First of new Nomad-class desert rigs heads to Algeria

BP Exploration (Algeria) Ltd. has chosen a newly designed desert rig to drill in the Illizi basin. The operator has given a 1-year, extendable contract worth about $16 million to international drilling contractor KCA Deutag GMBH.

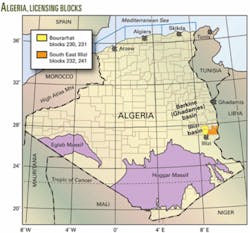

Rig fabrication and engineering company Bentec Drilling and Oilfield Services and KCA Deutag designed and completed the first of the Nomad Class rigs, Rig T-211, in July (Fig. 1). The rig is now en route to southeastern Algeria, where it will be used to drill in the South East Illizi and Bourarhet South blocks for BP in association with Sonatrach, Algeria’s national oil company (Fig. 1).

Both KCA Deutag and Bentec are wholly owned subsidiaries of Aberdeen-based Abbot Group PLC.

Algeria

BP is involved in two major gas projects in Algeria, Africa’s second-largest country by area, in partnership with Sonatrach and Statoil ASA: In Salah gas in the southern Sahara, and In Amenas, in the Illizi basin of southeastern Algeria, near Libya. BP Algeria is also exploring three areas awarded in Algeria’s sixth international licensing round, April 2005:

- Hassi Matmat in the Benoud (Oued Mya) basin, adjacent to giant Hassi R’Mel gas field (OGJ Online, June 23, 2006).

- South East Illizi and Bourarhat South, in the Illizi basin, adjacent to the In Amenas project (OGJ, Apr. 25, 2005, p. 50).

In 2003, BP Algeria’s then-President and CEO David Nagel said BP was working in Algeria because the country has the resources (9.2 billion bbl oil reserves, roughly equaling Norway and twice as much as Angola); it’s well positioned (second largest supplier of gas to Europe and a leading exporter of gas to the US); and it has a “world-class oil and gas infrastructure” (extensive pipeline system, distribution, gasification, LNG facilities).1

BP Algeria Drilling Manager Lina M. Serpa told OGJ that Rig 211 will start operating in the Bourarhet South exploration blocks acquired by BP in the 6th licensing round. “The wells to be drilled will test important exploration concepts, which, if successful, will impact follow-on activities in the block and surrounding areas. Our current priority is preparing to safely execute the first well” and to optimize additional drilling options. BP’s Algerian management team also includes Jens Pace, exploration director, and Gerry Peerebom, head of country based in Algiers.

KCA Deutag worked in Algeria from 1994-2001 for Anadarko, BHP, CEPSA, Repsol YPF, and Sonatrach.

Under the contract signed with BP in 2006, KCA Deutag will begin operating the new T-211 Nomad rig in fourth-quarter 2007. KCA Deutag operates 22 rigs elsewhere in Africa: Libya (15), Nigeria (5), and Gabon (2).

In July 2005, Algeria approved newly liberal energy regulations that reduced Sonatrach’s role in the oil and gas sector and gave foreign energy companies more scope to invest and produce hydrocarbons, although it was never implemented. Within a year, the country announced pending revisions, which were finalized in September 2006, and seem to pertain mainly to oil.2

The new amendments, introduced by Algerian President Abdelaziz Bouteflika, limit foreign participation in exploration and production and impose a windfall tax on surplus profits. Sonatrach is required to hold a minimum 51% stake in all exploration and production ventures. The new tax of 5-50% is levied whenever Brent crude trades higher than $30 (OGJ, Oct. 23, 2006, p. 5).

Sonatrach, based in the Mediterranean port town of Boumerdes, expected to earn $52-54 billion in 2006, up from $41 billion in 2005. It expected its foreign partners to earn $6 billion in 2006, up from $4 billion in 2005.2

Anadarko Petroleum Corp., Royal Dutch/Shell PLC, BHP Billiton Ltd., ENI SPA, and Hess Corp. have oil operations in Algeria. Gulf Keystone Petroleum Ltd. picked up licenses for several blocks in 2005.

Illizi basin

The Illizi basin is one of two basins within the East Algerian syncline, separated from the Berkine (Ghadames) basin by the Ahara ridge. The nearly complete sedimentary section lies unconformably on Precambrian basement. About 10,000 ft of Paleozoic sediments outcrop on the southern margin of the Illizi basin, forming the Tassilis (sandstone plateaus) of Hoggar. Mesozoic formations outcrop in the center of the basin, and the Tertiary section is seen at surface in the northwest.3

BP is exploring Bourarhat South Blocks 230 and 231 (5,304 sq km) and South East Illizi Blocks 232 and 241 (5,640 sq km), adjacent to the Libyan border, as shown on map. According to Algeria’s Ministry of Energy and Mining, the Bourarhat South blocks have been tested with 15 exploration wells, a drilling density of about 2.8 wells/1,000 sq km. About 40 wells have been drilled in the South East Illizi blocks, including 14 exploration wells, a density of about 7 wells/1,000 sq km.

