Iraq Crude Oil Export Expansion heightens country's security

Oday al Quoraishi

UAE

Gary Vogler

Howitzer Consulting LLC

Centreville, Va.

Completion of Phase 1 of the Iraq Crude Oil Export Expansion (ICOEE) project enhanced the country's national security, providing needed redundancy to an export channel responsible for most of Iraq's revenue stream.

ICOEE

In 2007 almost all of Iraq's 1.6 million b/d of crude oil exports shipped through one southern subsea pipeline system. The system is so old and so badly corroded that one former senior South Oil Co. (SOC) manager said it should have started failing in the late 1990s. The last inspection of these subsea pipelines in 1989 found severe internal corrosion. SOC derated the maximum operating pressure in 1990 from 680 psi to a current 145 psi. Corrosion leaks have been limited to the waterline on the risers at the offshore terminal and were quickly repaired.

Just 5% of Iraq's exports in early 2007 were going through the country's only other export channel, the Iraq-Turkey (IT) Pipeline to Ceyhan, Turkey, in the north. Almost weekly attacks on the IT Pipeline cut exports through the route to a trickle. There were no other export pipelines in operation. This situation prompted US Gen. David Petraeus to highlight the export bottleneck to the Iraqi leadership as a national security issue and encourage a major export pipeline project, ICOEE.

The Gulf Region Division (GRD) of the US Army Corps of Engineers in 2007 issued a task order to Foster Wheeler under its Iraq oil sector reconstruction program management contract to perform a feasibility study for the project. This initial study used US government funding and contracting support. The Iraqi Ministry of Oil (MoO) actively participated and SOC took the leadership role as owner of the assets.

The study identified the urgency of the situation and recommended that the MoO quickly undertake a $6 billion project ($4 billion onshore, $2 billion offshore) to install new subsea pipelines and single point moorings (SPM) more than 50 km offshore. Oil Minister Hussein Shahrastani embraced the recommendations and declared this project his top priority in January 2008.

Phase 1 of ICOEE delivered first oil Mar. 8, 2012, onto the Maersk Hirado and will provide needed backup for Iraq's southern exports as its commissioning continues. Additional infrastructure installed over the next couple of years will increase Iraq's southern offshore export capacity by more than 4.5 million b/d.

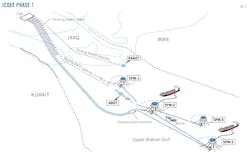

This article focuses on ICOEE Phase 1 (Fig. 1). Phases 2 and 3 are ongoing and only mentioned to provide a sense of the full picture of Iraq's southern offshore export infrastructure once all current awarded contracts are successfully completed. Onshore work is being managed by the State Company for Oil Projects (SCOP) and is not discussed in this article, although SCOP's pump installation projects will be essential for achieving full system capacity.

Responsibility, funding

In early 2008, Oil Minister Shahrastani appointed SOC to manage the $2 billion offshore segment of the export project and SCOP the $4 billion onshore work of installing new piping, tank storage, and pumping capacity. Both SOC and SCOP are state owned companies under the MoO.

The original funding for the feasibility study and follow up engineering came from the US government's reconstruction funds and amounted to about $2 million. Most of the funding for the offshore segment has come from the MoO's current year capital budgets and has exceeded $2 billion.

One notable exception is a low interest loan of about $550 million provided by the Japan International Cooperation Agency (JICA). The Japanese funds will be used for the JICA Sealine Project, Phase 3 of the offshore infrastructure expansion.

Offshore work

SOC awarded a front-end engineering and design (FEED) contract to Foster Wheeler in early 2009 as well as contracts for surveying the northern Arabian Gulf for unexploded ordinance (UXO) and gathering bathymetric and geotechnical data. SOC ordered long-lead procurement items such as pipe, meters, valves, and SPM using the Foster Wheeler procurement resources under their FEED contract. Foster Wheeler won additional contracts for project management of ICOEE Phases 1 and 2. Leighton Offshore Oil & Gas won the construction contracts for Phases 1 and 3, with Saipem SPA winning Phase 2.

