Asia-Pacific refining primed for capacity growth

Robert Brelsford

Downstream Technology Editor

Leena Koottungal

Survey Editor/News Writer

Global crude oil refining capacity in 2014 edged lower from 2013 (OGJ, Dec. 2, 2013, p. 34), according to the latest OGJ Refinery Survey. This marked a second consecutive year of decline in worldwide capacity since reaching its record high in 2012 (OGJ Online, Dec. 3, 2012, p. 32).

Refiner response rates to this year's survey were on the rise compared with recent years, but year-on-year changes to regional capacities largely resulted from inclusion of more current operating data collected independently by OGJ for operators that did not respond by the survey deadline.

Asia-Pacific was the only region to register capacity growth during 2014. While the opening of one new refinery mostly contributed to this growth, improved data collection methods by OGJ also led to the addition of another refinery missed in previous years but now reflected in the current year's survey.

Additional capacity documented to have come online during the year and discovered to be omitted from official survey results, however, means capacity gains in the region were larger than the survey reflects.

Enhanced data collection efforts amid improved survey response rates also contributed to updated information for operators in Africa and Eastern Europe. The inclusion of a previously omitted refinery already operating in Africa and updated capacity data on Eastern European refineries led to a show of capacity increases for these regions as well.

Alternatively, this year's survey results indicated a downturn in overall capacity for the Middle East, North America, South America, and Western Europe. While operators in these regions did report refinery shutdowns and some capacity reductions, lower capacities also are attributable to the availability and inclusion of more accurate data rather than actual capacity losses during the year.

For 2014, OGJ's survey data show total global capacity at slightly less than 88 million b/cd with a drop in both number of plants-by seven-and capacity-by a mere 70,000 b/cd-mostly in Western Europe and North America.

The figure shows trends in operating refineries and worldwide capacity.

Largest refining companies

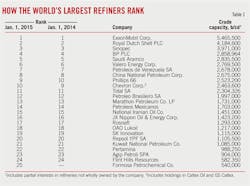

Table 1 lists the top 25 refining companies that own most worldwide capacity. Table 2 lists companies whose plants total more than 200,000 b/cd of capacity in Asia, the US, and Western Europe. Capacities from Tables 1 and 2 include partial interests in refineries that the companies do not wholly own.

Only one major change took place in Table 1 positions since Jan. 1, 2014. Formosa Petrochemical Co. replaced Sunoco Inc. as a result of Sunoco's previous divestiture of its 175,000-b/d Marcus Hook, Pa., refinery (OGJ Online, Dec. 2, 2011) and 330,000-b/d refinery in Philadelphia, Pa. (OGJ Online, July 2, 2012).

Table 2 shows refineries by region with 200,000 b/d capacity or greater. Table 3 lists the world's largest refineries with a minimum capacity of 400,000 b/cd.

Table 4 lists regional process capabilities as of Jan. 1, 2015.

Refinery additions, removals

Four new refineries make their debut in this year's survey, while seven disappear from the list.

Only one of the newly listed refineries was slated for start-up during 2014, constituting a proposed total growth of 300,000 b/d in fresh nameplate crude-distillation capacity.

In August, Indian Oil Corp. Ltd. (IOC) said it was near to commissioning its long-delayed 300,000-b/d, full-conversion refinery at Paradip, on India's northeastern coast (OGJ Online, Aug. 14, 2014). The $5-billion refinery, which began some start-up activities in early 2014, was scheduled to be completed and begin additional commissioning by December.

By late November, however, local media reported official commissioning of the refinery would not occur until late-March or early-April 2015.

Configured to process heavy and high-sulfur crude oil and to produce Euro 5-standard fuels, the Paradip refinery initially was scheduled for commissioning in November 2013 (OGJ Online, Mar. 13, 2013).

The refinery appears in the survey to reflect initial start-up processes in 2014 and because reports of its delayed full commissioning emerged after the survey was completed.

Downstream processing capacity data for Paradip, however, was not available for this year's survey. Omissions for these units in the survey reflect the lack of data availability, not zero downstream capacity.

The remaining three refineries to make their first appearance in the survey were commissioned before 2014 but not yet reflected in surveys. These include China National Offshore Oil Co.'s (CNOOC) 240,000-b/d refinery in Huizhou, Guangdong province (OGJ Online, Dec. 2, 2013, p. 34), China National Petroleum Corp. (CNPC) subsidiary PetroChina Co.'s 200,000-b/d refinery at the port city of Qinzhou in the Guangxi region near Vietnam (OGJ Online, Mar. 7, 2011; Dec. 6, 2010), and the joint CNPC-Sonatrach-owned 12,000-b/d refinery in Algeria's southern region of Adrar.

