Methodology of first US PDH plant offers lessons for future projects

Randy Miller

Consultant

Houston

A confluence of ongoing uncertainty regarding the post-pandemic economy’s recovery and increased corporate focus on investments aimed at achieving low-carbon operations in line with the global energy transition is slowing US operators’ development of standalone petrochemical projects.

While spending understandably has fallen for greenfield chemical developments amid rising equipment costs and regulatory permitting hurdles, financial decisionmakers may be peremptorily neglecting potentially lucrative opportunities offered by brownfield projects.

Compared with their greenfield counterparts, brownfield chemical projects enable an expedited time-to-market and reduced environmental footprint by leveraging the reuse of idled industrial sites, infrastructure, utilities, permits, logistics, and certain operating units already in place. With the growing selection of technologies designed to help achieve long-term net-zero goals now available for unit retrofits, these brownfield projects can also now provide a pathway to achieving even further site-wide emissions reductions than grassroots undertakings.

To illustrate the benefits of a hugely successful brownfield chemical development, this article—for the first time ever—presents a comprehensive account of PetroLogisitics LP (PL) subsidiary PL Propylene LLC’s 2010 delivery of North America’s first—and at the time, the world’s largest—propane dehydrogenation (PDH) plant for production of on-purpose propylene, at the Houston Ship Channel (Fig. 1).

In addition to providing key details of the strategies PL’s engineering and operations teams employed to bring the plant online—from early phases of development, technology selection, engineering, procurement, construction, and commissioning, through to its subsequent exceeding of designed nameplate capacity—the article discusses lessons learned during the process still highly relevant for chemical operators today when considering current and future projects.

Setting the scene

In 2003-04, when fracking was in its infancy and its future uncertain, US propylene supply came from refineries and ethylene plants designed to crack a heavy feed slate. At the time, major chemical companies and financial institutions predicted that future investments in PDH plant development for on-purpose propylene production would only occur in Saudi Arabia and the Asia Pacific.

At the time, PL was unaware of the many hurdles it would face, including:

- The 2007-08 financial crisis.

- Supply-chain issues that would drive major equipment deliveries beyond 24 months.

- Difficulty finding bidders for some major equipment.

- Labor and supply costs that would threaten the project’s schedule.

In addition, no Houston-based EPC firm was willing to provide front-end engineering and design (FEED), and the equity-debt financed revamp project ultimately would be built on a time and material basis.

Despite these problems, PL’s internal project teams proceeded with the multiyear endeavor based on their collective philosophy of applying a direct, hands-on approach to every dimension of the project from early development to final completion.

This internal approach paved the way to establishing constant, collaborative relationships with external project partners—including consultants, technology and equipment providers, engineers, and contractors—that ensured the $600-million plant’s commissioning in 2010 and ongoing profitability for PL that led to its acquisition by Koch Industries Inc. subsidiary Flint Hills Resources LLC in 2014 for $2.1 billion (OGJ Online, May 28, 2014).

Preliminary considerations

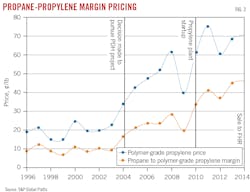

A grassroots project would have been too expensive given a low 13¢/lb propane-to-propylene margin (Fig. 2). PL also sought to leverage existing assets into a larger, more profitable company as it had done with subsidiary PL Midstream LLC in Louisiana.

Based on these internal determinations, PL’s owners engaged the author as its consultant to assist in determining the feasibility of converting existing sites to PDH service. Numerous options involving existing installations were evaluated, including the relocation of unused PDH assets in Mexico, all of which were deemed too expensive.

After thoroughly vetting existing infrastructure options, the team selected ExxonMobil’s former Houston olefins plant (HOP) on the Houston Ship Channel. Originally commissioned in 1965, it was mothballed in 2004 after failing to sell.

Designed to process off-gas from a neighboring refinery and crack recovered propane and ethane, the HOP’s oversized recovery section captured the team’s attention, as its charge-gas compressor potentially could match up to discharge from a well-chosen new booster compressor. If that worked, there would be a good chance that the existing propylene and ethylene refrigeration compressors could work as well. Work with compressor suppliers confirmed that all of HOP’s existing compressor nozzles and casings were large enough for the proposed PDH plant’s design needs.