Surveys

The northern Arabian Gulf is fairly shallow, with only a couple of narrow channels deep enough for large crude carriers to navigate. The Al Basrah Oil Terminal (ABOT) lies about 50 km from shore and close to the northern end of the deeper of those channels, the Khawr Al Kafka.

No commercial subsea survey work had been done in the northern Arabian Gulf in several decades, requiring surveys to be conducted before any design work could be finalized. SOC contracted with Coastal Marine Construction & Engineering Ltd (COMACOE) of India to conduct bathymetric and geotechnical surveys. By using side-scan sonar, these surveys provided the necessary information on the seabed topography and underlying sediments.

Core samples taken in about 60 locations consisted of both drop core samples and boreholes. The borehole samples were drilled to 40 or 70 m deep.

UXO surveying was also needed in areas where dredging and trench work would be required. This survey work was contracted to Maritime and Underwater Security Consultants (MUSC) of the UK.

More than 3,000 anomalies were detected in the surveyed area. MUSC defined an anomaly as an object on the sea bottom or at depths of several meters under the seabed detected by the sonar and requiring further investigation. MUSC physically inspected many of these anomalies and issued a certificate that each anomaly in the area of work was either cleared or an inert object.

Coalition and Iraqi Navies also assisted in this effort as they were doing similar work in the areas identified as Mine Danger Areas in the northern gulf at about the same time.

Very few of the anomalies were UXO and these were all considered small, posing no significant threat to dredging operations.

ICOEE Phase 1

Phase 1 of the project included installation of two 48-in. OD pipelines from the onshore terminal at Al Fao to near ABOT, about 50 km south of the shoreline in 30 m of water (Fig. 1). Two SPM were connected to the pipelines and became operational as part of Phase 1 commissioning. Two additional SPM are positioned but will not become operational until Phase 2 is commissioned.

Three additional 48-in. OD pipelines were also positioned as part of Phase 1 (but not made operational) from the beach valve station to beyond the tidal area about 8 km from the shore. These near-shore pipelines will be used for Phase 3 and future projects.

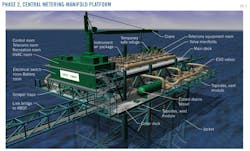

A subsea valve manifold is installed close to ABOT. Metering occurs at an onshore metering station installed during Phase 1. An offshore metering station will be installed during Phase 2 (Fig. 2). The pipelines are looped to facilitate future inspections and maintenance.

The system is designed to operate at high pressures, vs. operating pressures of about 10 bar in the existing system. Each SPM will load about 900,000 b/d of crude oil, assuming high pressures and normal oil tanker loading operations. Phase 1 will therefore increase offshore export capacity by about 1.8-million b/d once the SCOP-installed onshore pump capacity is available.

Leighton Offshore Oil & Gas will operate these facilities for a few months, after which the SPM will be operated and maintained for 3 years by a not-yet-identified contractor.

The Phase 2 scope of work includes fabrication and installation of a central metering and manifold platform (CMMP) adjacent to ABOT (Fig. 3). The CMMP will receive oil from Al Fao through the two 48-in. pipelines installed in Phase 1. Oil will be distributed to the four SPM also installed during Phase 1. Control and metering of SPM operations will take place on the CMMP. The system is designed to load 900,000 b/d through each of the four SPM at design pressures of 90 bar.

The JICA-funded Sealine Project is Phase 3 of the offshore export infrastructure expansion. This phase includes installation of a third 48-in. OD pipeline from shore to a valve station near ABOT (Fig. 4). From there pipelines will be installed to ABOT, Khor Al Amaya Oil Terminal (KAAOT), and another SPM.

Phase 1 pipeline

Leighton Offshore Oil & Gas installed the offshore pipeline using the conventional S-Lay method in water depths of 5-30 m. The near-shore pipe installation provided some technical problems.

Iraq has a very large tidal area along its limited shoreline and the soil in the Al Fao area is primarily silt accumulated from the Shatt al Arab over thousands of years. The Al Fao soil consistency, similar to toothpaste, requires a lot of piling work for any foundation.

