US shale gas-advantaged projects strain toward finish line

The shale gas revolution in the US-born nearly a decade ago of technological advancements such as horizontal drilling and hydraulic fracturing that have proven shale plays such as the Marcellus, Utica, and Haynesville prolific-has provided an abundant locally sourced feedstock to a variety of industries that fuel both the US and world economies.

Locally, it has spurred a massive buildout of petrochemical facilities to produce ethylene, propylene, methanol, and ammonia, the building blocks for products such as plastics and fertilizers. According to a tally of US shale-related chemical industry projects by economists at the American Chemistry Council (ACC), some 266 projects representing $164 billion in cumulative investment have been announced, with 40% completed or under construction, 55% in the planning phase, and 61% led by firms based outside the US.

The latter stat, along with rising global demand, reinforces the assertion that the US chemical revolution is indeed a global one. A report commissioned by ACC and published last year forecasts gross US exports of chemical products, including plastics, will double to $123 billion by 2030 from $60 billion in 2014.

Merely liquefied, US shale gas is expected to transform the global gas market, one complicated by exporters widely seen as dubious-at-best such as Russia, and a diverse set of cautious importers in Europe. US LNG suppliers will add a new dimension of flexibility to the market, with the country becoming the third-largest exporter behind Qatar and Australia by 2021, the International Energy Agency forecasts.

LNG export facilities are proliferating alongside the shale gas-fed chemical facilities on the US Gulf Coast, with Cheniere Energy Inc.'s Sabine Pass, La., facility shipping the Lower 48's first LNG cargo of the century last February. Many more cargoes are set to follow in the near term with other facilities currently under construction.

Busy owners, contractors

It's been a hectic time for project owners and their contracted engineering, procurement, and construction firms, the entities tasked with undertaking this massive buildout. While they're happy to have the work, dramatically changing markets from the time these US chemical and LNG projects were sanctioned have resulted in shifting expectations and even stricter budgets and schedules. During Rice University's 19th Global Engineering and Construction Forum held in September in Houston, consultants, analysts, leaders of several international EPC firms, and one owner came together to discuss the challenges they face as they push these projects toward what they hope is successful completion.

Ron Corn, senior vice-president of projects and supply chain for Chevron Phillips Chemical LP (CPChem), offered perspective as the group's lone owner representative. Nearing the finish line is his firm's $6-billion Gulf Coast petrochemicals project at Cedar Bayou and Old Ocean, Tex., which includes a 1.5 million-tonne/year ethane cracker and two world-scale polyethylene units that will each produce 500,000 tpy of resin. It's the first greenfield cracker project in the US in more than a decade and will be one of the largest ethane crackers in the country once completed.

Research and consulting firm Wood Mackenzie Ltd. says near-term global ethylene demand is robust, projecting growth of 3%/year, slightly higher than global gross domestic product growth rates. Supply is dominated by crude-based feedstocks naphtha and LPG, but ethane remains a major source. Due to the shrinking costs of gas and coal relative to higher prices associated with oil, North America and China are now adding most of the world's new ethylene capacity.

The CPChem Gulf Coast complex will help fulfill the rising global demand for high-quality plastics in industries including rigid and flexible packaging, industrial films, automotive, pressure pipe and conduit, and various consumer goods. Slated to be among the first to start operations in the new batch of North American ethylene projects, the Gulf Coast project's concept was first explored in 2010 at a time when most of CPChem's investment was going toward the Middle East.

The shift in strategy attracted extra scrutiny from major stakeholders within CPChem, and required the project team to continue to rethink the way it executes megaprojects while tackling the challenge of cost control. Reflecting on the project thus far, Corn said his firm's board made it clear that "if we want to do another project like we're doing today, then we better have a better answer to the question on how to take some cost out."

Corn cited research from advisory firm Independent Project Analysis Inc. (IPA) that determines a project is a "failure" if its costs grew more than 25%, cost competitiveness was at least 25% worse compared with the rest of the industry, execution schedule slipped by at least 25%, execution schedule competitiveness was at least 50% worse than the industry, and if severe and continuing production problems occurred in the first 2 years. Under this criteria, some 40% of projects at less than $500 million and 65% of megaprojects fail. Corn said IPA's analysis is far more lenient than his company's board.