While these four refineries added more than 750,000 b/d to global crude-distillation capacity, this was offset by refinery removals from the survey, which collectively accounted for an overall loss of more than 600,000 b/d.

In February, Flint Hills Resources Alaska LLC (FHRA), a wholly owned subsidiary of Koch Industries Inc., Wichita, Kan., reported plans to cease crude oil processing at its 85,000-b/d North Pole refinery near Fairbanks, Alas., by June (OGJ Online, Feb. 10, 2014). The refinery's extraction unit was shut down on May 1, ending gasoline production, while crude unit No. 2 was shuttered by June 1, ending production of jet fuel and all other refined products.

The refinery's closure stemmed from FHRA's costs to address soil and groundwater contamination caused when the plant and the land beneath it was owned by Williams Cos. Inc., Tulsa, and the state of Alaska, respectively.

Closure of FHRA's refinery removed more than 130,000 b/d of crude-distillation capacity from the survey.

In October, Caltex Australia Ltd. officially shut down its 135,000-b/d Kurnell refinery in Sydney and converted it into Australia's largest fuel import terminal (OGJ Online, Oct. 14, 2014).

The terminal will provide about 4 million bbl of storage capacity and supply fuel to retail outlets and commercial customers in New South Wales and the Australian Capital Territory, which surrounds Canberra.

After failed attempts to sell its 135,000-b/d Milford Haven refinery in Pembrokeshire, Wales, Murco Petroleum Ltd. in November confirmed it was decommissioning the plant to be operated solely as a petroleum storage and distribution terminal (OGJ Online, Nov. 5, 2014).

The refinery's planned sale and now closure come as part of a previously reported plan by Murphy Oil Corp., Murco's owner, to divest its UK downstream operations (OGJ Online, Oct. 16, 2012).

In January, MOL Group, Budapest, began the progressive transformation of its 52,000-b/d refinery in Mantova, Italy, into a products hub, removing a total of more than 69,000 b/d in crude-distillation capacity from the survey. The refinery's closure resulted from the unfavorable economic environment Italy's refining business faces, MOL said in October 2013.

The remaining three refinery removals consist of closures OGJ missed in previous years but corrected in this year's survey. These include LyondellBasell's 105,000-b/d Berre refinery in France, PT Pertamina's 4,750-b/d refinery in the Indonesian province of Pangakalan Brandan, and Gulf Atlantic Operations LLC's 20,000-b/d refinery in Mobile, Ala.

Asia-Pacific gains

Refining capacity was on the rise in Asia-Pacific during 2014 despite a still-sluggish economy as well as a downturn in petroleum product demand. On the whole, firm operational data out of China and Japan for downstream processes, new start-ups, and plant shutdowns remained limited, with refiners in those regions maintaining a long-standing pattern of quiet openings and closings.

While official survey results this year indicate a modest increase in regional capacity, a host of ongoing and newly reported projects remain on track for start-up in the next few years despite economies that most industry analysts agree will show few signs of rising demand for petroleum products.

In April, Sino-Venezuela Guangdong Petrochemical Co., CNPC subsidiary PetroChina Co. Ltd., let a contract to Metso Corp. for advanced valve technology for use in the delayed coking process at its 20 million tonnes/year (tpy) heavy crude oil processing plant in the Jieyang Nandahai Petrochemical Industrial Zone of China's Guangdong province (OGJ Online, Apr. 10, 2014).

In terms of processing capability, the Guangdong refinery will become China's largest. The complex will contain 29 processing units as well as a 300,000-tonne crude oil terminal and a 30,000-50,000-tonne product terminal.

PetroChina in May 2008 joined Petroleos de Venezuela SA (PDVSA) to build the Guangdong refinery, which was configured to process Venezuelan heavy oil (OGJ Online, Nov. 15, 2013; Apr. 13, 2009). PetroChina (60%) and PDVSA (40%) have invested a combined $9.54 billion into the Guangdong project.

In November, CNPC and OAO Rosneft endorsed the crude refining portion of a feasibility study for construction of the long-planned Tianjin refinery, which is to be built in northern China's industrial zone of Nangang in Tianjin (OGJ Online, Nov. 10, 2014; Sept. 2, 2010). The companies also adopted a resolution to optimize the refining segment of the Tianjin project by the end of February 2015. The proposed refinery would have a crude oil processing capacity of 16 million tpy and a paraxylene production capacity of 1.4 million tpy.

