WITSML emerging as international industry standard

WITS committee charter: "To define the format and information content of the data stream transmitted from a wellsite to a central site by telecommunications facilities or hard media"

Wellsite Information Transfer Standard Markup Language (WITSML) is an emerging international data exchange standard. It brings the industry one step closer to enabling the shared earth model (SEM), that has been under development at oil and gas companies worldwide (OGJ, Nov. 30, 1998, pp. 58-62).

With increasing focus on collaborative asset teamwork, particularly with real-time data, companies are trying to optimize decision-making, improve drilling success, and reduce drilling costs. This requires the development of innovative IT technology to facilitate interoperability among proprietary software, as well as development of new workflow processes.

The initial goal of the WITSML project was to enable the "right-time seamless flow of wellsite data between service companies and operators to speed and enhance decision-making."1 More specifically, the project seeks "to provide an improved oil industry standard to enable the service company on the wellsite to seamlessly exchange data with the software system in the oil company office, regardless of its origin, during wellbore construction, planning and execution phases."2

WITS, the precursor

Wellsite Information Transfer Specification (WITS) was designed, implemented, and established as an industry standard format for transferring wellsite drilling data in the 1980s. It has been used by the industry for more than 20 years to share information and to provide data to remote monitoring facilities.

Prior to WITS, operating and service companies had developed many different proprietary formats and software for encoding and decoding wellsite data. There was no simple interoperability, and the maintenance of the software, format-matching, and custom modifications were continuing, significant expenses.

In addition, much useful rig data were lost or were not readily available that would have been useful in evaluating rig performance, drilling monitoring, and formation evaluation.

The charter of the WITS committee, which consists of operating and service company representatives, was to define "the format and information content of the data stream transmitted from a wellsite to a central site by telecommunications facilities or hard media."3

Service companies initially participating in the WITS steering group were Baker Hughes INTEQ, Schlumberger Ltd. (Anadrill), Halliburton Co., Sperry-Sun, and MD Totco (a Varco company).

Among the operating companies that have utilized the WITS data standard were Amerada Hess Corp., Amoco Oil Co., ARCO, BHP Petroleum Pty. Ltd., BP PLC, Chevron PNG, Conoco Inc., Corpoven, an affiliate of Petróleos de Venezuela SA (PDVSA), I.E. du Pont de Nemours & Co. (DuPont), Elf Aquitaine SA, Exxon Corp. and Esso, Gulf of Suez Petroleum Co. (GUPCO), Japan National Oil Corp. (JNOC), Kuwait Foreign Petroleum Exploration Co. (KUFPEC), Mærsk Olie & Gas AS, Maraven (PDVSA affiliate), McMoRan Exploration Co., Mobil Oil Corp., Norsk Hydro AS, Occidental Petroleum Corp., Phillips Petroleum Co., Saga Petroleum AS, Royal Dutch/Shell Group, Soekor (Pty.) Ltd., Statoil ASA, and Woodside Petroleum Pty. Ltd.

The basic framework for WITS is the Log Information Standard (LIS), a de facto standard in the wireline logging industry (OGJ, Feb. 14, 1994, p. 63).

There are 25 standard WITS data records, covering many areas of rig operations (Table 1). WITS data are returned in one of two unit systems: FPS (foot, pound, second; common US oil field units) or metric units.

Most WITS data streams are transmitted via serial interfaces, TCP/IP network sockets, or as discrete files on magnetic or optical media. Statoil was one of the first companies to employ fiber-optic cable for WITS data transmission from its Heidrun tension leg platform in the Norwegian North Sea (world's first concrete TLP; 350-m water depth).

Among the limitations of the WITS specification are:2

- Outdated MWD data records.

- Restrictions on the number of drillstring and casing sections.

- Inflexible data handling for different units of measurement.

- Limited capacity to handle static well information.

- Essentially a data push from the rig with little capability to request "pull" specific information.