Among those providing a contractor's perspective at the forum, Keith Ackley, vice-president of project management in KBR Inc.'s engineering and construction business, noted that many of these projects are several-year-long endeavors. "Compare [the end of a project] to where we were 8 years ago when we made some pretty important fundamental decisions about the flexibility of this plant, and today it comes online and somehow doesn't meet the expectations of today's market. I can tell you the guy who made that decision for that owner 8 years ago probably doesn't work for that owner anymore."

In a separate presentation at the forum, Curt Watson, chief executive officer of Infinity Group, a Wood Group company, said he's observed that project owners' commercial leaders are becoming primary project decision-makers over the owner's project leaders, meaning contractors are seeing less forgiveness and understanding for cost and schedule challenges. Contractors therefore have to identify who is that primary decision-maker and create a dialogue with them, he suggested.

Assessing new approaches

One new approach used by CPChem during the Gulf Coast project has included the creation of senior management-sponsored teams with both EPCs and major equipment suppliers. "I think this is extremely critical in meeting one of our core goals, which was that engineering, and most importantly, procurement, was done on time." This approach appeared to be validated, he said, when he drove by the site 18 months ago and essentially saw an unassembled cracker lying on the ground ready to be put together.

Stressing that project teams should "start with the end in mind," Denis Menegaz, Fluor Corp. vice-president of project management and process technology, said one solution for reducing project costs is to "look at the specifications and standards that we're starting with." Fluor, in a joint venture with JGC Corp., is performing EPC work on the Cedar Bayou ethane cracker and its associated offsite components. Fluor's scope of work includes engineering and construction for the outside battery limit scope and direct-hire construction for the entire cracker project.

Menegaz noted that in many cases, owners have good specs that have been designed and proven over many years, but once those specs are applied to a certain project, they prove too expensive. His firm has been looking at a "zero-based engineering approach" using specs and standards developed by the industrial community. "For the most part, we have some of the price coming down on some of these projects," Menegaz said.

Regarding modularization, Menegaz said that it has to be customized to the site because his firm is finding "one size does not fit all." Variables such as access to the site and logistics, and limitations of labor availability have to be determined in the early phases of front-end engineering and design, he said. "If you change your modularization approach once you start detailed engineering, you're going to have a project that's going to have some additional costs," he said.

Justin Dahl, principal at Westney Consulting Group, told OGJ in a separate discussion on Gulf Coast ethylene projects that he believes "modularization is not a panacea as far as helping to improve productivity." Founded in 1978, Westney Consulting Group advises the oil and gas, power, chemical, and mining industries on major capital projects. "We've had some projects that have used it for the right components and found it beneficial, and others, just by what was chosen to be modularized, actually made the construction and layout of the projects more difficult for the other units that were not modularized," he said. "It's a mixed bag... People are still trying to figure out what's the best way to use it."

Dahl added, "We have heard there's been a lot of design evolvement." As more and more polyethylene trains are built, for example, concrete and steel quantities have grown beyond what was originally intended for the scale of the project. Why is that the case? "That's something now that's being looked hard at by a number of different owners."

Construction inefficiency

Westney Consulting says construction cost as a percentage of total capital cost for large process plants on the Gulf Coast has risen to 40-45% from 20-25% during the 1970s through the early 2000s.

Corn noted that productivity growth in the construction industry has been "nonexistent" dating back nearly 5 decades. "When you think about where we stood in 1968, where technology was in 1968-we still had slide rules, we still had drafting on paper-and we're flat. I can tell you other industries have greatly outpaced the construction industry."

As an example, Corn cited data showing that engineering hours per foot of pipe have doubled and weld inches per day have been cut in half during the past 15 years. Dahl, referencing data from Westney Consulting, said, "We're seeing a two-time increase in work hours and decline in productivity" in pipefitting and welding. The firm's regional data for the US Gulf Coast shows a 72% increase in work hours per linear foot of pipe between 1997 and 2015.

The Gulf Coast project has required as many as 10,000 engineering and construction jobs, including those of welders, pipefitters, riggers, and electricians. CPChem's web site advertises "an immediate, acute need for skilled crafts persons" for the project.