Rig design

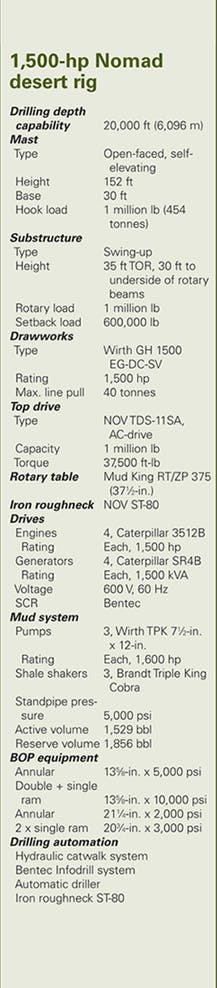

Bentec and KCA Deutag engineers developed the Nomad Class rig design in 4 months and incorporated input and suggestions from several operators working in North Africa’s Sahara Desert (Fig. 2). KCA Deutag Project Manager Ron Klunder told OGJ that the final design concept was broadly in line with BP’s rig specification and only a few modifications were necessary to comply with BP’s requirements.

Intended for desert terrain in North Africa and the Middle East, the rig is fast moving and optimized for underbalanced drilling and cluster-bay drilling operations. The 1,500-hp Nomad rig is designed to move up to 10 km between well locations over flat terrain in only 5 days, about half the time required for existing rigs, said Klunder.

He told OGJ that specific design features are responsible for the new rig’s increased mobility:

- Drill floor and substructure can be moved as a single load.

- Mast is raised with automated driller and emergency generator set.

- Mast can be moved as a single load including top drive.

- Generator packages and SCR houses are trailerized.

- Mud-treatment package and water tanks are skid-mounted.

- Special cabling arrangements simplify hookup.

The Nomad design incorporates equipment for safe and efficient operations, such as a catwalk pipe-handling system, anticollision system, iron roughneck, man-riding winch, automated driller, electronic mud pump pop-off valve savers, and dedicated equipment maintenance platforms. Special noise insulation for the generator packages is work-environment friendly, says KCA Deutag.

The 152-ft tall, self-elevating mast is newly designed by Bentec, rated to support a 1 million lb static hook load and theoretically capable of drilling to 20,000 ft (see accompanying box). The mast accommodates a NOV TDS-11SA AC-powered top drive, which remains in place and is raised and lowered with the mast (Fig. 3)

The rig also has an assisting Mud King 37½-in. rotary table, powered by two 45-kw AC motors. The 1,500-hp Wirth drawworks have a maximum line pull of 40 tonnes and a Baylor 6032 eddy-current brake.

Power comes from four Caterpillar 3512B engines, each 1,500 hp, and four Caterpillar SR4B generators (1,500 kv amp). The SCR (silicon-controlled rectifier) unit is Bentec’s custom design.

The mud system includes three Wirth TPK pumps, each 1,600 hp, and three Brandt Triple King Cobra shale shakers. The active mud system accommodates 1,529 bbl with an additional 1,846-bbl reserve. Wirth GMBH is based in Erkelenz, Germany, and Brandt is a division of National Oilwell Varco.

Blowout prevention equipment includes a 13 5/8-in., 5,000 psi annular BOP; 13 5/8-in., 10,000 psi double and single ram BOPs; 21¼-in., 2,000 psi annular BOP; 21¼-in., 2,000 psi single ram BOP, and two 20¾-in. x 3,000 psi single ram BOPs.

KCA Deutag’s Claus Chur, director technical and procurement, said the Nomad Class rigs are “equipped with special carriages [that] allow the derrick and drill floor substructure to be moved as complete assemblies over flat terrain” (Fig. 4).

The substructure is a “swing-up” type, measuring 35 ft to the top of rotary table and 30 ft to the underside of the rotary beams. It has a setback load of 600,000 lb.

Bentec designs and manufactures drilling and workover rigs and mechanical and electrical rig components at its headquarters in Bad Bentheim and a nearby yard in Nordhorn, Germany. Bentec builds about eight complete rigs/year. In 2005-06, it built SCR units and mud systems for four rigs sent to Algeria by the European Drilling Rig Alliance (OGJ, Aug. 14, 2006, p. 39).

A second Nomad Class rig, T-212, will be completed in September.

References

- Nagel, David, “Algerian Energy Sector: what now?” lecture, Washington, DC, June 26, 2003, http://www.mem-algeria.org/actu/comn/doc/david_nagel.htm.

- Chikhi, Lamine, “Algeria unveils limits to foreign oil role,” Reuters, International Business Times, Sept. 9, 2006.

- Algerian geology, Algeria’s Ministry of Energy and Mining, http://www.mem-algeria.org/hydrocarbons/geology.htm.