Technology selection

The next step was to select the best available PDH technology for retrofitting HOP equipment, which in 2004 included two choices: the older, fixed-bed Catofin process from Lummus Technology LLC, or Oleflex technology introduced in 1990 by Honeywell UOP LLC.

While UOP’s Oleflex appeared to be the new-and-improved frontrunner, the first step in determining how well existing equipment matched up with each technology required establishing the proposed PDH plant’s sitewide processing-flow scheme. Since most equipment for the project would be reused, PL could not use the classical grassroots approach of a licensor supplying the site’s process design package. Instead, PL decided the licensors would provide their proprietary reactor inlet-outlet license package and that its consultant would design the remainder of the site using open-art expertise gained from previous plant design.

The optimal processing scheme called for a high-pressure, dual de-ethanizer design that included an expander-recompressor and pressure-swing adsorber to provide both a minimal energy footprint and a hydrogen product that could be sold to market. Process simulation modeling determined that the Catofin technology would accommodate the greatest reuse of existing equipment and provide the lowest costs. The model also indicated all existing HOP compressors, utility and storage systems, and distillation towers could be repurposed. Although the existing propylene splitter towers were too small for immediate use, they could be used for future expansion.

Technology comparisons also showed the Catofin catalyst offered an advantage in cost, yield, and lifetime, a critical component in the assessment since ultimate propylene yield declines with catalyst activity. Based on inspection of spent Catofin catalyst after its normal 2-year life, it was determined that catalyst life could be extended to 3 years, longer than the expected life of UOP Oleflex catalyst (based on due-diligence data).

Propylene yields were initially difficult to compare because they were not provided at equal propane conversion values. Yields are obviously higher at lower conversion values but at the cost of higher propane-recycle costs. Once the propylene yield values were obtained for equal propane conversion values, however, it became clear Catofin catalyst yields were better than those of Oleflex.

Since achieving plant capacities above nameplate-design levels through built-in reliability and operability enables enhanced profit for the owner beyond base-project returns, the final step in technology selection considered potential value creation based on a combination of the following:

- Ultimate net capacity, or capacity as measured by onstream time.

- Capacity above design rate.

- Propylene yield, decay.

- Catalyst life.

- Turnaround frequency.

Discussions with each technology reference gave PL confidence that Lummus’ Catofin technology would deliver the highest level of net capacity, and hence profitability.

PL chose Catofin technology originally based on a 400,000-tonne/year (tpy) site capacity, which later changed to 500,000 tpy after the simulation model confirmed extra-recovery section capacity. In the end, the model predicted ultimate capacity 20% above the 500,000-tpy design capacity.

Engineering

During preliminary FEED, PL discovered an error in projected utility consumption that would lead to an additional $44 million/year in operating costs. A way to achieve both the required process temperature and pressure in a single step, completely eliminating the $44-million annual cost increase, was developed. In addition to bringing the project back on track, the consultant’s development of the single-step process led to a patent.

PL completed FEED with a very small team, and was successful for the most part because of the previously completed site process simulation model. Another project-threatening issue, however, surfaced early in FEED.

PL’s internal team requested the external EPC team to provide a midterm cost estimate to confirm the project’s $600-million placeholder in the PL business model. After the resulting estimate indicated a project cost of $900 million, PL brought in an expert recently retired as head of cost estimating for a major chemical company to verify the discrepancy. After the expert sided with the EPC team’s escalated cost estimate but before notifying PL management of the 50% increase in capital cost that likely would lead to the project’s cancellation, the consultant requested a review of all estimate details and assumptions. The EPC team’s assigned Lang factor (total installed cost/major equipment cost) of almost 6.5 for a revamp project simply seemed too high.

After reviewing material takeoff assumptions used by the estimating team, it became clear that one of the key issues was a double-counting of pipe lengths, wiring, steel, and cable, among other materials. EPC estimators had used a set of fixed, bulk-quantity assumptions for the inlet and outlet of every piece of equipment. The double-counting occurred because, for example, the estimators included the length of inlet pipe to a piece of equipment as well as the same length of pipe for the outlet of the upstream equipment.