Watson noted that, with 10 mega-olefins projects and six LNG projects under construction in the US, there have been labor availability challenges and higher wages, with at least 50 hr/week standard now in the field, and per diems and retainage bonuses also rising. He believes contractors must maximize labor efficiency to reduce costs, and questions, "Are we really maximizing the amount of offsite fabrication and getting things delivered in bigger and bigger chunks?"

Richard Westney, founder and director of Westney Consulting, explained the ups and downs of the industry make it difficult to retain skilled workers, as many of their skills are not transferable to other segments of the industry. He's observed an emphasis on workforce development and examining what more can be done to encourage training of people to become welders, electricians, and pipefitters. "There's a tremendous effort along the Gulf Coast in that area, but results will take time," he cautioned.

Dahl noted the industry has lost "a lot of the basics-or the blocking and tackling-of builder-contractor organizations that know how to execute these projects, retaining skills like recruiting and training, and keeping key frontline leaders." On the owner side, impacts include late engineering and late materials showing up on site.

Given their complexity and organizational hierarchy, Ackley views projects as their own enterprise, with revenues of a Fortune 500 company, and thinks they should be treated as such. "When you think about that, your project controls manager is the CFO of a Fortune 500 company."

Near-term ethylene startups

The new wave of grassroots North American ethylene projects kicked off with this year's startup of Mexico's Braskem-Idesa ethylene complex, which receives ethane from conventional Mexico production that's priced against US shale gas. The $5.2-billion Etileno XXI project features an ethane cracker that produces a combined 1.05 million tpy of ethylene and polyethylene. It will directly compete with the several US ethylene complexes slated to come online in the new few years. Four ethylene projects in Texas are expected to start up in 2017.

Slated for commissioning early next year, Ingleside Ethylene LLC, a 50-50 JV of Occidental Chemical Corp. and Mexichem SAB de CV, is constructing a 550,000-tpy ethane cracker at OxyChem's existing plant in Ingleside, Tex. The $1.5-billion unit will process ethane feedstock from US shale gas to supply OxyChem with an ongoing source of ethylene for manufacturing vinyl chloride monomer, which Mexichem will use to produce polyvinyl chloride (PVC) resin and PVC piping systems.

CPChem's aforementioned US Gulf Coast petrochemicals project, scheduled to start up in the second half of 2017, is expected to increase the firm's global ethylene and polyethylene capacity by 30%. Dow Chemical Co.'s 1.5 million-tpy ethylene plant in Freeport, Tex., and ExxonMobil Chemical Co.'s 1.5 million-tpy steam cracker in Baytown, Tex., are also scheduled for startup in 2017.

Among five projects slated for commissioning during 2018-20 are Sasol Ltd.'s 1.5 million-tpy ethane cracker as part of its Lake Charles chemicals project in Westlake, La., near Lake Charles; and Royal Dutch Shell PLC subsidiary Shell Chemical Appalachia LLC's 1.5 million-tpy ethane cracker and three polyethylene units, with a combined production capacity of 1.6 million tpy, as part of a grassroots petrochemical complex about 30 miles northwest of Pittsburgh. The latter will utilize low-cost Marcellus and Utica shale ethane.

About a dozen more cracker projects are under study in North America. WoodMac notes that while the global ethylene production cost curve has flattened, North America "remains competitive in a $30-50/bbl oil environment. But returns on capital will be much lower for new projects than originally anticipated" before the global downturn. Corn concluded that future Gulf Coast capital project growth is threatened as chemical producers, which have always struggled with lower margins, face cost escalation and lost competitiveness, reduced advantage over other regions, and tighter capital budgets and competition for capital.

In his own presentation at the Rice forum, Stephen Zinger, chemicals senior vice-president at PCI Wood Mackenzie, said slow domestic demand growth in the US for ethylene, polyethylene, and other derivatives, coupled with the rapid expansion in capacity, means producers in the US will have to lean on exports somewhere in the supply chain to expanding international markets. Ethane on its own can be exported through new terminals in Marcus Hook, Pa., and Morgan's Point, Tex.