Chinese investments into cleaner technologies also increased in 2014 as producers sought ways to comply with heightened environmental restrictions (OGJ, Dec. 2, 2013, p. 34). In March, Shaanxi Yanchang Petroleum (Group) Co. Ltd. (Yanchang Petro) let a contract to Yokogawa China Co. Ltd. to supply control systems for both coal-oil coprocessing and coal tar hydrogenation plant construction projects in China (OGJ Online, Mar. 26, 2014).

In Japan, a 2010 ordinance enacted by Japan's Ministry of Economy, Trade, and Industry (METI) requiring Japanese refiners to raise their mandatory cracking-to-crude distillation capacity ratio succeeded in slashing the country's refining capacity, but further cuts were likely to occur by 2018, according to a May report from Facts Global Energy (FGE; OGJ Online, May 22, 2014).

Implemented in July 2010 with the objective of improving the sophistication of Japanese refineries by April 2014, the ordinance stipulated refiners either to upgrade their heavy oil cracking units or reduce their crude distillation unit (CDU) capacities to a ratio of 13% or higher from 10% by March (OGJ Online, Dec. 3, 2012).

Based on METI's definition, the country's heavy oil cracking-CDU ratio has increased to 13.1% from 11% in April 2010. While the ordinance indeed established a deadline to which refineries ultimately adhered, FGE said reductions to CDU capacities likely stemmed from Japanese refiners' inability to justify the major investments needed to upgrade their cracking units in light of a stagnant oil products demand outlook.

METI is now planning a second phase of the ordinance that will seek further to integrate Japan's refining business with new targets for refiners to meet by the end of March 2017, which could provide incentives for refineries close to other refineries and petrochemical plants to merge or integrate, FGE said.

In January, Reliance Industries Ltd. (RIL), Mumbai, let a contract to French firm Alstom T&D's Indian division to provide power transformer packages for the continued expansion of the 1.24 million-b/d Jamnagar refining and petrochemical complex in Gujarat, India (OGJ Online, Jan. 22, 2014; July 6, 2012; May 3, 2012).

In July, India's government officially approved Hindustan Petroleum Corp. Ltd. (HPCL) to set up its proposed refinery and petrochemical complex in Barmer district, Rajasthan (OGJ Online, July 18, 2014; Mar. 14, 2013). The planned refinery, which will be established in collaboration with the government of the Indian state of Rajasthan, will have a crude processing capacity of 9 million tpy, the ministry said.

The complex, which is to be implemented by HPCL Rajasthan Refinery Ltd. (HRRL), a joint venture of HPCL and other equity partners, would use crude produced locally and from elsewhere, making it Rajasthan's first refinery and India's first petrochemical plant designed to process indigenous crude.

Mechanical construction of the project has not started, and India's central government has yet to provide an exemption in excise duty for the proposed refinery. A timetable for when construction on the complex will begin was not disclosed.

The Indian Ministry of Petroleum and Natural Gas previously estimated the Barmer project cost at $6.85 billion and construction time at 4 years (OGJ Online, Mar. 14, 2013).

In August, Bharat Petroleum Corp. Ltd (BPCL), Mumbai, let feasibility studies to Engineers India Ltd. (EIL) for projects related to the long-planned expansion of its 3 million-tpy Numaligarh refinery in the Golaghat district of Assam in far-northeastern India (OGJ Online, Aug. 13, 2014; Sept. 21, 2012).

Under the separate agreements, which were signed during the past year, EIL was to provide detailed feasibility reports for both the Numaligarh refinery expansion as well as for a 1,400-km (about 870-mile) crude oil pipeline connected to the project that would extend from the port of Dhamra on India's eastern coast to Numaligarh.

IOC confirmed in August that it had commissioned a newly upgraded fluid catalytic cracking unit (FCCU) at its 160,000-b/d Mathura refinery. The unit entered service in January (OGJ Online, Aug. 14, 2014). At a cost of $167 million, the upgrade project has increased the FCCU's processing capacity to 30,000 b/d from 20,000 b/d and maximized the refinery's production of propylene, IOC said.

In September, BPCL, through Air Products & Chemicals Inc., let a contract to Technip SA to provide project management, as well as engineering, procurement, and construction management (EPCM) services for a new industrial gas complex at BPCL's Kochi refinery at Ambalmugal in the Indian state of Kerala (OGJ Online, Sept. 12, 2014).