After resolving these discrepancies, the resulting cost estimate came in right at $600 million, ultimately reflecting the project’s final cost to complete. This was a lesson both in perseverance and in paying close attention to all assumptions and details for one of the most critical exercises in FEED, as the midterm cost estimate can easily sink a project if handled improperly. The effort also helped demonstrate that PL was coming in at 65% of new-build cost by revamping the existing HOP site.

Construction hurdles

Using its hands-on approach of internally managing and monitoring the project, PL’s team was able to establish and ultimately achieve an aggressive 18-month construction schedule.

Fig. 4 shows the final orientation of reactors in the plant structure to stress how critical on-time delivery was to maintaining overall project schedule.

Preplanning payoffs

During construction, preplanning measures undertaken by PL’s internal teams were vital to completing the project on time and on budget. A prime example included the construction team’s preplanning for the project’s 340-ft tall, 26-ft diameter propylene splitter tower, for which optimum design required shipping the tower in three pieces to allow for traying at grade and lifting-welding of the two top pieces.

PL also believed that everyone should be an owner of the plant and gave every employee stock shares, ensuring all were aligned with PL’s goals.

PL’s PDH plant was completed with one of the lowest safety incidents on record, and during operation from its official startup in October 2010 until the plant was sold to FHR in 2014, there were no recordable injuries.

Success beyond startup

Like any project, the PDH plant experienced startup issues, including a few technology-based issues requiring resolution in the months following commissioning. PL’s teams were able to correct a purity issue in the splitter tower and an unidentified issue in one of the revamped HOP compressors during a single shutdown.

During startup, the propylene splitter tower was unable to make on-spec polymer-grade propylene (PGP). Since the tower was also designed to produce chemical-grade propylene (CGP) from a lower draw point, PL was able to temporarily meet customer product volumes by substituting CGP for PGP.

To address the situation, PL brought in a noted distillation expert to help identify the specific tray performance issues and, together, develop a plan to correct the problem. To do this, however, required waiting for an opportune time to shut the plant down, as the most aggressive schedule at the time still required a 14-day outage.

That opportunity came June 9, 2011, when the plant shut down because of an issue with the revamped heat-pump compressor’s rotor. PL tasked the tray vendor to simultaneously deliver materials from multiple suppliers to ensure the 14-day schedule could be met.

By April 2011, the PDH plant was achieving capacities above 120% of its nameplate design. Even while operating at these over-design capacities, the plant was also able to achieve the originally predicted 3-year catalyst life, making PL the first Catofin PDH licensee to do so.

Back to the future

In 2023, US petrochemical companies find themselves in the new world of weighing potential capital projects based on factors that include both access to abundant feedstock resources and the need to balance these with climate goals. Projects must now be both profitable and environmentally friendly.

As PL’s PDH project history illustrates, project profitability requires operator control of each step in the process, including dedicating direct staff to evaluating and constantly monitoring issues related to safety, capacity targets, reliability, costs, schedules, and technology performance.

More than ever, the outcome of a project—whether brownfield or greenfield—can be determined early in the process by establishing a true partnership of innovative engineering, operations, construction, cost estimating, and EPC relationships.

Collaboration during preliminary FEED and FEED with key original equipment manufacturers can also minimize future discovery and project-growth risk by helping lock in project scope much earlier. This derisking strategy enables early informed decision making that expedites senior management approvals.

The author

Randy Miller ([email protected]) was vice-president of engineering for PetroLogistics LP during development, construction, startup, and operation of the Houston PDH plant until its sale in 2014. In 2017, he joined PetroLogistics II LLC as senior vice-president of engineering and operations, where he served until 2022. Now an independent consultant for major chemical projects, Miller most recently completed detailed preliminary front-end engineering and design development efforts for a major US-based biopolymers project. He holds a BS (1988) in chemical engineering from Texas A&M University, an MBA (1992) from the University of Houston—Clear Lake, and is a registered professional engineer in Texas.