Near-shore pipeline installation used a shore-pull method over a 3.5 km distance, with buoyancy bags used to float the 48-in. OD pipe over a dredged canal. A lateral pile design anchored the pulley to shore and a steel cable from the Leighton Stealth pipelay barge pulled the pipe to shore. The dredged canal was 3.5 km long, 70 m wide, and had a depth of 5.25 m at low tide (Fig. 5).

ILVA SpA manufactured the pipe in Italy and the offshore pipe was sent to the Arabian Gulf for concrete coating. The pipe installed offshore meets DNV-SAW-450 standard. Leighton buried about 9,000 joints with a length of 12.5 m each at a minimum of 3 m into the seabed. The onshore pipe meets API 5L X65 standard.

Phase 1 SPM

A total of four SPM are part of Phase 1, but only two are operating (Fig. 1). Each lies in the same deepwater channel of the northern Arabian Gulf (Khawr Al Kafka), with substantial dredging required to clear 26-m depth at low tide over a radius of 1,300 m around each SPM, the necessary SPM navigation radius for loading VLCCs, the vessel-size normally loaded by SOC.

SBM Offshore designed the SPM with the catenary anchor leg mooring (CALM) system. The average loading rate of 900,000 b/d for each SPM includes vessel maneuvering and pre- and post-loading operations. Each buoy is 13 m in diameter, more than 5 m high, and weighs 300 tonnes. Six 265-m chains attached to a 26-m pile anchor the buoys.

Installed on the seabed under each SPM is a pipeline end manifold (PLEM) 17 m long, 9 m wide, and weighing 215 tonnes. A suction-base foundation anchors each PLEM at a depth of 31 m. Each PLEM has two 48-in. diameter valves and two 24-in. diameter valves. All valves have a 600 lb rating and are operated hydraulically.

Fiscal meters

Fiscal metering systems operate in accordance with the Iraqi National Fiscal Metering Code and the International Fiscal Metering Codes. The systems measure flow rates of 17,000 cu m m/hr based on the Emerson time-of-flight ultrasonic flow meters, Model No. 3804. Each metering skid has 48-in. diameter inlet and outlet headers and five 16-in. diameter meter runs.

Crossover connections from the outlet of each duty meter run to the inlet of the fifth meter run, which provides both standby and master meter functions. Each system has a metering panel with five flow computers, one for each meter run, and a supervisory computer for overall control and monitoring of the metering skids.

Phase 2 CMMP

The central metering and measurement platform (CMMP) will consist of a jacket supporting a three-story topsides structure (Fig. 3). The jacket will weigh about 2,100 tons, measure 40 m high and be supported by 70-m piles in water 30 m deep. The topsides will weigh 9,300 tons with the main deck 28 m above low tide. The main deck will include four metering-sampling skids, three scraper receivers, one scraper launcher, a hydraulic power unit for subsea valve operation, a platform crane, an emergency diesel generator, a control room, and a safe room.

Difficulties

Both the project leadership at SOC and the project champions at MoO had to overcome significant difficulties in moving the project forward, including security, resource capacity, lack of business processes, engaging foreign companies, UXO, dredging, leadership turnover, and the need to complete all work quickly.

• Security. Iraq's recent security history is well known. 2007 was a difficult time to kick off a multibillion dollar capital project in the oil sector, even one as focused on national security objectives as ICOEE. Attackers killed key MoO leaders and kept others under constant threat. The upstream deputy minister was kidnapped in summer 2007 and the oil infrastructure was the target of many attacks.

• Resource capacity. ICOEE was one the largest projects in MoO history. The last time the ministry had attempted such a project was in the late 1980s when the Iraq Pipeline through Saudi Arabia (IPSA) was constructed. Only a few of the people involved in that project remained as active employees. The ministry lost many experienced employees in the early 1990s and again after 2003.