To be built on a "build-own-operate" basis, the gas complex will supply BPCL industrial gases (hydrogen, nitrogen, and oxygen) for the Kochi refinery's integrated expansion project (OGJ Online, July 16, 2012), which will increase the refinery's capacity to 15.5 million tpy from 9.5 million tpy and produce fuels that meet Europe's latest emissions standards.

BPCL previously let contracts for the integrated expansion to Petron Engineering Construction Ltd. and Shriram EPC Ltd. for work related to FCCUs at the Kochi refinery (OGJ Online, July 28, 2014; Nov. 19, 2013).

In November, Mangalore Refinery & Petrochemicals Ltd. (MRPL), a subsidiary of Oil & Natural Gas Corp. Ltd., commissioned the long-delayed Phase 3 expansion and upgrading at its 194,000-b/d refinery at Mangalore (OGJ Online, Nov. 13, 2014; June 8, 2010). By the close of second quarter of financial year 2014-15, MRPL had started up all new installations involved in the expansion, including the third train of a three-train sulfur recovery unit, a raw water treatment system, LPG mounded bullet storage tanks, and other related off site installations.

Earlier in the year, MRPL confirmed start-up of other units in the Phase 3 expansion, including a 2.2 million-tpy FCCU (OGJ Online, Aug. 27, 2014), a 650,000-tpy coker heavy gas oil hydrotreating unit (OGJ Online, May 15, 2014), and a 3-million tpy delayed coker (OGJ Online, Apr. 4, 2014).

Reported in February 2010, the Phase 3 expansion was designed to increase the refinery's complexity and profitability by increasing refining capacity to 300,000 b/d as well as equip the plant to process lower-cost heavy, sour, and high-TAN crudes, MRPL said.

In August, Pakistan's National Refinery Ltd. (NRL) let a contract to China National Chemical Engineering Corp. Ltd. (CNCEC) for work related to the upgrade and expansion of its refining complex in the Korangi Industrial Zone, about 9 miles southeast of the center of Karachi (OGJ Online, Aug. 19, 2014). CNCEC's scope of work will include installation of a high-sulfur diesel desulfurization plant and isomerization plant, as well as associated units.

Designed to help the plant meet Euro-2 environmental standards, the diesel desulfurization unit is scheduled to be commissioned by end-December 2015, NRL said in its latest corporate environmental report. The naphtha isomerization project, which will increase production of motor gasoline by 192,000 tpy also, is due to start up by yearend, according to NRL.

Additional proposed elements of the revamp at the Karachi complex, which consists of two lube refineries and one fuel refinery with a combined crude oil processing capacity of 2.9 million tpy, includes work to expand processing capacities at the complex.

At its Lube 1 refinery, NRL plans to increase installed crude oil processing capacity to 17,000 b/sd from its current capacity of 12,050 b/sd, as well as to expand its vacuum fractionation capacity to 6,600 b/sd from 5,200 b/sd. Engineering design for this project component is completed, with the project likely to be commissioned next year.

At its fuel refinery, NRL said it intends to lift installed processing capacity at the crude distillation unit to 53,000 b/sd from its current capacity of 50,000 b/sd. In 2012, the company said it expected this element of the revamp project to be completed by December 2015.

In mid-March, Pakistan Refinery Ltd. (PRL) let a contract to Honeywell's UOP LLC, Des Plaines, Ill., for process technology and modular equipment at its 47,110-b/d refinery along the coastal belt of Karachi (OGJ Online, Mar. 18, 2014).

Honeywell will deliver a UOP Penex process technology unit in modular form to PRL, which the refinery will use to produce isomerate-a high-value gasoline blending component-and to convert currently exported volumes of naphtha into high-octane gasoline.

The Penex unit will process 5,000 b/d of light naphtha and is intended to help PRL meet growing domestic demand for gasoline. The unit is to be commissioned by mid-2015.

In Vietnam, Nghi Son Refinery & Petrochemical LLC, through a contractor, let a contract in August to a subsidiary of Foster Wheeler AG for the design and supply of a carbon monoxide incinerator package for a residue FCC (RFCC) at its 200,000-b/d refinery and petrochemical complex in Thanh Hoa province (OGJ Online, Aug. 22, 2014). The $9 billion Nghi Son refinery, currently under construction (OGJ Online, Dec. 2, 2013), will process Kuwaiti crude oil and is to begin operating in 2018.

The refinery is a joint venture of PetroVietnam 25.1%, Idemitsu Kosan Co. Ltd. 35.1%, Kuwait Petroleum Europe BV 35.1%, and Mitsui Chemicals Inc. 4.7%.

