates in the remainder of the wells were caused by inadequate pump capacities and formation damage from very high mud weights.

The two long term tests were at Well 5, which pumped at the rate of 400 b/d of oil for 93 days, and Well 9, which pumped 200-300 b/d of oil for 45 days. It was noted for Well 5 that the rate was limited to the capacity of the pump; the capacity of the well is not known.

Reservoir-fluid properties

The Navy acquired conventional core in the productive horizons in almost every legacy well, particularly in the main Upper and Lower Grandstand reservoirs.

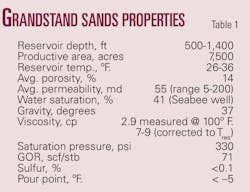

Fig. 8 is a cross-plot of Upper and Lower Grandstand porosities vs. permeabilities for most of the wells with an inset picture of the reservoir rock from core.

The Grandstand reservoirs are fine-grained, consolidated sandstones with an average porosity of 14% and an average permeability of 55 md.

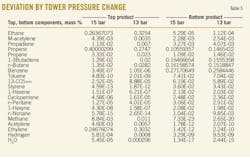

Porosity and permeability for the Grandstand reservoirs are based on 200-plus core samples taken from 10 wells. The porosity of the productive reservoirs varies from 10% to 20% with an average of 14%, and the permeability varies from 1 md to 200 md with an average of 55 md (Table 1).

Relative uplift studies of the North Slope have shown that these reservoirs were originally buried to a depth of 6,000 to 7,000 ft, and apatite-fission dating techniques indicate they were uplifted to their present shallow elevation in Lower Tertiary time during the formation of the Brooks Range thrust-fold belt.

The fluid properties are also shown in Table 1. The Umiat crude is light sweet oil with 37° gravity. The viscosity measured on five oil samples is nearly 3 cp at 100° F. After applying correction for reservoir temperature it is estimated to be 7-9 cp.

The pour point of Umiat oil is less than –5° F., which indicates that the oil is mobile in the reservoir that is within permafrost, primarily the Upper Grandstand sands. This has been proven by the oil produced in several tests from the reservoirs in the permafrost.

Engineering discussion

World class structure

As of 1960, Umiat was expected to be the largest oil field in Alaska.

The discovery of the supergiant fields on the northern coast in the late 1960s decreased the interest in developing what is still a large accumulation compared to the average size of an oil pool worldwide.

As economic parameters changed over the last 50 years, remote and complex reservoirs have become viable. Umiat continues to draw attention as one of the few remaining light oil reservoirs in Alaska, and in the US, that has not been developed.

Field remoteness

The first challenge is the remoteness of the location.

The nearest commercial traffic access road is the TAPS pipeline haul road (Dalton Highway) almost 92 miles to the east. Although the Prudhoe Bay area has significant oil and gas infrastructure, it is located 220 miles away even after an Umiat access road is built. However, there is an airstrip for year round access, and Umiat has lodging, warehouse storage, etc.

Umiat is planned to be developed using the proven methods that were employed for the Alpine development, which was roughly 70 miles west of Prudhoe Bay. At Alpine large sealifts and truckable modules were used to transport the facilities, including ones constructed in Alaska, Canada, and the Lower 48.

Pay opposite permafrost

The Arctic environment presents the next most significant challenge. The year-round average surface temperature near 0° F. makes permanent habitation difficult and expensive.

One challenge particular to Umiat is the presence of at least part of the oil horizons within the permafrost zone. Although this should not immediately impact primary production rates when compared to other reservoirs with similar oil saturation and oil viscosity (at reservoir conditions), it represents unique challenges concerning secondary recovery or pressure maintenance operations.

A discussion of adverse sand-face plugging behavior in a 1960 US Bureau of Mines report1 leads one to assume that keeping the formation cold and stable (steady state conditions) will result in higher oil permeability than allowing water to thaw then refreeze at thermal boundaries.

Any water injected into the reservoir would tend to freeze and block future injectivity. Any gas injected above reservoir temperature would tend to thaw, and then refreeze any interstitial water it came in contact with. Although the behavior has not been documented in the Umiat related literature, it is likely that sweep efficiency would be adversely affected by a moving water front preceding a hot injection gas front.

With this in mind, cold gas injection is proposed by Renaissance as the preferred pressure maintenance technique and was evaluated by both the Bureau of Mines and recent third party reservoir engineering studies.

Although the Bureau of Mines report stated that solution gas drive at low reservoir pressure results in reasonable recovery factors of 29% to 45% due to the significant expansion of a small amount of gas, makeup injection gas would be necessary to optimize recovery from the low pressure reservoirs. A recent third party reservoir engineering study estimates typical recovery factors of 22% for the UGS zones and 45% from the LGS reservoirs.

These recoveries are currently being researched further at the University of Alaska, Fairbanks. For the reserves study, parameters were risked downward to account for reservoir heterogeneity and typical underperformance of horizontal wells compared to predevelopment simulation studies.

Renaissance has gas resources in the area for pressure maintenance.

Horizontal drilling

Since 1960, horizontal drilling has provided viable rates in fields that were previously uneconomic.

On average, horizontal wells produce two to three times the rate of the similar vertical well.2 Recent theoretical calculations predict rates could increase by 6:1.3

In reservoirs like the Bakken in Montana, the increase in productivity due to both horizontal drilling and multiple hydraulic fractures has provided the only means of economic production.

Horizontal drilling in Umiat field would provide several benefits.

The first benefit would be reduced well counts to access the entire structure and minimize additional footprint.

The second benefit would be to allow segregated access to large portions of the top and bottom of each of the target sand bodies.