Parallel industry initiatives

Another industry effort at standardization was the Open Spirit Alliance (OGJ, June 14, 1999, p. 30). This collaboration of exploration and production companies and software development companies officially formed on July 1, 1997, "cooperating to establish a software platform which enables close interoperability between applications in a multi-vendor environment."4

The initial alliance members were Shell, Elf, Chevron, Statoil, British Gas PLC, Compagnie Generale de Geophysique (CGG) Petrosystems, Jason Geosystems BV, Shared Earth Technologies, Inc., de Groot-Bril Earth Sciences (dGB), Foster Findlay Associates Ltd., and IBM. They were joined by Petrotechnical Data Systems, Institut Français du Pétrole (IFP), Schlumberger Geoquest, and Petroleum Geoservices ASA (PGS), Oslo (OGJ, Feb. 15, 1999, p. 24).

Open Spirit E&P component framework software was developed by Prismtech Ltd., Gateshead, UK, based on the Petrotechnical Open Standards Consortium, Inc. (POSC) Epicentre standard. It was distributed to Open Spirit Alliance members.

Materials developed by the alliance and Prismtech became the basis for Sugar Land, Tex.-based OpenSpirit Corp., an independent software company formed on July 1, 2001, as a joint venture of Chevron USA Inc., Shell, and Schlumberger. Prismtech focuses on developing a platform-independent application and integration framework supporting dynamic real-time application collaboration.5

WITSML is a technology envisioned by the Open Spirit Alliance discussions and POSC common data model in that it is used by "compliant applications to share data without the need for data exchange and reformatting programs."4

Statoil and DART

In 1997, Statoil began to envision a system that would allow the company to transfer real-time data from several contractors' proprietary systems. Statoil initially linked data from Sperry-Sun Drilling Services' Insite drilling information system via satellite to UNIX-based software in its office. This led to the development of the Drilling Automation Real Time (DART) system and DART Link, which handled data transfer.

The DART standard was more flexible than WITS. DART returned data in SI units, offered more options for returning data in different ways from the database, and was more rigorous in specifying well positions than WITS.

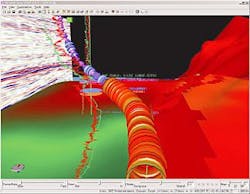

A practical application arose when Statoil participated in the Sincrudos de Oriente Sincor CA (Sincor) joint venture and utilized that system to accurately geosteer horizontal wells in Venezuela. The next application came in October 2000, when Statoil's Heidrun asset team began using DART Link to help drill increasingly demanding wellbores (Fig. 1). The Heidrun team used DART Link on 30 wells drilled between October 2000 and the end of 2002.

As DART and DART Link developed in parallel with WITSML, Statoil moved to the emerging WITSML standard and replaced DART Link with WITSML-enabled OpenWire, developed by Landmark Graphic Corp. (Fig. 2).

Evolution to WITSML

Landmark's David Field said last year, "The old WITS binary file format had evolved into so many flavors, there was no real standard, no interoperability between rig-side data acquisition systems and onshore interpretation systems. So all these operators and service companies sat down together and came up with WITSML."6

Enter the 21st Century.

null

The WITSML project began in October 2000, initially sponsored by BP and Statoil, and later by Shell and ExxonMobil Corp. Major service companies were involved from the beginning, including Baker Hughes Inc., Norwegian Petroleum Society (NPS), Halliburton, Landmark, Schlumberger (and initially Geoquest). Paradigm Geophysical Ltd., IMS, Petrolink Services Ltd., Sense Technology AS, and SDC Geologix Ltd., facilitated by POSC, joined them.

WITSML is intended as a standard format for drilling data. It also defines an application programming interface (referred to as the "API"), which allows software developers to build data exchange capabilities for the WITSML format. WITSML is web-based, object-oriented, and built on W3C standards. It uses XML technology for data format and the SOAP protocol for data transport.

The WITSML teams produced a working prototype in July 2001 and rolled it out to industry at an SPE forum in August 2001. By early 2002, there were several commercial offerings, including Sperry-Sun's Insite database and application suite, Landmark's OpenWire data loader, and Schlumberger's InterACT data hub and Drilling Office suite. These products helped engineers make real-time adjustments to the wellbore during drilling (Fig. 3).