In January, Vung Ro Petroleum Ltd. (VRP) let a services contract to Ineos for a 900,000-tpy polypropylene project at its grassroots refinery in Hoa Tam Commune in the Dong Hoa district of Phu Yen province. The VRP grassroots refinery project-a $4-billion refinery, petrochemical, and seaport development fully financed by foreign investors-will have an 8-million tpy capacity for processing VRP Blend and Arabian Light crudes into products satisfying both Vietnamese and international specifications and standards, according to VRP's web site. VRP plans to commission the refinery in 2018.

Elsewhere in the region, BP Australasia in April reported the imminent closure of its 96,850-b/d Bulwer Island refinery at Brisbane (OGJ Online, Apr. 2, 2014). The plant is slated for a mid-2015 shuttering.

Confirmation of BP's Brisbane closure came on the heels of Shell Australia's announcement in February of the sale of its 118,000-b/d Geelong refinery in Victoria and its network of 870 retail outlets across the country to Dutch group Vitol for $2.9 billion (Aus.; OGJ Online, Feb. 21, 2014).

Shell's sale of its Australian downstream assets follows the closure of its 79,000-b/d Clyde refinery at Sydney in 2012 (OGJ Online, June 7, 2012). The deal is part of Shell's global shift away from downstream. It has already sold refineries in the UK and some mainland European countries as well as made other divestments in Egypt, Spain, Greece, Finland, and Sweden.

Out of Korea, S-OIL Corp., Seoul, in early March let two contracts to a unit of Foster Wheeler for residue upgrading at S-OIL's 669,000-b/d Onsan refinery in Ulsan, South Korea (OGJ Online, Mar. 12, 2014).

Under one contract, Foster Wheeler will provide front-end engineering and design for the residue upgrading project, which will include the addition of a residue hydrodesulfurization unit, an RFCC, and multiple downstream upgrading units to enable the refinery to produce higher value products and maximize production of polymer-grade propylene.

In addition to the FEED contract, S-OIL also awarded Foster Wheeler a contract to prepare the tender for the EPC phase of the Onsan upgrade, which will include procuring long-lead items, evaluating EPC bids, and preparing a cost estimate to support S-OIL's final investment decision.

In February, PT Kreasindo Resources Indonesia (KRI) and Iran's Nakhle Barani Pardis Co. (NBP), Tehran, entered an agreement for the planned construction of a grassroots refinery in Indonesia (OGJ Online, Feb. 18, 2014). Designed to process heavy crude oil, the proposed 300,000-b/d refinery would be in either West Java or Banten province. KRI would own 70% of the planned refinery, with NBP owning the remaining 30% and acting as the refinery's heavy crude supplier.

The companies estimate the project will require an investment of $3 billion, which is based on an initial capacity of 150,000 b/d. But with both the feasibility and site selection studies still to be completed, a specific timeframe for the project has not been disclosed.

In May, PT Pertamina of Indonesia selected Axens to develop a feasibility study for the modernization and capacity expansion of the state-owned oil company's Plaju refinery in Palembang, South Sumatra (OGJ Online, May 20, 2014).

In undertaking the modernization, Pertamina aims to improve both the gross refining margin and competitiveness at Plaju by increasing the plant's flexibility to process sour crudes and boost production rates of Euro 4-standard gasoline and diesel to help satisfy India's rapidly growing domestic demand for motor fuels.

This latest feasibility study follows Pertamina's previously reported plans to modernize five of its exiting Indonesian refineries to enable the plants to process growing imports of heavy, low-sulfur crude oil as Indonesia's domestic crude production continues to decline (OGJ Online, Dec. 2, 2013; Oct. 7, 2013).

In February, Singapore Refining Co. Pte. Ltd. (SRC) let a construction contract to JGC Corp. for expansion work at its 290,000-b/d Jurong refinery in Singapore (OGJ Online, Feb. 4, 2014). JGC will perform the EPC work for a 26,000-b/d gasoline desulfurization unit, an amine treating unit, a heavy naphtha splitter, and a two-train 72-Mw cogeneration unit.

The project is to be commissioned by first-half 2017. Once in operation, the cogeneration unit and naphtha splitter will enable SRC to produce motor gasoline meeting Euro 4 and 5 specifications under more energy-efficient conditions.

