New NGL-recovery process provides viable alternative

View Article as Single page

Ethane-rich cycle

The advanced refrigeration NGL extraction process can economically achieve deep NGL extraction from most natural gas streams. Using conventional closed-loop mechanical refrigeration combined with an open-loop mixed refrigeration cycle, this process can provide performance comparable to that of advanced turboexpander technologies but with much lower CAPEX and OPEX.

Unique about the IPOR process is its open-loop ethane-rich mixed refrigeration cycle. This refrigerant, extracted from the feed gas itself, is a mixture of predominantly ethane with lower concentrations of methane, propane, and other feed-gas constituents.

This refrigeration cycle serves a dual purpose: producing the cryogenic refrigeration for the process to enable lower temperature operation while at the same time providing a reflux stream to the fractionation column, the combination of which produces high product extraction and thermal efficiencies.

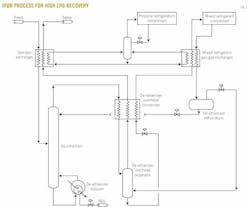

The extraction process can be configured in several ways, depending on the feed stream, site conditions, and project objectives. Fig. 1 depicts one configuration of the IPOR technology recommended for high recovery LPG applications.

Feed gas, at a pressure typically 300-550 psig, is initially cooled and partially condensed in the gas-gas heat exchanger by cross exchange with cold residue gas and propane refrigerant. A conventional brazed aluminum heat exchanger appears in the flow diagram; however, shell-and-tube exchangers can also be used for this service.

The cooled and partially condensed feed-gas stream is then fed to the middle section of the de-ethanizer, which uses either trays or packing or a combination of these to effect the desired product separation. Below the feed tray, the stripping section of the column selectively removes the lighter fractions to meet product specifications, which normally is 2-5% ethane in the recovered propane. Heat for the separation is provided by the de-ethanizer reboiler, which is a conventional shell-and-tube heat exchanger, with the heat supplied from the plant heating medium system.

In the upper section of the de-ethanizer, above the feed tray, the cooled feed gas flows counter-currently to the reflux stream, which is fed to the top tray in a conventional manner. The reflux provides additional cooling for the feed-gas stream and also selectively absorbs the propane and heavier components from the gas, thereby providing high product recovery efficiencies.

The overhead gas stream from the de-ethanizer, at this point in the process containing primarily the light ends from the feed-gas stream and a small portion of the propane, is further cooled in the de-ethanizer overhead condenser by cross exchange with cold residue gas and the ethane-rich mixed refrigerant stream.

The cooled and partially condensed gas stream flows to the de-ethanizer overhead separator. The liquid from this separation, a mixture of methane, ethane, and propane, is used as the refrigerant for the open-loop mixed refrigerant cycle. The de-ethanizer overhead separator therefore has a twofold function: It acts as a conventional two-phase gas-liquid separator, and it provides surge capacity for the liquid mixed refrigerant system.

From the de-ethanizer overhead separator, the pressure of the liquid mixed refrigerant is reduced, creating a Joule-Thomson refrigeration effect: This cold stream provides the desired cooling in the de-ethanizer overhead condenser. The pressure of the low-pressure mixed refrigerant, usually in the range of 100-200 psig, is selected to satisfy the cooling requirements in the de-ethanizer overhead condenser and to minimize the compression power requirements.

From the de-ethanizer overhead condenser, the mixed refrigerant stream is heated further as it flows through the mixed refrigerant gas-gas exchanger to the mixed refrigerant compressor. The discharge pressure of this compressor is normally about 40 psig higher than the operating pressure of the de-ethanizer.

The mixed refrigerant compressor is of conventional design and can be either reciprocating, centrifugal, or screw type, depending upon project requirements and customer preferences. Drivers may be gas turbine, gas engine, or electric motor. The compressor can be packaged with driver, scrubbers, and discharge cooler following standard industry practice.

Displaying 2/6

View Article as Single page