In June 2002, the WITSML steering board unanimously agreed in principle to transfer the WITSML drilling specifications to POSC for custody and ongoing support as of Oct. 1, 2002. The WITSML user community, therefore, became the POSC WITSML Special Interest Group (SIG).

POSC Fall 2002 conferences in London (October) and Houston (November) included WITSML seminars. These featured presentations from operating companies, software and service companies, tutorials, and recruiting for the WITSML SIG.

null

WITSML roadmap

In November 2002, a WITSML workshop in Stavanger offered presentations by operators and software suppliers and discussion about the transfer of custody to POSC. Each of the 70 participants completed a survey that was used to prepare an initial "road map" for future WITSML development. The WITSML SIG steering committee will refine the road map periodically.

Subsequent commercial products emerged, including Enterprise Enabler, by Stone Bond Technologies LP, which takes the output from WITSML applications and transforms and integrates the data into Oracle, SAP, or other enterprise systems, as well as other upstream applications, whether or not they support WITSML (OGJ, Feb. 24, 2003, p. 74).

WITSML V. 1.2 was completed in March 2003. Landmark introduced the RightTime system, a data receiver, server, and publisher supporting V. 1.2. This accepts data from upstream WITSML (pull or push) and WITS sources, stores the incoming data and publishes the data to subscribers, while providing secure access to stored data.

Down the road

As WITSML-enabled software systems proliferate, SIG participants expect WITSML to be used widely. According to BP's Matthew Kirkman, speaking at the SPE annual technical conference in Denver, Oct. 6, the current utilization of WITSML in the field is limited to about 60 Statoil wells, at least 10 other wells, and eight or nine rigs.

Other presentations offered various WITSML-enabled software, including: Knowledge Systems' DrillWorks WITSLINK software, part of Drillworks 2004 (real-time geopressure and wellbore stability analysis); and new updates from Schlumberger and Halliburton.

null

Developing protocols and tools enabling real-time access to data is an important topic in the industry.

Statoil's Andrew McCann said, "If you're just following the well path, real-time data is nice to have. If you're trying to influence the well path, it becomes critical."

Many companies are developing centralized operations centers that can accommodate multidisciplinary teams working with streaming real-time data (OGJ, Feb. 17, 2003, p. 49). Shell and Halliburton created a real-time operating center in New Orleans to support subsurface and drilling teams monitoring up to nine wells simultaneously. The 3,000 sq ft RTOC facilitates well planning, data analysis, and real-time intervention during drilling operations.

Sense Intellifield, a subsidiary of Sense Technology, Kristiansand, Norway, is among the companies now offering rig data management software and turnkey operations centers to the industry. Landmark introduced a mobile version of a real-time operations center, its portable RTOC, at the Denver SPE conference.

Maintaining security during data acquisition and transfer and subsequent collaboration will be a continuing concern. WITSML is built over the HTTP/S protocol and hence it is possible to communicate over an encrypted connection. The next revision of WITSML will also support authentication.

Acknowledgments

The author appreciates the assistance given by Melissa E. Symmonds, Schlumberger Information Solutions, and Sheldon Harbinson, Landmark Graphics Corp.

References

1.WITSML Project Functional Requirements, V. 1.06,

www.witsml.org/Docs/WITSMLRequirements106.doc, Feb. 5, 2001.

2.Kirkman, M.A., et al., "Wellsite Information Transfer Standard Markup Language, WITSML, an Update," SPE Annual Conference and Exhibition, Denver, Oct. 5-8, 2003.

3.Shields, J., "Comparison of DART and WITS Records," Baker Hughes, www.witsml.org/Docs/DART-WITS.htm, Oct. 31, 2000.

4.Weltevrede, B., "The OpenSpirit Alliance," SEG Annual Meeting, New Orleans, Sept. 14-17, 1998.

5.www.openspirit.com

6."Statoil Improves Well Positioning with Real-Time Link to OpenWorks," Landmark Solutions in Action, www.lgc.com/ news/solutionsinaction/, 2003.

Aim of the WITSML standard:"The 'right time' seamless flow of well site data between operators and service companies to speed and enhance decision-making."