Malaysia's state-owned Petronas in August confirmed the award of 11 major contracts related to milestones in the development of its refinery and petrochemical integrated development (RAPID) complex at Pengerang in southeastern Johor, Malaysia (OGJ Online, Aug. 11, 2014). Five of the contracts are for EPC and commissioning (EPCC) for RAPID's refinery and steam cracker component, while the remaining six contracts involve construction of the project's related infrastructure.

Petronas said it currently estimates RAPID will cost $16 billion, while associated installations for the project will involve an additional investment of about $11 billion (OGJ Online, July 25, 2014). RAPID's refinery start-up is to take place by early 2019.

In November, Petronas reached a deal with a subsidiary of Phillips 66 to acquire full ownership of Malaysian Refining Co. Sdn. Bhd. (MRC), which operates one of two refining trains included in Petronas's 200,000-b/d refinery complex in Sungai Udang, Melaka state, Malaysia (OGJ Online, Nov. 12, 2014). Petronas, which already owns 53% of MRC, will pay Phillips 66 Asia Ltd. $635 million in cash for its 47% stake in refinery. The sale is to close on Dec. 31.

The company's Melaka refinery houses two refining trains, PSR-1 and PSR-2. PSR-1 is owned and operated by subsidiary Petronas Penapisan (Melaka) Sdn. Bhd. and can process 100,000-b/d sweet crude and condensates, according to Petronas's web site. The MRC joint venture owns and operates PSR-2, which can process 100,000-b/d of sweet and sour crudes.

In May, Oman Oil Refineries & Petroleum Industries Co. (Orpic) signed a $2.8 billion loan agreement with a consortium of 21 international and national financial institutions to help fund the company's projects, including the Sohar Refinery Improvement Project (SRIP), which will be 65% debt financed (OGJ Online, May 1, 2014).

A brownfield project, SRIP includes a major technical improvement to the existing 116,400-b/d Sohar refinery.

As part of the project, SRIP will improve the RFCC feed quality.

In addition to the revamped RFCC, the SRIP will involve integrating five new units at the refinery, including a hydrocracker and coker, which will boost crude throughputs by 70% by adding 82,000 b/d of new OEB crude oil processing capacity to achieve a total refining capacity of 198,000 b/d.

Once completed, Orpic said SRIP will eliminate fuel oil yields from the refinery entirely as well as increase the plant's product yields for diesel (90%), gasoline (37%), jet fuel (93%), LPG (91%), naphtha (175%), and propylene (44%).

In October, Petron Corp., Mandaluyong City, Philippines, started up major units that form part of the $2 billion Refinery Master Plan 2 (RMP-2) upgrade at its 180,000-b/d Bataan refinery at Limay (OGJ Online, Oct. 14, 2014). The company commenced crude oil feed into the new Vacuum Pipestill 2 on Sept. 30.

RMP-2, which includes a total of 19 new units, is to begin full commercial operation by early 2015 (OGJ Online, Sept. 23, 2014; Jan. 17, 2012).

Americas, EMEA keep up

Elsewhere in the world, refiners' previous plans to bring on additional capacity remained in place even as slower economic growth continued to reduce global oil demand (OGJ Online, Oct. 20, 2014).

In North America, steadily rising shale crude production spurred a variety of planned capacity additions as US refiners raced to increase crude processing flexibility as they awaited clarification on the future of US crude oil export policy (OGJ Online, June 25, 2014).

Late in 2013, BP PLC reported it had commissioned all new and reconfigured units in the modernization of its 413,000-b/d refinery at Whiting, Ind. (OGJ Online, Dec. 18, 2013). The project included a 102,000-b/d coker, a reconfigured 250,000-b/d crude unit, a new 105,000-b/d gas oil hydrotreater, and associated units.

The upgrades allow the Whiting refinery to process heavy, sour crude at more than 80% of its feedstock slate. Before the project, the low-quality crude could represent only about 20% of the refinery's feed.

As of November, construction still was under way on Dakota Prairie Refining LLC's planned 20,000-b/d diesel refinery in North Dakota (OGJ, Dec. 2, 2013, p. 34). Calumet Specialty Produces Partners LP, Indianapolis, together with its 50-50 joint venture partner in the project, MDU Resources Group Inc., Bismarck, anticipated mechanical completion of the project by yearend 2014 with production ramp-up during first-quarter 2015, according to Calumet's earnings report for third-quarter 2014 .

The Dakota Prairie plant, to be the state's second refinery, will sit on 318 acres west of Dickinson, Stark County, in southwestern North Dakota.