As for exporting the ethylene itself, "the difficulty with ethane and ethylene-and natural gas, for that matter-is that it's a cryogenic material. It's very expensive to ship and very expensive to liquefy, so it's not a cost-effective way to trade in the world," Zinger explained. The more effective solution is to trade it as a derivative such as polyethylene, which, as a pellet, can be easily shipped in containers.

LNG projects under construction

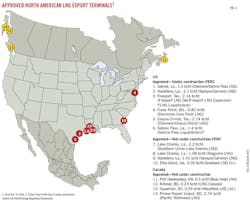

Six LNG export projects are currently under construction in the US, according to the US Federal Energy Regulatory Commission, which is responsible for authorizing the siting and construction of onshore and near-shore LNG import or export facilities (see figure). FERC counts two of those export projects as Cheniere's Sabine Pass complex, where Trains 1 and 2 commenced operations this year and Trains 3-4 are expected to start up next year.

Train 5 is under construction and expected to begin operations in 2019. Cheniere says all regulatory approvals have been received to construct and operate Train 6, and expects final investment decision to be reached once it gets contracts and financing sufficient to support construction. Production capacity of each LNG train is designed for 4.5 million tpy.

Up the Louisiana coast along the Calcasieu Channel in Hackberry sits the worksite for Cameron LNG, which is run by a JV owned by affiliates of Sempra Energy, France's Engie, Japan's Mitsui & Co. Ltd., and Japan LNG Investment LLC, a JV formed by affiliates of Mitsubishi Corp. and Nippon Yusen Kabushiki Kaisha.

Construction is under way on the $10-billion liquefaction project's first phase comprising Trains 1-3, each of which will have a capacity of 4.5 million tpy. The facility is expected to commence operations during 2018, with the first full year of operations in 2019. In May, FERC authorized Cameron to proceed with the expansion phase comprising Trains 4 and 5, each of which will have a maximum production capability of 4.985 million tpy and its own feed gas pretreatment facilities. Construction on the expansion project is slated to begin next year.

In Texas, the $12.5-billion Freeport LNG project owned by Freeport LNG Development LP started construction in November 2014 and expects to reach commercial operation of Train 1 in 2018, with Trains 2 and 3 anticipated for 2019. Each train will produce 4.64 million tpy.

Dominion Resources Inc. started construction in 2014 on its $3.4-3.8 billion single-train, 5.25-million tpy Cove Point LNG project on the Chesapeake Bay in Lusby, Md., positioned near the Marcellus and Utica, and plans to put the liquefaction facilities in service in 2017.

Another facility developed by Cheniere, Corpus Christi LNG in Texas sits at one of the firm's existing sites that was previously permitted for a regasification terminal. Construction on Trains 1 and 2 began in 2015 with completion anticipated for 2018, and the firm is continuing to market nominal production capacity from Train 3. An application was filed with FERC for Trains 4 and 5, for which Cheniere hopes to begin construction next year. As with the Sabine Pass facility, production capacity of each LNG train is designed for 4.5 million tpy.

Advancing a new LNG project

Eight more projects in the US and Canada have been approved but await construction. Another 15 in the US either have FERC applications pending or are in pre-filing. The largest of those with a pending application is the 3.6-bcfd Rio Grande LNG project to be built in Brownsville, Tex. Owner NextDecade LLC expects to receive FERC approval in February 2017 and begin construction that June. Initial LNG exports are expected to ship by yearend 2020.

Rene van Vliet, chief operating officer of NextDecade and director of his own gas- and LNG-focused consultancy, took time to correspond with OGJ via e-mail as he works to push Rio Grande LNG toward tangibility. His involvement in global LNG projects spans more than 3 decades. In light of the massive costs associated with building an LNG facility and the prospect of near-term saturation in the market once the US projects currently under construction come online, he remains confident in Rio Grande LNG's competitiveness vs. its domestic peers and those around the world.

"Our analysis, supported by many independent parties such as [WoodMac] and McKinsey [& Co.], confirms that the US is by far the lowest cost location for LNG projects currently under development and [our] project is the most competitive among all other US greenfield projects," he said. "In fact, only a few brownfield developments are slightly lower in cost thanks to existing infrastructure."