The third benefit is simply that rates per wellbore of 1,000 b/d of oil or more can be expected from dual lateral wells.

Artificial lift options

Given the complex wellbore geometry, artificial lift optimization will become an important driver for Umiat profitability.

If recovery from the development is to be maximized, withdrawals of all liquids at the lowest possible bottomhole pressure will be a goal of the artificial lift system. The use of electric submersible pumps (ESPs) is currently the preferred option. However, with gas injection for pressure maintenance, high gas-oil ratios may prevail with time.

Recent experience in high gas/low liquid horizontal producing environments has shown that fluids accumulating in low spots or "sumps" along the horizontal wellbore length create an oscillating gas surge that unloads fluids but also tends to vapor lock the ESP intake.

The ESP is planned to be placed in the deepest straight and horizontal section of the lower lateral of each well. This should cause all liquids to be removed from the wellbore at the lowest possible removal point, thus using gravity and fall-back to aid in gas separation.

Since the wells are shallow, the pump horsepower requirements are not extreme and a short pump can be pushed into the horizontal section if the wellbore size is large enough and doglegs are kept reasonable.

Gas lift is the other accepted technique for producing below a curved portion of a wellbore. With gas injection as the secondary recovery method, gas lift is a viable option and gas breakthrough will provide some additional lift capacity.

Lift gas delivered at 400-600 psia would be sufficient to lift significant volumes of Umiat oil. This option may be less capital intensive than ESPs but requires greater gas compression volumes.

Development plan

Renaissance shot an 86 sq mile proprietary 3D seismic survey in the winter of 2008 to confirm the mapping of the 7,500-acre shallow structure and to assess the deeper potential.

The company has also focused on the plan of development and contracted third parties on pipeline route and cost, facility layout and costs, horizontal (lateral) development techniques, and obtained an independent reserve report. In addition, the University of Alaska at Fairbanks has a Department of Energy grant to, among other things, confirm cold gas injection as the preferred pressure maintenance mechanism.

The development plan includes a 115-well program split between Upper and Lower Grandstand using multilaterals on 80-acre spacing for 78 producers and 160-acre spacing for 37 gas injectors.

The pipeline from Umiat is expected to tie-in to TAPS at Pump Station 2. Peak field production should reach 50,000 b/d of oil. Total development cost is estimated to be $1.7 billion. Currently, further technical studies are underway to finalize the plan of development prior to obtaining funding for project sanction.

Investment environment

Alaska is a stable domestic environment with significant fiscal incentives for investment, including fungible tax credits between 45% and 65% for drilling and development costs for small producers.

Majors have built the footprint, and there is ample infrastructure capacity. The late 2009 price environment rekindled activity on the North Slope of Alaska. Superindependents such as Pioneer Natural Resources at the Oooguruk project are applying proved technologies and leading this thrust.

Alaska receives almost 90% of its revenue from oil and gas production. Although the state has increased the overall severance taxes on production, the overall impact of the discounted value is minimal due to the up front tax credits. The tax credits lower the "at risk" investment; in other words, the state shares the risk dollars.

Progressing the development

In closing, Umiat has world-class potential and is a low geological risk development project. Technological advances in drilling in permafrost, horizontal drilling, artificial lift, and a real price increase in oil have brought Umiat to the development stage.

Acknowledgments

We acknowledge the contributions of the entire Renaissance team: Vijay Bangia, David Doherty, Craig Moore, David Fulton, and Paula Hastreiter.

Credit should go ARC Financial Corp., whose investment has allowed Umiat to be derisked and progressed towards development, and to Arctic Falcon Exploration LLC who originally captured the key leasehold at Umiat and is one of the strongest advocates. Also, recognition is given to Ryder Scott & Associates for its contribution to the engineering discussion and the technical work in particular on artificial lift and analogs for horizontal wells.

References

1. Baptist, Oren C., "Oil Production from Frozen Reservoir Rocks, Umiat, Alaska," US Department of the Interior, Bureau of Mines, 1960, 22 pp.

2. Beliveau, Dennis, "Heterogeneity, Geostatistics, Horizontal Wells, and Blackjack Poker," SPE 30745, Society of Petroleum Engineers, Richardson, Tex., 1995.

3. Joshi Technologies International Inc., Umiat Field, Alaska, "Development with Horizontal Wells," report for Renaissance Umiat LLC, Houston, 2008, p. 4.

Bibliography

Gryc, George (ed.), "Geology and Exploration of the National Petroleum Reserve in Alaska, 1974 to 1982," USGS Prof. Paper 1399, 1988, Plate 2.1.

Molenaar, C.M., "Umiat Field, An Oil Accumulation in a Thrust-Faulted Anticline, North Slope of Alaska," Rocky Mountain Assoc. of Geologists, 1982, pp. 537-548.

Collins, F.R., et al., 1966, "Geologic Map and Sections of the Umiat-Maybe Creek Region, Alaska," USGS Prof. Paper 303-H, 1966, Plate 52 (east half).

Collins, F.R., et al., "Test Wells, Umiat Area, Alaska," in "Exploration of Naval Petroleum Reserve No. 4 and Adjacent Areas, Northern Alaska, 1944-53, Part 5, Subsurface Geology and Engineering Data," USGS Prof. Paper 305-B, 1958, pp. 71-204.

State of Alaska, Department of Transportation and Public Facilities, Northern Region, Foothills West Transportation Access, Draft Interim Corridor Analysis/Decisional Matrix, Project No. 62210, 2009, pp. 1-125 (http://dot.alaska.gov/nreg/foothills/index.shtml).

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com