Husky Energy Co. approved a $300 million upgrade project at its 161,500-b/d Lima, Ohio, refinery to boost the plant's ability to process increased volumes of heavy crude from western Canada (OGJ Online, Feb. 2, 2014). The crude oil flexibility project will increase heavy crude processing capacity at the refinery by as much as 40,000 b/d starting in 2017.

Engineering work on the project currently is under way, and equipment upgrades at the refinery are to occur during planned turnarounds in late-2015 and late-2016.

In November, Brazil's National Petroleum Agency (ANP) authorized Petroleo Brasileiro SA (Petrobras) to commission units at its Abreu e Lima refinery (Rnest) at the port of Suape, near Recife, the capital of Pernambuco state (OGJ Online, Nov. 19, 2014).

Petrobras started up the first 115,000-b/d phase at Rnest, which includes atmospheric distillation, caustic treatment, and naphtha hydrotreating units on Nov. 17. The company also began operating Rnest's first train of six tanks, which have a combined storage capacity of more than 500,000 cu m.

Once Rnest's second 115,000-b/d phase enters operation, which is scheduled for 2015 (OGJ Online, Nov. 6, 2014), the refinery will have the capacity to process 230,000 b/d of 16° API crude for the production of mainly low-sulfur diesel, but naphtha, petroleum coke, LPG, and heavy coker gas oil as well.

Rnest does not appear in OGJ's current survey because start-up was reported after the survey was completed.

Construction also started for the long-planned expansion and modernization at PDVSA's 190,000-b/d Puerto La Cruz refinery in eastern Venezuela (OGJ Online, July 21, 2014; July 1, 2014). PDVSA let a $4.8 billion contract for the revamp to a Hyundai Engineering & Construction Co. Ltd.-led consortium that also includes Wison Engineering Services Co. Ltd.

The entire expansion and modernization at Puerto La Cruz, which will entail the remodeling of existing installations and equipment at the refinery as well as some construction to improve the yield of higher-quality products from a heavier slate of crude oil feedstocks, will last 47 months from initial groundbreaking.

Elsewhere, Hovensa LLC, the joint venture of Hess Corp. and PDVSA, found a buyer that plans to restart its 500,000-b/d refinery on the island of St. Croix, US Virgin Islands (OGJ Online, Oct. 29, 2014; Sept. 3, 2014; Jan. 18, 2012).

Both the owners of Hovensa and the government of the Virgin Islands have reached separate, tentative agreements for the sale and operation of the refinery with Atlantic Basin Refining Inc. (ABR), a company formed specifically to acquire the complex.

In November, however, the Senate of the 30th Legislature of the US Virgin Islands voted unanimously to send back a proposed operating agreement formed between the government and ABR to the legislative body's finance committee for further review (OGJ Online, Nov. 14, 2014). No timetable was disclosed for when legislators might approve or reject the agreement.

Should the sale proceed, ABR plans to reconfigure the refinery to process US light, sweet crude, which would resolve many of the problems faced by the complex's former owners, who were obligated to process heavy, sour Venezuelan crude.

The reconfigured St. Croix refinery is to have an initial crude processing capacity of 300,000 b/d.

In Canada, North West Redwater Partnership (NWR) continued to let contracts to Jacobs Engineering Group Inc. for additional work at NWR's greenfield bitumen refinery in Sturgeon County, about 45 km northeast of Edmonton, Alta. (OGJ Online, Oct. 28, 2014; Mar. 11, 2014).

Once completed, Phase 1 of the $8.5-billion project will have a processing capacity 50,000 b/d and capture 1.2 million tpy of carbon dioxide to be sold for use in enhanced oil recovery. Two further phases with capacities of 50,000 b/d each also are planned for the refinery.

Following commissioning of all three phases, the Sturgeon refinery will operate at a capacity of 150,000 b/d to produce diesel, diluent, and other bitumen products for both Canadian and global markets.

NWR, a joint venture of North West Upgrading Inc. and Canadian Natural Upgrading Ltd., a wholly owned subsidiary of Canadian Natural Resources Ltd., previously said it plans to commission commercial operations for Phase 1 in September 2017 (OGJ Online, Mar. 3, 2014).

In the Middle East, Iraq in February started construction on a long-planned refinery in southern Karbala province (OGJ Online, Feb. 26, 2014). The planned 140,000-b/d Karbala plant, which will contain more than 20 processing units to produce LPG, gasoline, gas oil, fuel oil, jet fuel, and asphalt meeting international standards equivalent to European production, will serve growing domestic Iraqi demand, Iraq's Minister of Oil Abdulkareem Liaybi said.