SOC was not immune to the loss of resources, but its losses had been much less than other ministry operating companies, and SOC demonstrated a capacity to work with the US Army Corps of Engineers and their US funded oil sector contractors to complete large and important capital projects that helped keep production and exports flowing in the south before 2008.

• Business processes. Normal business processes that international oil companies and national oil companies take for granted did not exist in the MoO, including standardized procurement and payment systems. Since Iraq was under sanctions before 2003, foreign procurements were handled by the United Nations under the Oil for Food program.

The initial contracts in 2009 for a FEED contract and subsea survey work took 1 year to negotiate and sign. These were the first major contracts with foreign contractors by the post-2003 Oil Ministry, and issues such as how to resolve contractual disputes or how much liability the foreign contractor should accept were contentious and took a long time to resolve.

Once the various committees approved the contracts, payment processes became an issue. Iraq uses a letter of credit payment system established in 2003 when the Trade Bank of Iraq (TBI) was established. Funds for a specific contract are sent from the Central Bank to TBI after authorization from the Finance Ministry. The funds stay on deposit with TBI until the detailed administrative work gets properly completed with the contractor's bank.

The ICOEE project garnered top-priority status with the TBI, but expediting letters of credit continued to be a challenge for SOC project leadership and required much of their time and focus.

• Foreign companies. Security issues made it difficult to find foreign companies willing to invest or participate in the Iraqi oil sector before the 2009 bid rounds that brought back the major international oil companies. Except for US Army Corps of Engineers' contractors, foreign companies were hesitant to engage in Iraq's oil sector.

When the MoO signed large production contracts with oil companies such as BP, ExxonMobil, ENI, Shell, Lukoil, etc. in 2010-11, many of the oil service companies returned to Iraq and finding foreign contractors to support ICOEE became less of an issue.

• UXO. The status of the sea bottom in the northern Arabian Gulf was an unknown risk requiring attention before any dredger or pipelay company would commit resources to ICOEE. Iraq had experienced three wars since the last new pipelines were installed in 1975. Dredging companies are familiar with working around small UXO and have equipment for mitigating small explosions. They needed assurances, however, that large UXO with the explosive strength to sink their vessels did not exist in the northern Gulf.

• Dredging requirements. Each SPM required some level of dredging to meet the VLCC's minimum radius requirements of 1,300 m for turning and navigational needs. Placing the SPM where dredging costs could be reduced while not interfering with the navigation on the main channel to ABOT was a significant technical challenge.

• Management stability. The MoO has experienced a lot of personnel turnover since 2003. The ICOEE project champion in Baghdad changed from one deputy minister to another in 2009 and that deputy (Abdul Karim al-Luaibi) eventually became oil minister in early 2011. The SOC director general changed three times during 2008 and 2009.

Project leadership changes often cause delays and cost overruns in mega projects and these personnel changes added to ICOEE project leadership difficulties. Delays resulting from these changes, however, were minimized primarily because SOC Director General Dheyaa Jaafar did not make significant modifications to the ICOEE project team under the leadership of Oday Al Quoraishi and Saad Mohammed.

• "Time is of the Essence." This legal term used in some Iraqi contracts was not used in any of the SOC contracts, but the spirit of its meaning prevailed throughout the project. Project leadership faced the challenge of pushing forward as quickly as possible knowing that the current corroded pipeline system could start failing at any time. This alone was enough incentive to expedite the project.

Time pressure increased in 2010, however, when SOC and the international oil companies submitted plans for increasing production from the large fields in the south, making it obvious that the export infrastructure would soon become the bottleneck for these increases and opportunity costs would be incurred until Phase 1 became operational.

Physical constraints started as early as first-quarter 2011 when weather outages at the loading platform forced shut-in of many of the producing wells in the south. The lack of onshore storage capacity coupled with limited export throughput capacity resulted in shutting in production. This problem persisted throughout 2011 during weather outages at ABOT.

With Phase 1 of ICOEE complete, however, SOC and the international oil companies have begun ramping up production capacity in the south at a pace never experienced by Iraq in the past.

Acknowledgment

The authors thank the ICOEE team at Foster Wheeler for its assistance with this article.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com