Van Vliet said the NextDecade team has a longstanding relationship with FEED and EPC contractor CB&I having worked together on various projects through the years. "NextDecade's team and CB&I's team have been working closely together in a partnership relationship rather than an owner-contractor relationship, cultivating increased two-way communication between parties," he explained. "Based on the FEED work we have now entered into an open book estimate (OBE) process for the EPC.

"NextDecade focuses on key areas with a lean owner's team specializing in project development, management, and execution. Our team works closely with CB&I and other subcontractors, consultants, and suppliers. For example, we have partnered with industry-leading consultants and subcontractors in areas including regulatory and permitting, environmental, civil, marine, air and noise modelling, compressors, rotating equipment, electrical, and instrumentation.

With construction slated to begin in less than a year, NextDecade has had "intensive discussions with CB&I about their training programs for construction labor," said van Vliet. "CB&I has been successful in recruiting and training a significant group of labor from South Texas, in particular the Rio Grande Valley, where our project will be built. Many of these workers are currently occupied on comparable CB&I projects on the Gulf of Mexico, and, as such, will be suitably prepared for our project when it moves forward. In addition, the anticipated timing of our project is advantageous as many other projects will be winding down as ours ramps up, helping to ease the strain on workforce resources.

"One of CB&I's distinguishing characteristics versus other EPC contractors is that CB&I utilizes its own construction workforce, helping to reduce cost and raise quality," he said. "CB&I does not subcontract all of its construction work and simply act as a managing contractor."

Another EPC firm with heavy LNG involvement is Fluor, whose $18.5-billion Gladstone LNG project in Australia shipped its first cargo from its second train in May. Jim Brittain, president of Fluor's energy and chemicals segment, told OGJ that his firm's measures for dealing with higher costs include the use of "extensive modularization," moving up to 70% of field hours to its offsite fabrication facilities, thereby reducing the required plot space.

"To reduce equipment costs, we source materials and equipment globally" and have seen "savings of 25 to 40%" as a result, Britain said. "We are also developing an innovative approach that drives a minimum-kit concept on a project. It challenges traditional execution methods and has an absolute focus on getting to the lowest capital cost of a facility, while still ensuring safety, quality, and operability."

Brittain said, "We see all projects globally as having capital cost constraints. No matter where a project is located geographically, we are partnering with clients early in the process to understand the project's drivers and their investment needs. We can then develop a solution, tailored to the specific project and location that leverages modularization, construction planning, and global sourcing to develop a fit-for-purpose, capital efficient solution to each project."

State of future LNG projects

With US LNG capacity ramping up over next 4 years, Zinger noted that not all of those facilities will be fully utilized due to the emerging global demand limits and competitive supply. As such, a second wave of US LNG plants will struggle to get contracts, resulting in deferrals or cancellations.

Regarding the global LNG market, van Vliet believes saturation will only be temporary. "After many years in the LNG business, we have seen the cycles of supply and demand and understand that the LNG business is about the long term. Financing of projects such as ours requires long-term contracts, typically 20-years in length, and around these foundational contracts, shorter-term and spot contracts are being developed. There is a growing consensus that demand will once again exceed supply in the early part of the next decade and that a significant amount of new supply will have to be developed and built to satisfy that demand. The Rio Grande LNG project is timed to take advantage of that shift.

"Against this backdrop we have seen a recent phenomenon that splits LNG project developers into two main categories. The first category is the group of international and national oil and gas companies that have historically developed most of the existing global LNG infrastructure. Significantly reduced revenue streams caused by low oil prices have forced these companies to make drastic capital investment cuts and reprioritize upstream, midstream, and downstream projects in their portfolio. This has led to numerous announcements deferring, shelving, or cancelling LNG projects yet to reach a final investment decision.

"Backed by investment funds and other sources of funding, a second category of LNG project developers has emerged over the last decade. These developers are less dependent on revenues from on-stream oil and gas related activities and, even under current market conditions, a number of these groups have been able to attract investors and progress the development of their projects. For these players only the fittest will survive," van Vliet said. "A number of them will not make it and we will see a fall-out of projects-project developers in this category over the next 1-2 years."