The Karbala project is part of Iraq's longer term plan to construct four refineries to add 750,000 b/d of refining capacity. The additional planned projects include a 300,000-b/d Nassiriya refinery as well as two additional refineries in Maysan and Kirkuk, each with a capacity of 150,000 b/d (OGJ Online, June 4, 2013).

Abu Dhabi Oil Refinery Co. (Takreer) let a contract to Metso Corp. to supply valve technology for a carbon black and delayed coking plant currently under construction at its 350,000-b/d Ruwais refining complex about 385 miles west of Abu Dhabi City in the United Arab Emirates (OGJ Online, Apr. 28, 2014). Scheduled for completion in December 2015, the plant will process 30,000 b/d of crude and produce 40,000 tpy of carbon black.

Takreer previously reported a $10-billion expansion of the Ruwais refinery that will add 417,000 b/d of crude capacity, taking the plant to more than 800,000-b/d capacity. The company last year said it expected to start up in first-half 2014, but details of a commissioning could not be confirmed by presstime (OGJ Online, Dec. 2, 2013).

After leading global capacity contraction in 2013, European refiners remained under pressure during 2014, with projects emerging aimed at optimizing operations rather than halting them altogether.

France's Total SA, through a contractor, let a contract to GE Oil & Gas, Houston, part of General Electric Co., for work related to the expansion of its 338,000-b/d refining and petrochemical complex in Antwerp, Belgium (OGJ Online, Sept, 24, 2014).

GE will provide a variety of compressors for a refinery off-gas (ROG) expansion, which is part of Total's $1.3 billion overall investment to expand and enhance processing capabilities at the complex.

GE's equipment is scheduled for delivery to the refinery during third-quarter 2015 to support the start-up of Total's expanded ROG installation, which is to be commissioned in early 2017.

Total previously let a contract to a subsidiary of Maire Tecnimont SPA, Milan, to provide EPC services for the Antwerp ROG project (OGJ Online, Apr. 3, 2014).

In July, ExxonMobil Corp. reported it will invest $1 billion to install a delayed coker at its 320,000-b/d Antwerp refinery. The unit will convert heavy, higher sulfur residual oils into transportation products such as marine gas oil and diesel fuel.

While European refiners are experiencing weak margins and industry-wide losses as a result of excess refining capacity amid diminished demand, ExxonMobil said its investment for the coker at Antwerp will directly address a shortfall in regional refiners' capability to convert fuel oil to products such as diesel.

Along with a recently completed 130-Mw cogeneration unit and a diesel hydrotreater, the addition of the coker will bring the company's total investments into the Antwerp complex to more than $2 billion in less than a decade.

In October, ExxonMobil let an EPC contract to a subsidiary of Foster Wheeler for the upgrade of a resid unit at the Antwerp refinery (OGJ Online, Oct. 22, 2014). ExxonMobil previously reported plans to increase production of ultralow-sulfur diesel at the refinery in December 2008 (OGJ Online, Oct. 21, 2010; Jan. 9, 2009).

In Africa, Angola's state-owned Sonangol continued construction on its Sonaref refinery in Lobito, in Benguela province (OGJ, Dec. 2, 2013, p. 34). The refinery, estimated to cost $8 billion, will process Angolan crude oil to produce unleaded gasoline, diesel, jet fuel, kerosine, LPG, and small amounts of sulfur, local media reported. The refinery remains on schedule for start-up in late 2015 or early 2016 and will eventually reach a capacity of 200,000 b/d, the company said.

Nigerian conglomerate Dangote Group officially entered an agreement with Engineers India Ltd. (EIL) for PMC and EPCM for a grassroots refinery and polypropylene plant in Nigeria (OGJ Online, June 19, 2014; Nov. 25, 2013).

EIL will provide project PMC and EPCM services for implementing the 400,000-b/d refinery and 600,000-tpy polypropylene plant in in Lekki Free Trade Zone near Lagos, Nigeria , EIL said.

Dangote Group earlier had planned to locate the refinery and petrochemical project in the free-trade zone of Nigeria's Ogun state (OGJ Online, June 17, 2014).

The refinery project will include a crude distillation unit, single-train RFCC, diesel hydrotreating, continuous catalyst regeneration, alkylation, a polypropylene unit, as well as utilities and off sites, including a captive power plant and associated infrastructure.

The announcement of the EIL contract follows African Development Bank's June 13 approval of a $300 million loan to Dangote Group for the construction and operation of both the greenfield petrochemical complex and a fertilizer manufacturing plant (OGJ Online, June 17, 2014)